Method for preparing high-purity manganese sulfate through extracting low-grade pyrolusite by using rice straw

A technology of pyrolusite and straw straw, which is applied in the field of hydrometallurgy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

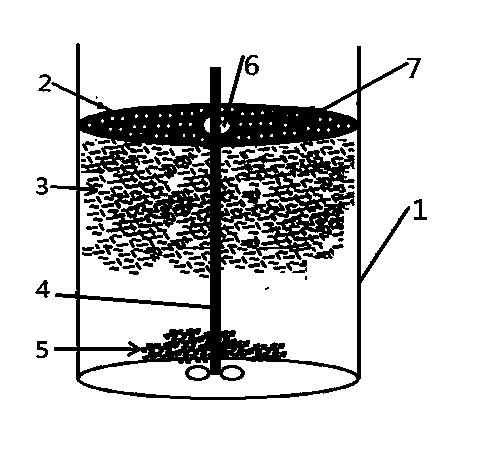

[0022] (1) Add 10g of pyrolusite (see Table 1 for its indicators) into the reaction vessel, then add 3 M sulfuric acid solution with a volume of 180ml, and then add 20g of crushed dry straw (length after crushing 2 to 4 mm). Since the crushed dry straw has a low density and cannot sink into the sulfuric acid solution, the reaction is carried out in a special straw leaching reaction device for pyrolusite. Such as figure 1 As shown, the reaction device has a cylindrical reaction vessel 1 with an upper opening. A gland 2 is arranged at the opening of the reaction vessel. There are many small holes 7 on the gland 2. There is a central hole 6 in the middle of the gland 2. The agitator 4 passes through the The central hole 6 protrudes into the reaction vessel. The diameter of gland 2 is slightly smaller than the internal diameter of reaction vessel, and gland 2 can all be pressed in the sulfuric acid with dry straw stalk 3;

[0023] (2) Turn on the stirrer and heat the solution ...

Embodiment 2

[0032] (1) Add 20g of pyrolusite into the reaction vessel, then add 3 M sulfuric acid solution with a volume of 320ml, and then add 35g of pulverized dry straw (length after pulverization is 2-4 mm). The reaction was carried out in the reaction device for leaching pyrolusite with straw straw as provided in the examples.

[0033] (2) Turn on the stirring device and heat the solution to 80 0 C, the reaction was continuously stirred at this temperature for 12 hours. After the reaction is completed, cool to room temperature, first remove the straw stalks on the surface, filter, then filter the remaining solution, wash the filter residue with water for 3 times, and combine the two filtrates. The leaching rate is greater than 97.1%.

[0034] (3) Use 10% ammonia solution to adjust the pH of the above-mentioned pyrolusite leachate to 5-6, so that the ferric iron is precipitated as ferric hydroxide; then add barium sulfide under constant stirring to make the Ni in the pyrolusite leac...

Embodiment 3

[0038] (1) Add 30g of pyrolusite into the reaction vessel, then add 3 M sulfuric acid solution with a volume of 450ml, and then add 50g of crushed dry straw (length after crushing is 2-4 mm). The reaction was carried out in the reaction device for leaching pyrolusite with straw straw as provided in the examples.

[0039] (2) Turn on the stirring device and heat the solution to 95 0 C, continuously stirring the reaction at this temperature for 15 hours. After the reaction is completed, cool to room temperature, first remove the straw stalks on the surface, filter, then filter the remaining solution, wash the filter residue with water for 3 times, and combine the two filtrates. The leaching rate is greater than 96.4%.

[0040] (3) Use 10% ammonia solution to adjust the pH of the above-mentioned pyrolusite leachate to 5-6, so that the ferric iron is precipitated as ferric hydroxide; then add barium sulfide under constant stirring to make the Ni in the pyrolusite leachate 2+ 、C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com