A kind of preparation method for the nano electrode material of supercapacitor

A supercapacitor and nano-electrode technology, applied in the field of electrochemistry, can solve the problems of reducing electrochemical performance, and achieve the effect of low price, wide source and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A kind of preparation method for the nanometer electrode material of supercapacitor, carry out according to the following steps:

[0026] (1) Preparation of melamine-phenolic resin precursor: Measure 0.5 mL of concentrated ammonia water (25wt%), 40 mL of absolute ethanol and 99.5 mL of deionized water to form a mixed solvent, and heat it while stirring under reflux condensation conditions (stirring rate is 2100rpm , heating power was 200 W), the temperature was raised to 70°C, 0.55 g of resorcinol and 0.74 mL of formaldehyde solution (37 wt %) were added after 30 min, and 0.315 g of melamine and 0.55 mL of formaldehyde solution (37 wt %) were added after 30 min of reaction. wt %), and continued to react for 24 h; then, the above mixed solution was transferred to a polytetrafluoroethylene autoclave at 120 °C for static hydrothermal reaction for 24 h; the added monomers resorcinol, melamine and formaldehyde were Polymerize to form melamine-phenolic resin; separate the rea...

Embodiment 2

[0032] Change the activator to K 2 CO 3 , and all the other steps are the same as in Example 1.

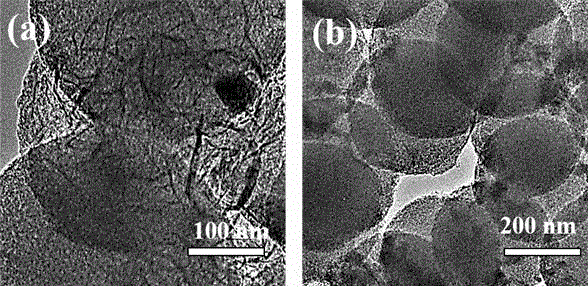

[0033] The transmission electron microscope (TEM) image of the obtained electrode material is shown in figure 1 b, the results show that the obtained nano-electrode material contains a large number of micropores and mesopores inside and on the surface, with high purity and basically no impurities, but no highly crystalline carbon nanosheets. Therefore, when the material is used as an electrode material for a supercapacitor , the specific capacitance is lower than that of the electrode material activated by KOH.

Embodiment 3-5

[0035] The amount of melamine was changed to 0.504, 0.63, 1.26 g in turn, and the corresponding amount of formaldehyde solution was changed to 0.884, 1.105, 2.21 mL when adding melamine and formaldehyde solution. All the other steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com