Catalytic ozonation catalyst for volatile organic waste gas treatment as well as preparation method and application of catalytic ozonation catalyst

A volatile organic and ozone oxidation technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve harsh reaction conditions, high investment and operating costs, The problem of low pollutant efficiency, etc., can reduce the reaction temperature, improve the service life, and achieve the effect of high catalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

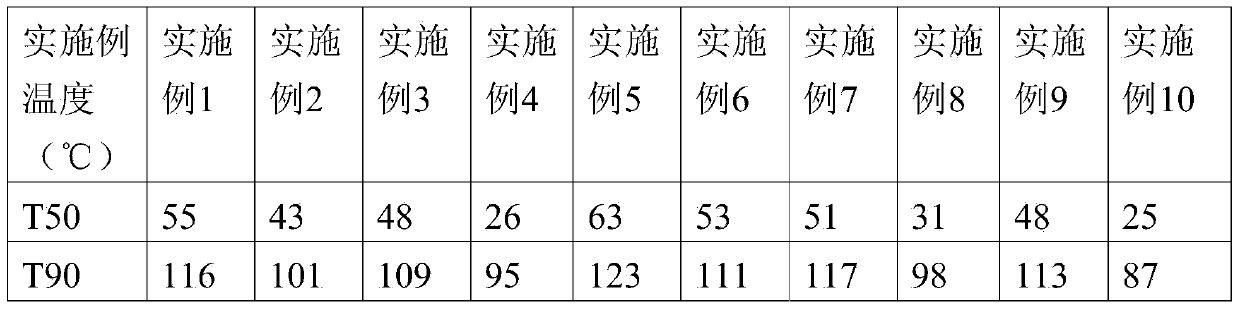

Examples

Embodiment 1

[0042] (1) Weigh 0.867 grams of Fe(NO 3 )3 9H 2 O, 1.092 grams of 50wt% Mn(NO 3 ) 2 Aqueous solution, add 100ml deionized water to make a solution. Then magnetically stir at constant temperature at 60°C for 20-30min until the solute is completely dissolved to prepare the impregnating solution of the active component.

[0043] (2) Weigh 2 grams of γ-alumina balls with a particle size of about 3.0 mm, wash them with deionized water for 3 times, and then immerse them in the active component impregnation solution, and then transfer all the impregnation solutions and carriers to the Erlenmeyer flask In this process, the water in the solution was completely evaporated to dryness at 80°C, then dried at 110°C for 10 hours, and then calcined at 600°C for 6 hours to obtain Fe with a metal element loading of 12%. 0.5 -Mn 0.5 / γ-Al 2 o 3 catalyst.

Embodiment 2

[0045] (1) Weigh 0.289 grams of Fe(NO 3 ) 3 9H 2 O, 1.820 grams of 50wt% Mn (NO 3 ) 2 Aqueous solution, add 100ml deionized water to make a solution. Then magnetically stir at constant temperature at 60°C for 20-30min until the solute is completely dissolved to prepare the impregnating solution of the active component.

[0046] (2) Weigh 2 grams of γ-alumina balls with a particle size of about 3.0 mm, wash them with deionized water for 3 times, and then immerse them in the active component impregnation solution, and then transfer all the impregnation solutions and carriers to the Erlenmeyer flask In this process, the water in the solution was completely evaporated to dryness at 80°C, then dried at 110°C for 10 hours, and then calcined at 600°C for 6 hours to obtain Fe with a metal element loading of 12%. 0.17 -Mn 0.83 / γ-Al 2 o 3 catalyst.

Embodiment 3

[0048] (1) Weigh 0.594 grams of Ni (NO 3 ) 2 ·6H 2 O, 1.092 grams of 50wt% Mn(NO 3 ) 2 Aqueous solution, add 100ml deionized water to make a solution. Then magnetically stir at constant temperature at 60°C for 20-30min until the solute is completely dissolved to prepare the impregnating solution of the active component.

[0049] (2) Weigh 2 grams of γ-alumina balls with a particle size of about 3.0 mm, wash them with deionized water for 3 times, and then immerse them in the active component impregnation solution, and then transfer all the impregnation solutions and carriers to the Erlenmeyer flask In this method, the water in the solution was completely evaporated to dryness at 80°C, then dried at 110°C for 10 hours, and then calcined at 600°C for 6 hours to prepare Ni with a metal element loading of 12%. 0.5 -Mn 0.5 / γ-Al 2 o 3 catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com