A kind of preparation method of ceramic coating diaphragm

A technology of ceramic coating and diaphragm, which is applied in the direction of electrical components, circuits, battery pack parts, etc., can solve the problems of low bonding strength and uneven ceramic coating, and achieve improved thermal shrinkage performance, improved wettability, Effect of improving battery life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

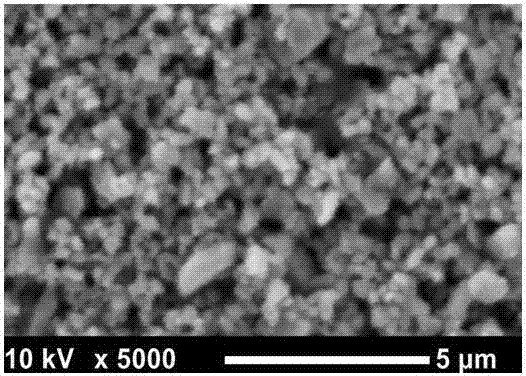

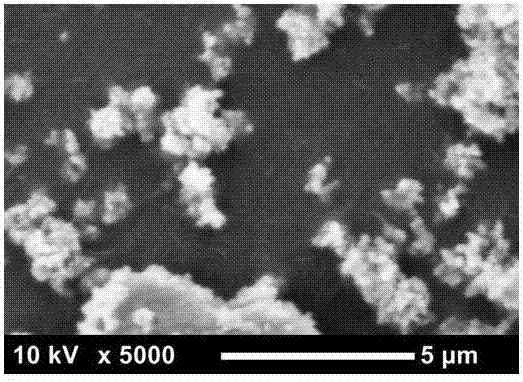

Image

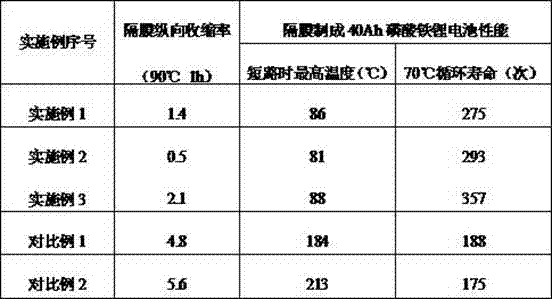

Examples

Embodiment 1

[0030] (1) Preparation of ceramic slurry

[0031] ①Add deionized water and 0.2μm silica, ceramic powder and deionized water to the vacuum, high-speed, planetary stirring equipment with ultrasonic oscillation function (speed 0~3000r / min adjustable, ultrasonic frequency 20kHz oscillation) The weight ratio of water is 30: 70, 3000r / min high-speed stirring and ultrasonic vibration for 0.5 hours;

[0032] ② Add sodium polyacrylate with 5% slurry amount, stir at 3000r / min at high speed while ultrasonic vibration for 0.5 hours;

[0033] ③ Add 0.5% glycerin of slurry amount, stir at 3000r / min at high speed while ultrasonic vibration for 2 hours;

[0034] ④ Add 10% carboxyl styrene butadiene rubber (SBR) (prepared to 50% emulsion), and add 5% sodium carboxymethyl cellulose (CMC) (prepared to 2% solution) ; 3000r / min high-speed stirring while ultrasonic vibration for 2 hours;

[0035] ⑤ Reduce the speed to 500 r / min, turn off the ultrasonic vibration, turn on the vacuum, stir for 0.5 hours, the...

Embodiment 2

[0042] (1) Preparation of ceramic slurry

[0043] ①Add deionized water, silicon oxide with a particle size of 0.8μm and zirconia with a particle size of 1.0 to the vacuum, high-speed, planetary stirring equipment with ultrasonic oscillation function (speed 0~3000r / min adjustable, ultrasonic frequency 20kHz oscillation) , Zinc oxide with a particle size of 0.4 (weight ratio is 7:2.5:0.5), the weight ratio of ceramic powder (silica, zirconia, zinc oxide mixture) and deionized water is 10: 90, 2000r / min high-speed stirring and ultrasonic Shake for 1 hour;

[0044] ② Add 0.5% of the slurry amount of sodium orthophosphate, sodium silicate, sodium lauryl sulfate (weight ratio 1:1:1), 2000r / min high-speed stirring and ultrasonic vibration for 1 hour;

[0045] ③ Add 10% of N-methylpyrrolidone, alcohol, and propylene carbonate (weight ratio 1:1:1) with a slurry amount of 10%, stirring at a high speed of 2000r / min and ultrasonic vibration for 1 hour;

[0046] ④ Add LA133 glue with 6% slurry vo...

Embodiment 3

[0054] (1) Preparation of ceramic slurry

[0055] ①Add deionized water and aluminum oxide with a particle size of 0.4μm and a particle size of 0.05 to the vacuum, high-speed, planetary stirring equipment with ultrasonic oscillation function (speed 0~3000r / min adjustable, ultrasonic frequency 20kHz oscillation) Magnesium oxide (weight ratio 9:1), the weight ratio of ceramic powder (a mixture of aluminum oxide and magnesium oxide) and deionized water is 5:95, 1500r / min high-speed stirring and ultrasonic vibration for 2 hours;

[0056] ② Add 3% of the slurry amount of sodium polymetaphosphate and ammonia (weight ratio 3:1), 1500r / min high-speed stirring and ultrasonic vibration for 2 hours;

[0057] ③ Add 5% dimethyl sulfoxide, polyoxyethylene alkyl phenol ether, polyoxyethylene fatty alcohol ether, polyvinyl alcohol (weight ratio 1:1:1:0.5) with 5% slurry amount, and stir at 1500r / min at high speed Ultrasonic vibration for 2 hours;

[0058] ④ Add LA134 glue with 1% slurry volume; 1500r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com