Chelating resin adsorbing material and preparation method thereof

An adsorption material, chelating resin technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve problems such as the inability to increase adsorption capacity, achieve good treatment effect, and simple synthesis process steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

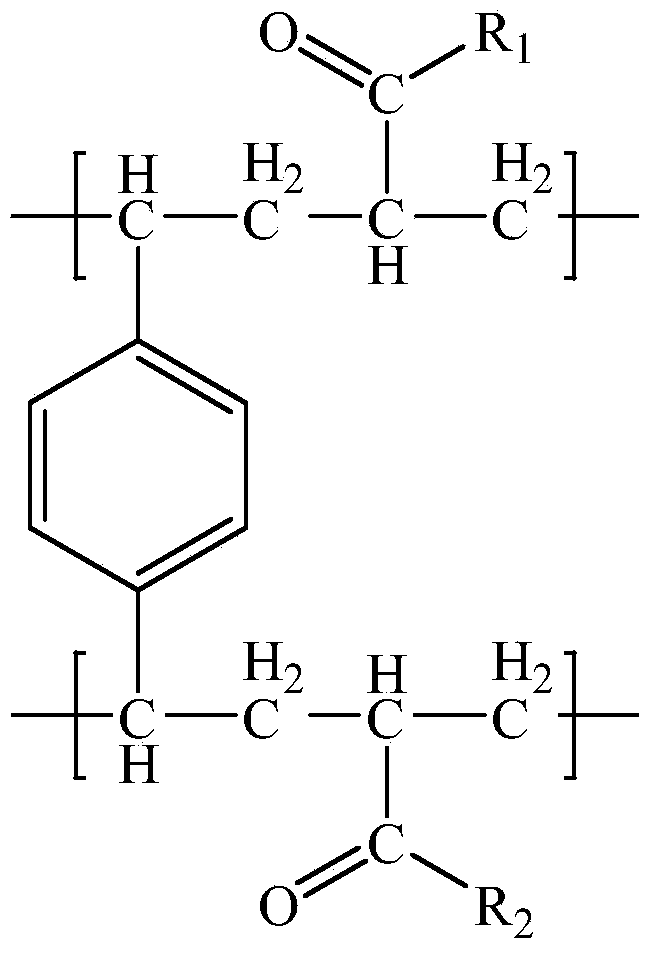

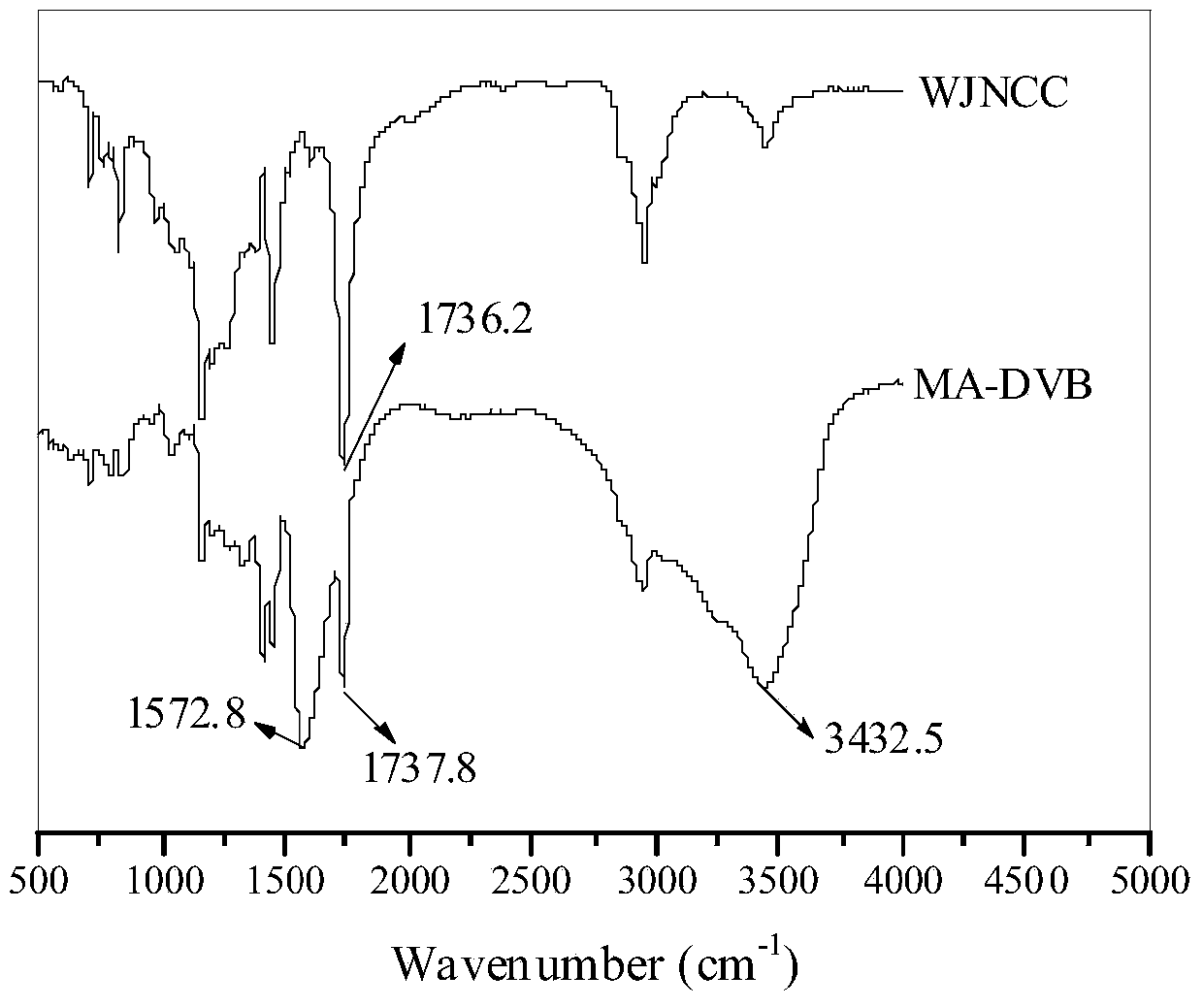

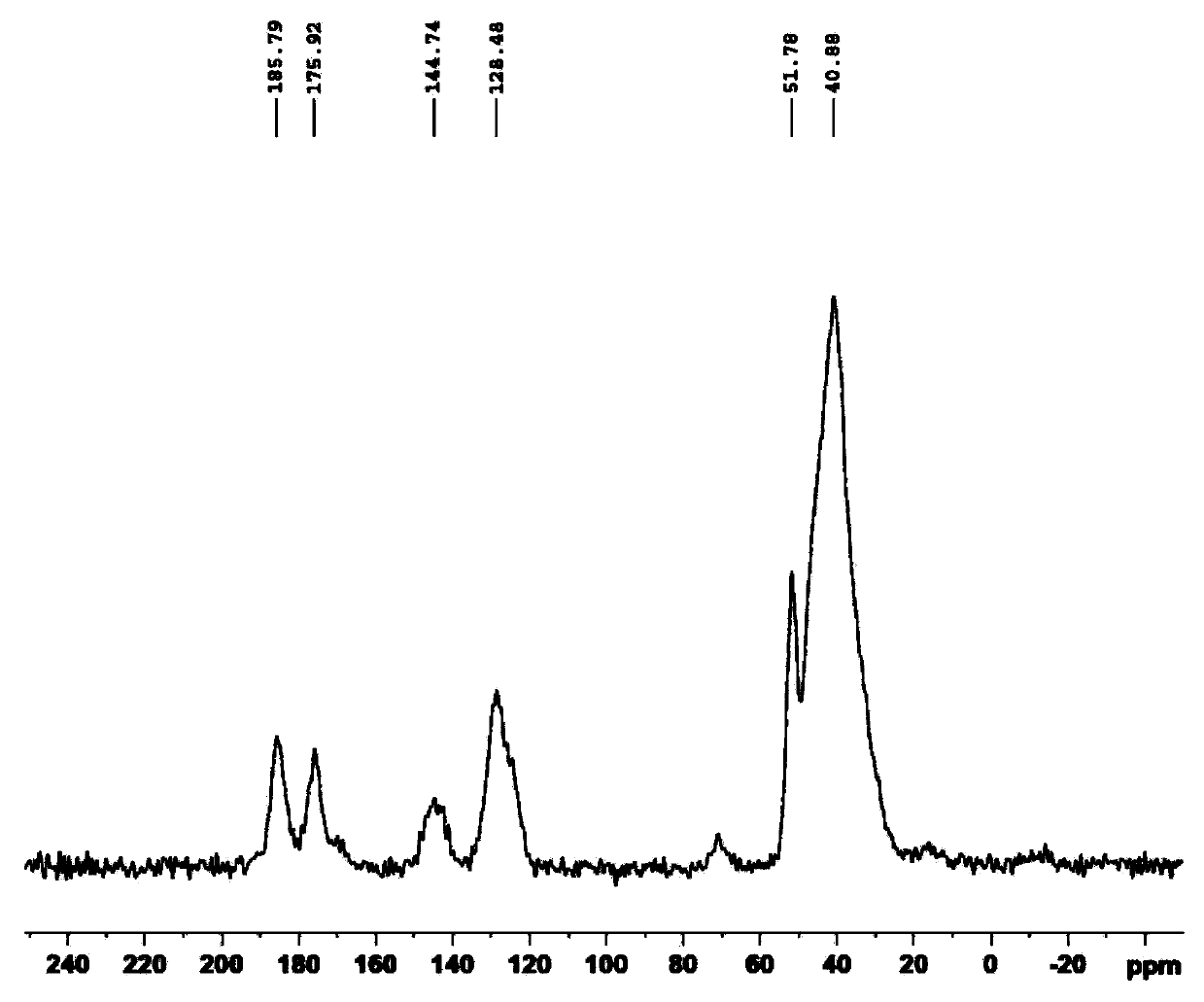

Image

Examples

Embodiment 1

[0031] Prepare an emulsion with 90mL methyl acrylate, 9mL divinylbenzene, 6g gelatin, 35mL n-heptane, and 400mL distilled water. Pour the prepared 500mL emulsion into a 1000mL three-necked flask, add 1g of benzoyl peroxide, heat in a water bath at 95°C, and stir the reaction at a speed of 60r / min for 8 hours, and perform solid-liquid separation of the copolymerized spheres obtained by the reaction, and use ethanol Wash and dry under vacuum at 50°C. Take 10g of potassium hydroxide, 15g of hydroxylamine sulfate, 5mL of polyoxyethylene oleate, and 500mL of distilled water to make a solution, pour it into a 1000mL three-necked flask, add 10g of copolymerized balls, mix, and react