Honeycomb structure graphene/ZnO nanorod composite film, manufacturing method and application

A zinc oxide nanorod and graphene film technology is applied in the field of honeycomb structure graphene/zinc oxide nanorod composite film and preparation, and can solve the problem of inability to form a multi-level structure, unavoidable aggregation of nanoparticles, and lack of nanoparticle distribution and orientation. control and other problems, to achieve the effect of obvious photoelectric conversion efficiency, improving photoelectric conversion efficiency, and improving photoelectric response performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1) Preparation of graphene oxide / dioctadecyldimethylammonium bromide composite:

[0037] a) Add 1g of graphite powder (45 μm in particle size), 1.7g of potassium persulfate and 1.7g of phosphorus pentoxide into 8mL of concentrated sulfuric acid (98% by mass) successively, heat and stir at 80°C, stop heating after 6 hours, After the mixture was cooled to room temperature, it was separated by filtration through a cellulose acetate membrane with a pore size of 0.2 μm, washed with deionized water, and dried overnight to obtain pre-oxidized graphite;

[0038] b) Disperse the pre-oxidized graphite in 30mL of cold (0°C) concentrated sulfuric acid (98% by mass), then add 5g of potassium permanganate while stirring, continue stirring for 2 hours at 35°C, and then add 95mL of deionized water Dilute, then add 2mL hydrogen peroxide aqueous solution (mass percentage 30%), the bright yellow product that obtains; The product is filtered and successively with dilute hydrochloric acid s...

Embodiment 2

[0052] As in the steps of Example 1, the difference is that step 1c) of Example 1 is to use dioctadecyldimethylammonium bromide as a surfactant to electrostatically interact with graphene oxide to form a complex, while Example 2 It uses dihexadecyl dimethyl ammonium bromide as a surfactant to electrostatically interact with graphene oxide to form a complex. Further adopt the same method to prepare honeycomb structure graphene / zinc oxide nanorod composite film.

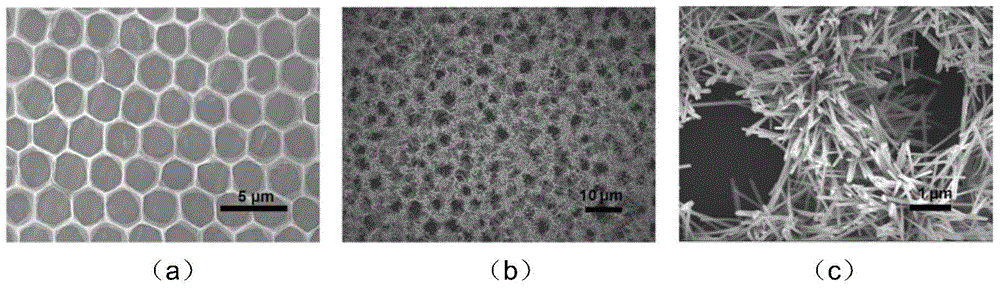

[0053] The average size of holes in the prepared composite film is 3 μm, the average distance between holes is 0.5 μm, the average length of zinc oxide nanorods is 1.0 μm, and the average diameter is 150 nm.

Embodiment 3

[0055] As in the steps of Example 1, the difference is that the step 2) of Example 1 uses chloroform as the organic solvent, and the honeycomb structure graphene film is prepared by volatilizing the chloroform solution under the condition of relative humidity of 85%. 3 is to adopt dichloromethane as solvent to prepare honeycomb structure graphene film. Further adopt the same method to prepare honeycomb structure graphene / zinc oxide nanorod composite film.

[0056] The average size of holes in the prepared composite film is 2.0 μm, the average distance between holes is 1.5 μm, the average length of zinc oxide nanorods is 1.0 μm, and the average diameter is 150 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com