Device for preparing magnesium oxide by saturated brine spray pyrolysis

A technology of spray pyrolysis and magnesium oxide, applied in magnesium oxide and other directions, can solve the problems of producing a large amount of carbon dioxide, complicated process and equipment, and high impurity content in the product, and achieve the effect of improving combustion efficiency, increasing residence time and good product performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

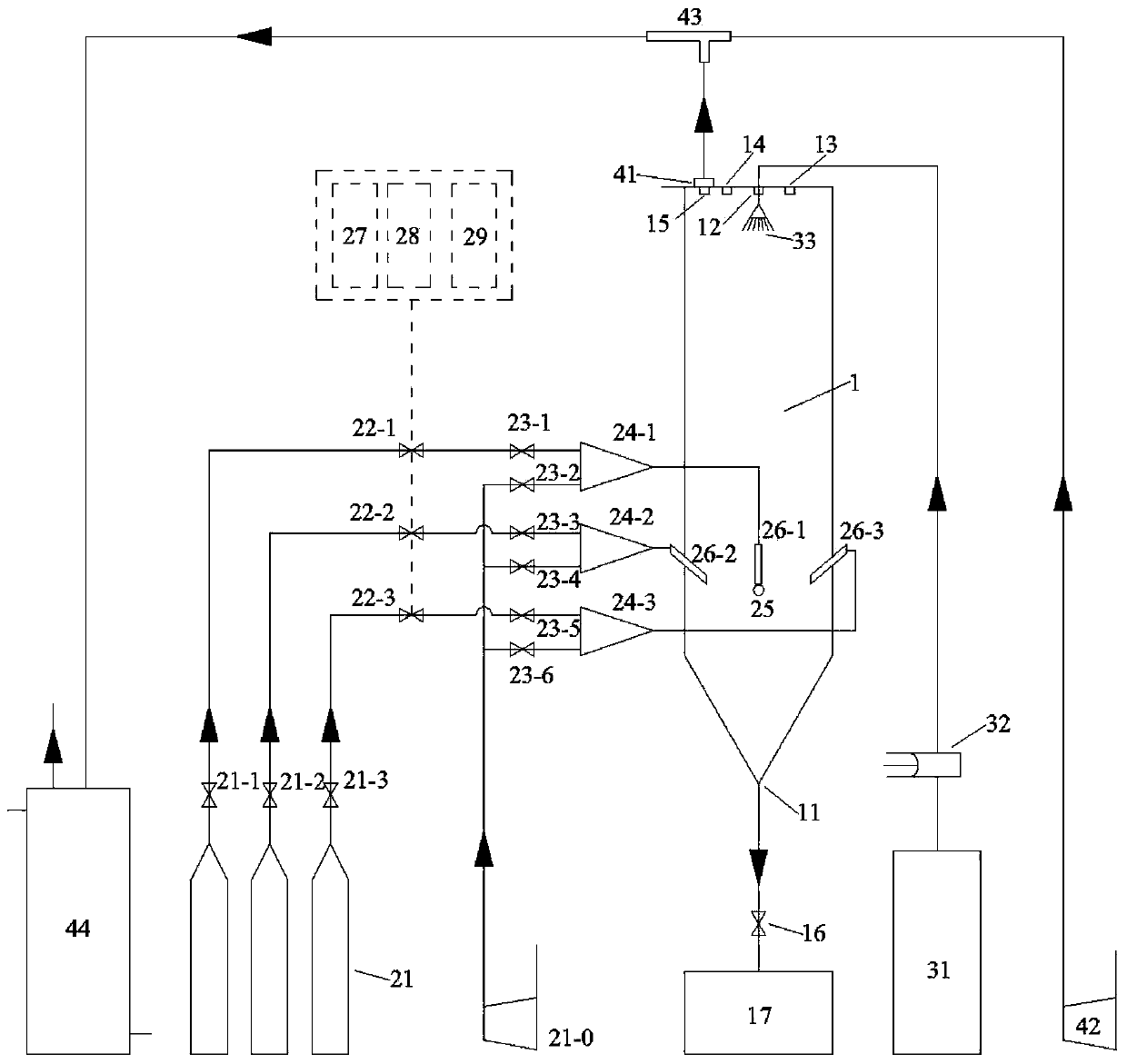

[0030] Such as figure 1 As shown, a device that can quickly pyrolyze brine to produce magnesium oxide mainly includes a pyrolysis furnace 1, a hot air system, a feeding system, and a tail gas treatment system.

[0031] There is a discharge port 11 at the bottom of the pyrolysis furnace 1, and four openings at the top, which are: feed port 12, temperature control instrument detection port 13, temperature measurement port 14, and gas outlet 15. There are three combustion gun inlets inside The first combustion gun 26-1, the second combustion gun 26-2, the third combustion gun 26-3 and the flame detector 25; the discharge port 11 is connected with the product bin 17 through the valve 16, and the feed port is installed at 12 places A liquid atomizing nozzle 33 is installed, the nozzle 33 is connected with the feed pump 32, and then connected with the raw material storage tank 31; the temperature control instrument detection port 13 and the temperature measurement port 14 are equipp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com