at a stirring rate of 60r / min at 45°C After 16 hours, the product was filtered, washed with distilled water, and vacuum-dried at 50° C. to obtain a finished chelating resin adsorption material.

[0032] Its physical and chemical properties of the chelating resin adsorption material prepared by the presen...

Embodiment 2

[0036] Prepare an emulsion by mixing 90 mL of methyl acrylate, 11 mL of divinylbenzene, 6 g of polyvinyl alcohol, 40 mL of ethyl acetate, and 400 mL of distilled water. Pour 500mL of the emulsion into a 1000mL three-neck flask, add 2mL of di-tert-butyl peroxide, heat in a water bath at 94°C, and stir at a speed of 60r / min for 9 hours, then separate the copolymerized spheres from the reaction into solid and liquid, and wash with ethanol , dried under vacuum at 45°C. Take 15g of sodium hydroxide, 10g of hydroxylamine hydrochloride, 5mL of polyoxyethylene sorbitan oleate, and 500mL of distilled water to make a solution, pour it into a 1000mL three-necked flask, add 10g of copolymerized balls and mix, at 48°C at 60r / min React at a stirring rate for 15 hours, filter the product, wash it with distilled water, and dry it under vacuum at 45°C to obtain a finished product of the chelating resin adsorption material. Its physical and chemical properties of the chelating resin adsorption...

Embodiment 3

[0041] Mix 90mL methyl acrylate, 8mL divinylbenzene, 6g polyethylene wax, 30mL toluene, and 400mL distilled water to make an emulsion. Pour 500mL of the emulsion into a 1000mL three-necked flask, add 2g of azobisethylbutyronitrile, heat in a water bath at 93°C, and stir at a speed of 60r / min for 10 hours, then separate the copolymerized spheres from the reaction into solid and liquid, and wash with ethanol , dried under vacuum at 40°C. Take 12g of sodium hydroxide, 12g of hydroxylamine sulfate, 5mL of diglycerol polypropylene glycol ether, and 500mL of distilled water to make a solution, pour it into a 1000mL three-necked flask, add 10g of copolymerization balls, mix, and react at a stirring rate of 60r / min at 52°C for 14 hours, the product was filtered, washed with distilled water, and vacuum-dried at 40°C to obtain the finished product of the chelating resin adsorption material. Its physical and chemical properties of the chelating resin adsorption material prepared by the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com