Colloid-based photonic crystal anti-fake pattern preparation method

A technology of colloidal photonic crystals and colloidal particles, which is applied in the reproduction/marking method, the printing and printing of special varieties of printed matter, can solve the problems of long technology generation time, complicated operation steps, cracking and imitation, etc., and achieve convenient and fast detection. , Simple preparation, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

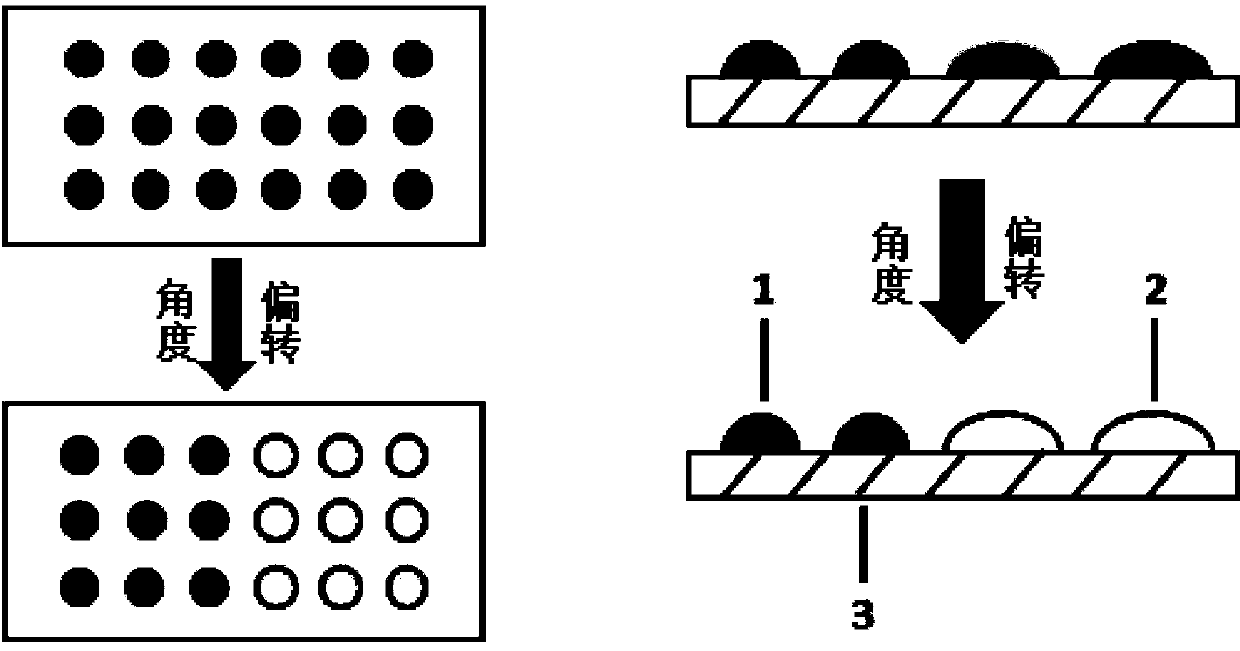

[0038] Example 1: Preparation of colloidal photonic crystal anti-counterfeiting patterns

[0039] 1. Preparation of colloidal photonic crystal solution:

[0040] Add monodisperse solid silica colloidal nanoparticles with a diameter of 220nm into a mixture of ultrapure water and ethylene glycol with a volume ratio of 4:1, adjust the mass fraction of silica to 20%, and ultrasonically disperse;

[0041] 2. One-time processing of the printed substrate

[0042] Choose the smooth surface of a single-sided polished silicon wafer as the printing substrate. After the silicon wafer is cleaned and treated with a plasma instrument to make the contact angle 0°, it is placed in a sealed glass dish with a diameter of 1dm, and 300ul propyl triethoxylate is added. base silane (triethoxypropylsilane), heated at 60°C for 1h, and treated its contact angle to 50°;

[0043]3. Ink printing

[0044] Use the colloidal photonic crystal solution prepared in step 1 as ink to inject into the ink cartri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com