Environment-friendly production method for enhancing trehalose yield of beer waste yeast under stress conditions

A technology for waste beer yeast and a production method, applied in the field of environmental protection production, can solve the problems of low extraction rate, difficult impurity dissolution, long extraction time of trehalose, etc., and achieve the effect of short processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

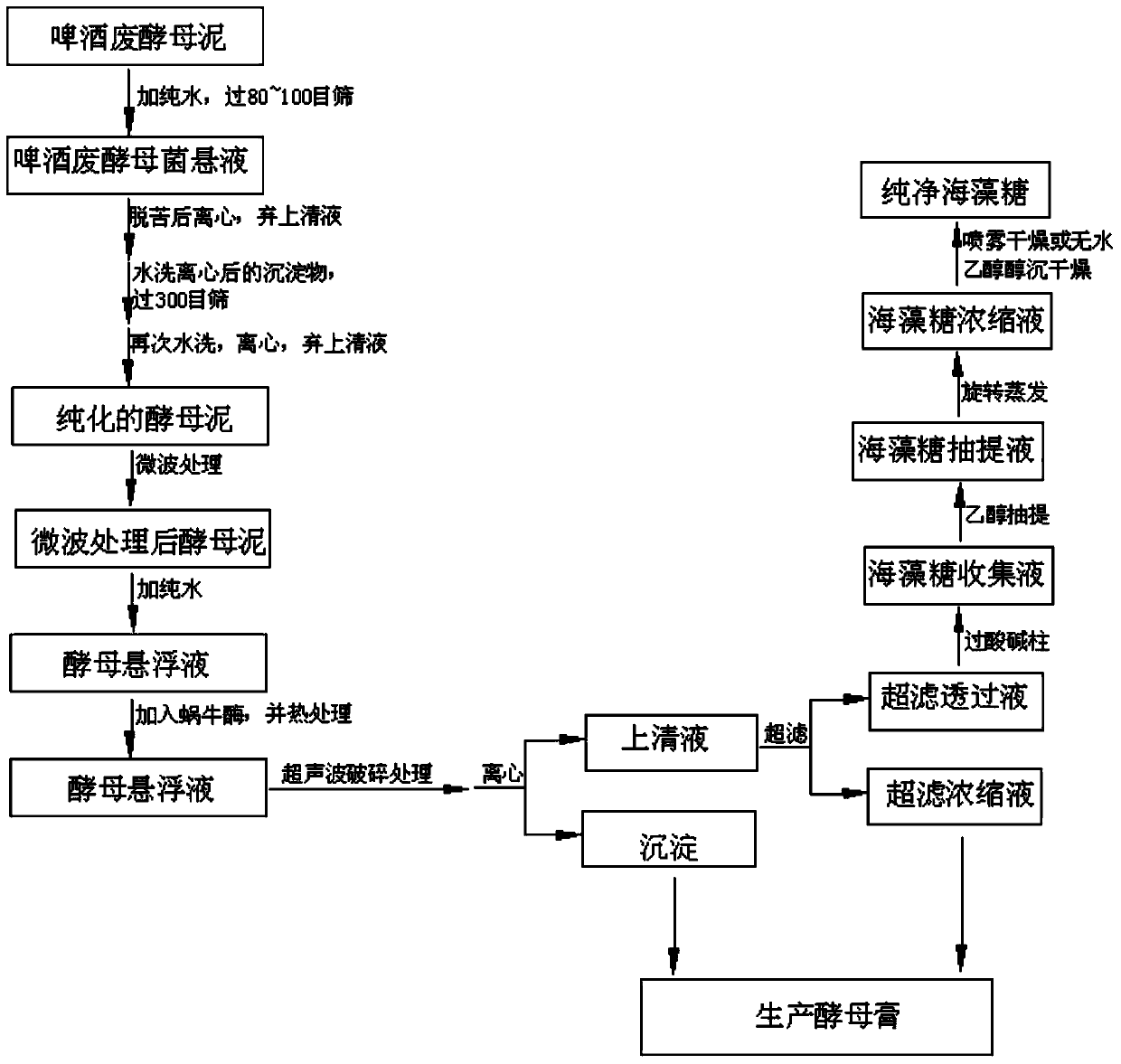

[0033] Such as figure 1 Shown, a kind of environment-friendly production method that utilizes stress condition to improve the trehalose yield of beer waste yeast comprises the following steps:

[0034] 1) Microwave treatment

[0035] First, debitterize and purify the waste beer yeast sludge. The debittering and purification of the waste beer yeast sludge includes the following steps: add pure water to the waste beer yeast sludge (the weight ratio of beer waste yeast sludge to pure water is 1:3), after 80 ~ 100 mesh sieve to obtain yeast suspension; add tartaric acid to the obtained yeast suspension, so that the mass fraction of tartaric acid is 5%, stir for 60 minutes to remove bitterness, and centrifuge to discard the supernatant; 300-mesh sieve, washed with water again, and centrifuged to obtain purified and debittered yeast sludge; then place the debittered and purified yeast sludge in a 500W microwave oven for 5 minutes;

[0036] 2) heat treatment

[0037] Add pure wate...

Embodiment 2

[0045] Such as figure 1 Shown, a kind of environment-friendly production method that utilizes stress condition to improve the trehalose yield of beer waste yeast comprises the following steps:

[0046] 1) Microwave treatment

[0047] First, debitterize and purify the waste beer yeast sludge. The debittering and purification of the waste beer yeast sludge includes the following steps: add pure water to the waste beer yeast sludge (the weight ratio of beer waste yeast sludge to pure water is 1:3), after 80 ~ 100 mesh sieve to obtain yeast suspension; add tartaric acid to the obtained yeast suspension, so that the mass fraction of tartaric acid is 5%, stir for 60 minutes to remove bitterness, and centrifuge to discard the supernatant; 300-mesh sieve, washed with water again, and centrifuged to obtain purified and debittered yeast sludge; then place the debittered and purified yeast sludge in a 500W microwave oven for 5 minutes;

[0048] 2) heat treatment

[0049] Add pure water ...

Embodiment 3

[0057] Such as figure 1 Shown, a kind of environment-friendly production method that utilizes stress condition to improve the trehalose yield of beer waste yeast comprises the following steps:

[0058] 1) Microwave treatment

[0059] First, debitterize and purify the waste beer yeast sludge. The debittering and purification of the waste beer yeast sludge includes the following steps: add pure water to the waste beer yeast sludge (the weight ratio of beer waste yeast sludge to pure water is 1:3), after 80 ~ 100 mesh sieve to obtain yeast suspension; add tartaric acid to the obtained yeast suspension, so that the mass fraction of tartaric acid is 8%, stir for 30min to remove bitterness, and centrifuge to discard the supernatant; 300-mesh sieve, washed with water again, and centrifuged to obtain purified and debittered yeast sludge; then place the debittered and purified yeast sludge in a 600W microwave oven for 1 min;

[0060] 2) heat treatment

[0061] Add pure water to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com