Purification method of tobacco stem extracting solution in paper-making reconstituted tobaccos

A technology for reconstituting tobacco leaves and purifying method, which is applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of excessive tobacco stem inventory, lack of raw materials of tobacco crushed powder, etc., and achieve the effects of sensory quality improvement, sensory quality improvement, and tight integration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: the operation steps are as follows:

[0021] (1) preparing a clarifying agent for the tobacco stem extract produced in the production process of reconstituted tobacco leaves, the clarifying agent is composed of two independent components A and B, wherein component A is composed of 1.0 part of chitosan and 0.25 part of gelatin; Component B is composed of 1.0 parts of sodium alginate and 2.0 parts of potassium sodium tartrate. Weigh each raw material according to the weight ratio of component A, mix evenly, take 5 parts and dissolve in 95 parts of 1% acetic acid solution to form liquid I, and set aside; weigh each raw material according to the weight ratio of component B, mix evenly, take 5 parts 1 part was dissolved in 95 parts of distilled water to form II liquid, which was set aside. In the above-mentioned procedure, can adopt the chitosan that deacetylation degree is 90%, average molecular weight is 9K; Can select the average molecular weight as the gel...

Embodiment 2

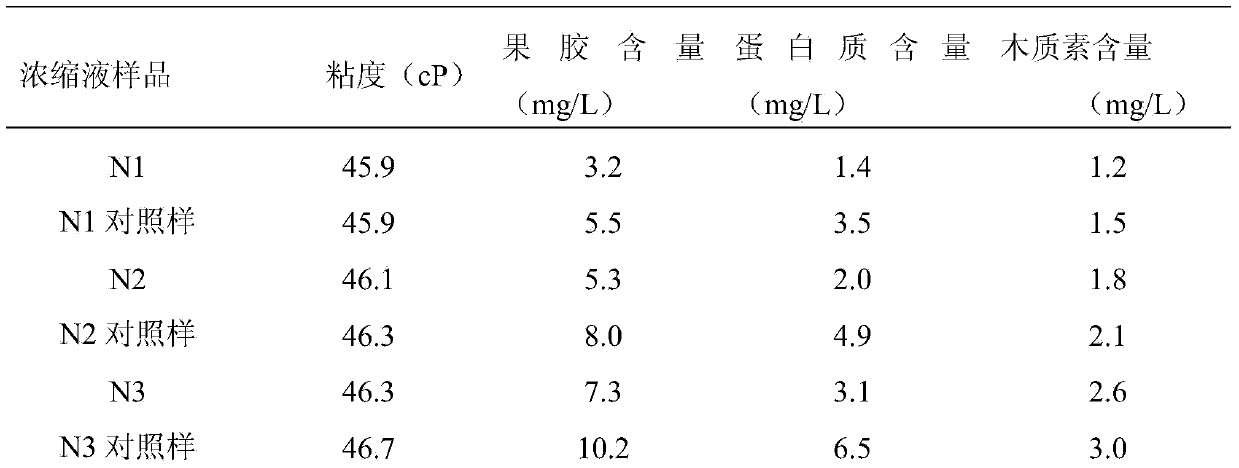

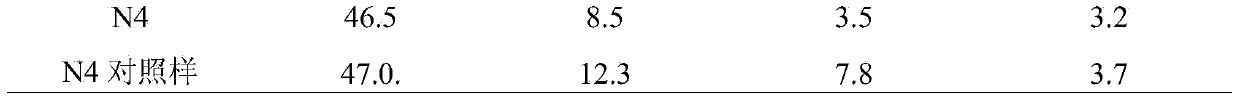

[0026] The steps are the same as in Example 1, except that the weight ratio of the tobacco stem extract liquid to the tobacco powder extract liquid in step (4) is 10:90, the concentrated liquid is marked as N2, and the cigarette sample is marked as J2.

Embodiment 3

[0028] The steps are the same as in Example 1, except that the weight ratio of the tobacco stem extract liquid to the tobacco dust extract liquid in step (4) is 15:85, the concentrated liquid is marked as N3, and the cigarette sample is marked as J3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average molecular weight | aaaaa | aaaaa |

| Average molecular weight | aaaaa | aaaaa |

| Average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com