Clubbed phosphor-doped mesoporous carbon as well as preparation method and application thereof

A mesoporous carbon and phosphorus doping technology, applied in the direction of hybrid capacitor electrodes, etc., can solve the problems of supercapacitor performance research, no special morphology, etc., and achieve good electrochemical performance, easy control, and good thermal stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

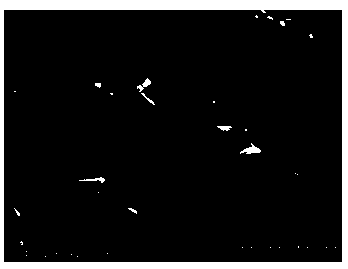

[0048] A method for preparing a rod-shaped phosphorus-doped mesoporous carbon material, specifically comprising the steps of:

[0049] (1) Dissolve 0.11g of phosphorus-containing precursor in 20g of ethanol, add 1.0g of rod-shaped mesoporous silica, and then add 1.13g of organic polymer, stir to make it fully mixed, and then place it Drying at 40°C for 24 hours at room temperature until ethanol is completely volatilized to obtain a carbon source / phosphorus source / silicon dioxide composite;

[0050] The amount of rod-shaped mesoporous silica, organic polymer, phosphorus-containing precursor and ethanol used above is according to the mass ratio of rod-shaped mesoporous silica: organic polymer: phosphorus-containing precursor: ethanol Calculated for the ratio of 1:1.13:0.11:20;

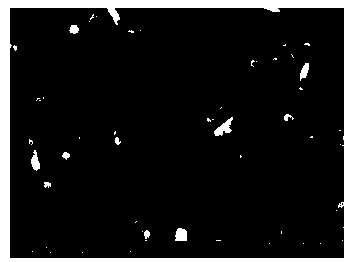

[0051] The pore volume of the rod-shaped mesoporous silica is 1.0-1.5 cm 3 / g, the long axis is 2.80 μm, the short axis is about 0.55 μm, and the axial ratio is 5.1;

[0052] Described organic macromo...

Embodiment 2

[0065] A method for preparing a rod-shaped phosphorus-doped mesoporous carbon material, specifically comprising the steps of:

[0066] (1) Dissolve 0.33g of phosphorus-containing precursor in 20g of ethanol, then add 1.0g of rod-shaped mesoporous silica, then add 1.11g of organic polymer and stir to make the organic polymer and The phosphorus-containing precursor is fully immersed in the pores of the rod-shaped mesoporous silica, and then placed at room temperature until the ethanol solvent evaporates, and then dried at 60°C for 24 hours to obtain a carbon source / phosphorus source / silicon dioxide composite thing;

[0067] The amount of rod-shaped mesoporous silica, organic polymer, phosphorus-containing precursor and ethanol used above is based on the mass ratio of rod-shaped mesoporous silica: organic polymer: phosphorus-containing precursor: ethanol Calculated for the ratio of 1:1.11:0.33:20;

[0068] The pore volume of the rod-shaped mesoporous silica is 1.0-1.5 cm 3 / g,...

Embodiment 3

[0077] A method for preparing a rod-shaped phosphorus-doped mesoporous carbon material, specifically comprising the steps of:

[0078] (1) Dissolve 0.58g of phosphorus-containing precursor in 20g of ethanol, add 1.0g of rod-shaped mesoporous silica, and then add 1.16g of organic polymer, stir to make the organic polymer and phosphorus-containing The precursor is fully immersed in the pores of rod-shaped mesoporous silica, and then placed at room temperature until ethanol is completely volatilized, and then dried at 80°C for 24 hours to obtain a phosphorus source / carbon source / silicon dioxide composite;

[0079] The amount of rod-shaped mesoporous silica, organic polymer, phosphorus-containing precursor and ethanol used above, according to the mass ratio of rod-shaped mesoporous silica: organic polymer: phosphorus-containing precursor: ethanol is 1:1.16:0.58:20 ratio calculation;

[0080] The pore volume of the rod-shaped mesoporous silica is 1.0-1.5 cm 3 / g, the long axis is...

PUM

| Property | Measurement | Unit |

|---|---|---|

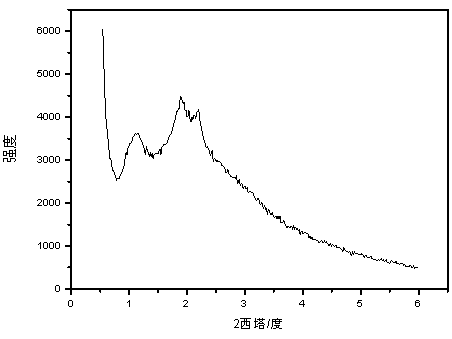

| pore size distribution | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com