A kind of coking wastewater pyrolysis gas corrosion inhibitor and preparation method thereof

A technology for pyrolyzing coal gas and coking wastewater, which is applied in the field of iron and steel metallurgy and chemical industry, which can solve the problems of water consumption and flue gas heat loss, and achieve the effects of uniform corrosion protection, extended service life, and high comprehensive corrosion inhibition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

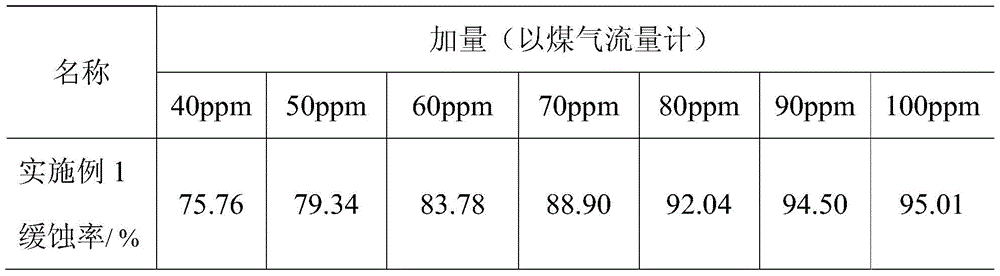

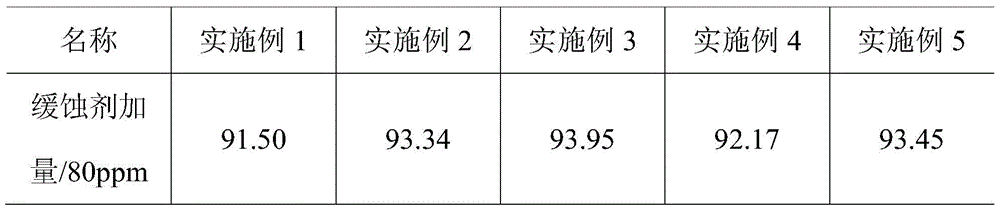

Examples

Embodiment 1

[0017] The pyrolysis gas corrosion inhibitor of coking wastewater in this example is made of 40% rosin imidazoline polyoxyethylene ether, 25% polyethylene oxide octadecylamine, and 35% pentane by mass fraction.

[0018] The specific preparation method of the coking wastewater pyrolysis gas corrosion inhibitor in this embodiment includes the following steps:

[0019] 1) Stirring and reacting rosin and diethylenetriamine at 210°C for 2h, then raising the temperature to 230°C under a vacuum condition of 2.96kPa, and keeping the temperature for 4h to obtain rosin imidazoline; among them, rosin and diethylenetriamine The molar ratio is 3:1;

[0020] 2) After mixing rosin imidazoline, boric acid and ethylene oxide, reflux reaction at 0.2 MPa and 60°C for 3 hours, so that rosin imidazoline and ethylene oxide undergo addition reaction to obtain rosin imidazoline polyoxyethylene ether; , the mol ratio of rosin imidazoline, catalyst and ethylene oxide is 3:0.5:1;

[0021] 3) Add rosin...

Embodiment 2

[0023] The pyrolysis gas corrosion inhibitor of coking wastewater in this embodiment is made of 40% rosin imidazoline polyoxyethylene ether, 30% isopropylamine, and 30% hexane by mass fraction.

[0024] The specific preparation method of the coking wastewater pyrolysis gas corrosion inhibitor in this embodiment includes the following steps:

[0025] 1) Stir and react rosin and diethylenetriamine at 220°C for 2h, then raise the temperature to 240°C under a vacuum condition of 4.33kPa, and keep the temperature for 4h to obtain rosin imidazoline; among them, rosin and diethylenetriamine The molar ratio is 3:1;

[0026] 2) After mixing rosin imidazoline, boric acid and ethylene oxide, reflux reaction at 0.3MPa and 60°C for 3 hours to obtain rosin imidazoline polyoxyethylene ether; wherein, the molar ratio of rosin imidazoline, boric acid and ethylene oxide is 3:0.5:1;

[0027] 3) Add rosin imidazoline polyoxyethylene ether, isopropylamine and hexane into the container, then rais...

Embodiment 3

[0029] In this example, the coking wastewater pyrolysis gas corrosion inhibitor is prepared by mixing 35% rosin imidazoline polyoxyethylene ether, 30% cyclohexylamine, and 35% hexane and octane at a volume ratio of 3:1 by mass fraction. made of mixed solvents.

[0030] The specific preparation method of the coking wastewater pyrolysis gas corrosion inhibitor in this embodiment includes the following steps:

[0031] 1) Stir and react rosin and diethylenetriamine at 210°C for 2h, then raise the temperature to 230°C under a vacuum condition of 3.78Pa, and keep the temperature for 4h to obtain rosin imidazoline; among them, rosin and diethylenetriamine The molar ratio is 3:1;

[0032] 2) After mixing rosin imidazoline, boric acid and ethylene oxide, reflux reaction at 0.3MPa and 60°C for 3 hours to obtain rosin imidazoline polyoxyethylene ether; wherein, the molar ratio of rosin imidazoline, boric acid and ethylene oxide is 3:0.5:1;

[0033] 3) Add rosin imidazoline polyoxyethy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com