Tough self-repair metal anti-corrosion paint and preparation method thereof

A metal anti-corrosion and self-repair technology, which is applied in anti-corrosion coatings, coatings, epoxy resin coatings, etc., can solve the problems that are not conducive to the sustainable development of the national economy, poor anti-fouling and alkali resistance, and threaten the health of workers and other issues, to achieve excellent low-temperature curing performance and solvent resistance, good welding and cutting performance, excellent impact resistance and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

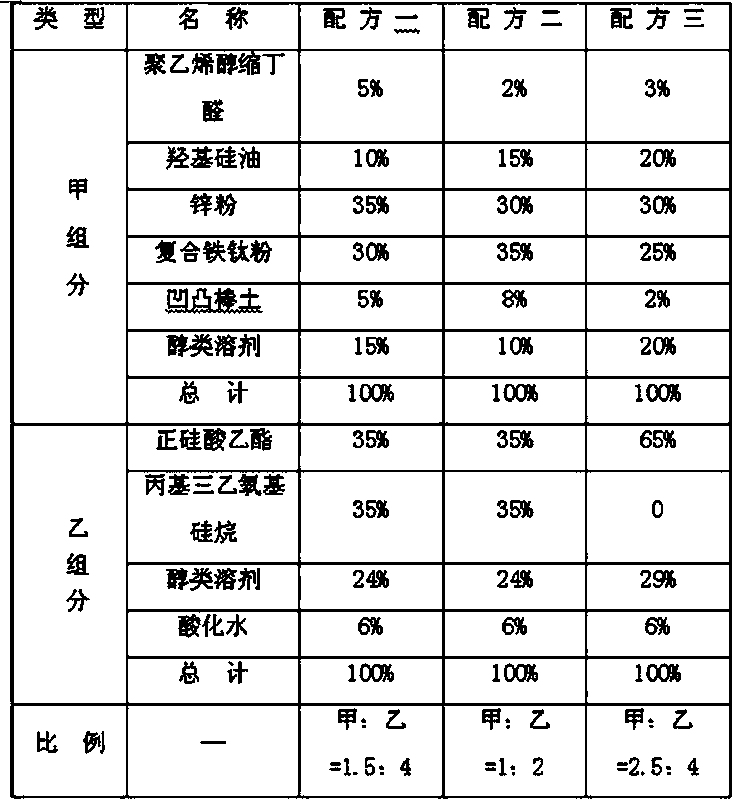

Embodiment 1

[0053] Embodiment one (acid preparation method):

[0054] The following components are proportioned according to weight percentage and mixed uniformly according to certain conditions:

[0055] A component:

[0056] Polyvinyl butyral: 2-5%

[0057] Hydroxy silicone oil: 10-20%

[0059] Composite iron and titanium powder: 25-35%

[0060] Attapulgite: 2-8%

[0061] Alcohol solvent: 15-35%

[0062] The sum of the above parts is 100%.

[0063] B component:

[0064] Alkylsilyl esters: 50-75%

[0065] Alcohol solvent: 10-35%

[0066] Acidified water: 5-15%

[0067] The sum of the above parts is 100%.

[0068] A component: B component = 1.5-2.5 : 4

[0069] Described preparation method comprises the following steps:

[0070] (1) Preparation of component A: polyvinyl butyral: 2-5%, hydroxyl silicone oil: 10-20%, zinc powder: 30-35%, composite iron-titanium powder: 25-35%, attapulgite Soil: 2-8%, alcohol solvent: 15-35% mixed to ...

Embodiment 2

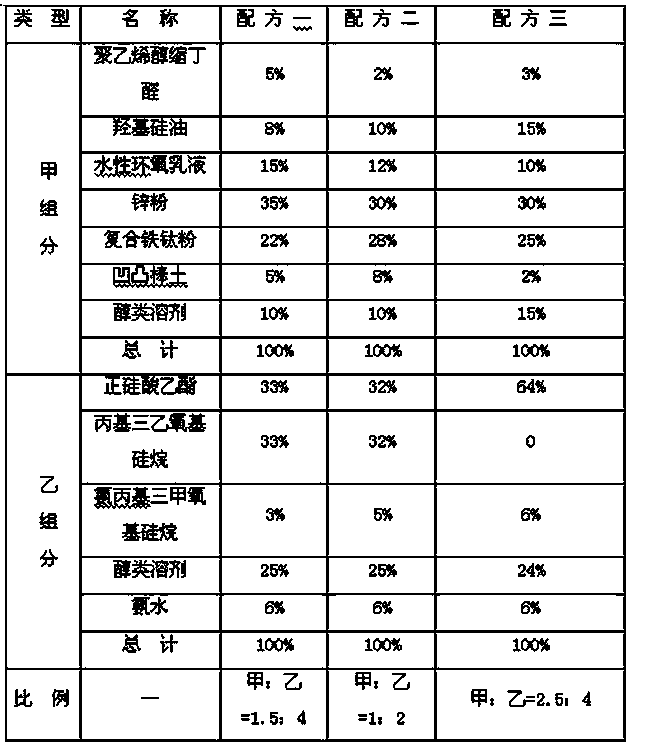

[0078] Embodiment two (alkaline preparation method):

[0079] The following components are proportioned according to weight percentage and mixed uniformly according to certain conditions:

[0080] A component:

[0081] Polyvinyl butyral: 2-5%

[0082] Hydroxy silicone oil: 8-15%

[0083] Water-based epoxy emulsion: 10-15%

[0084] Zinc powder: 30-35%

[0085] Composite iron and titanium powder: 15-30%

[0086] Attapulgite: 2-8%

[0087] Alcohol solvent: 15-35%

[0088] The sum of the above parts is 100%.

[0089] B component:

[0091] Aminopropyltrimethoxysilane: 3-6%

[0092] Alcohol solvent: 25-40%

[0093] Water: 5-15%

[0094] Ammonia: 2-8%

[0095] The sum of the above parts is 100%.

[0096] A component: B component = 1.5-2.5 : 4

[0097] Described preparation method comprises the following steps:

[0098] (1) Preparation of component A: polyvinyl butyral: 2-5%, hydroxyl silicone oil: 8-15%, water-based epoxy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com