Carbon-coated Li3VO4 lithium ion battery anode material and preparation method thereof

A lithium-ion battery and negative electrode material technology, applied in battery electrodes, secondary batteries, circuits, etc., to achieve the effects of simple synthesis process, high charge and discharge capacity, and excellent cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

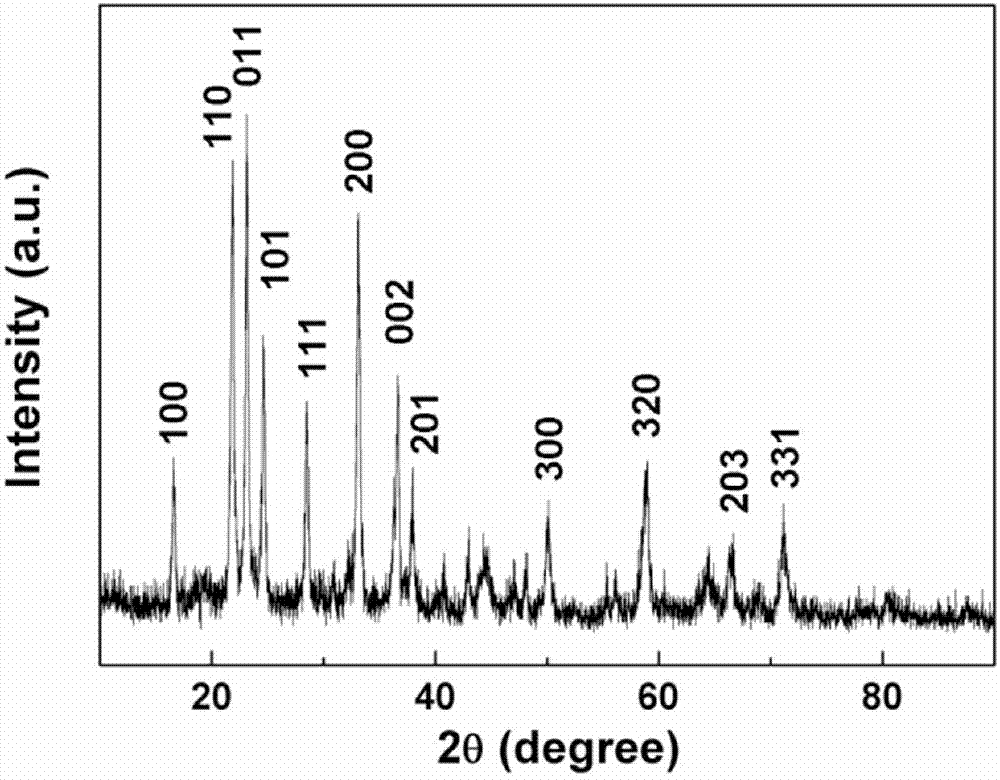

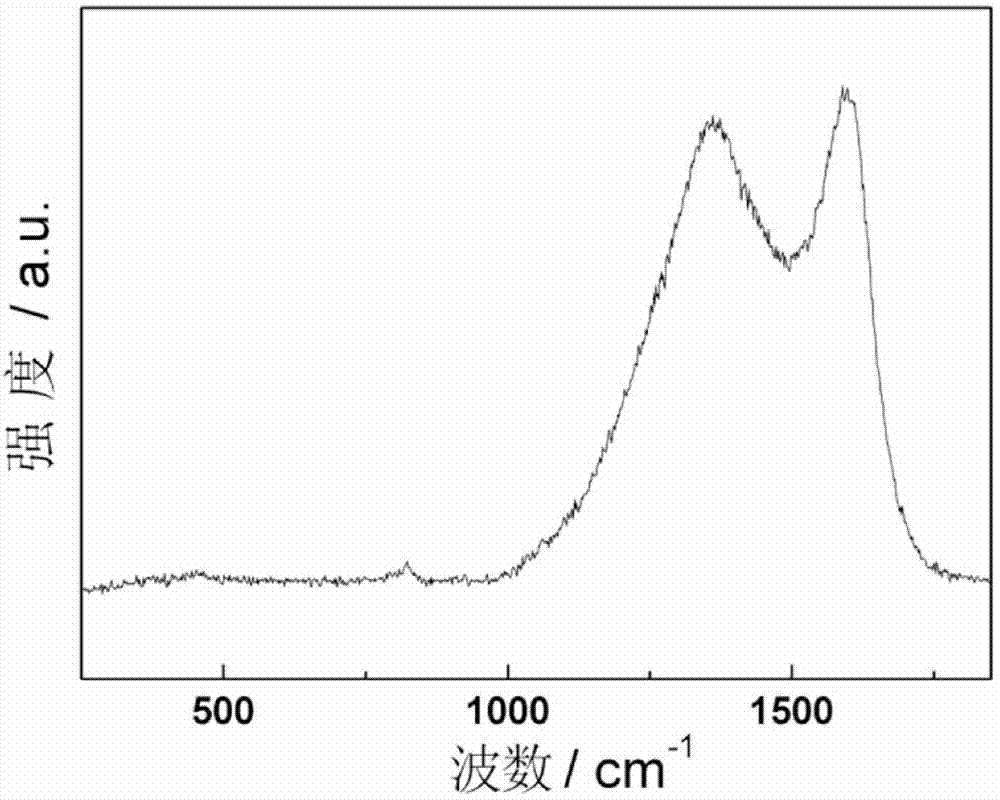

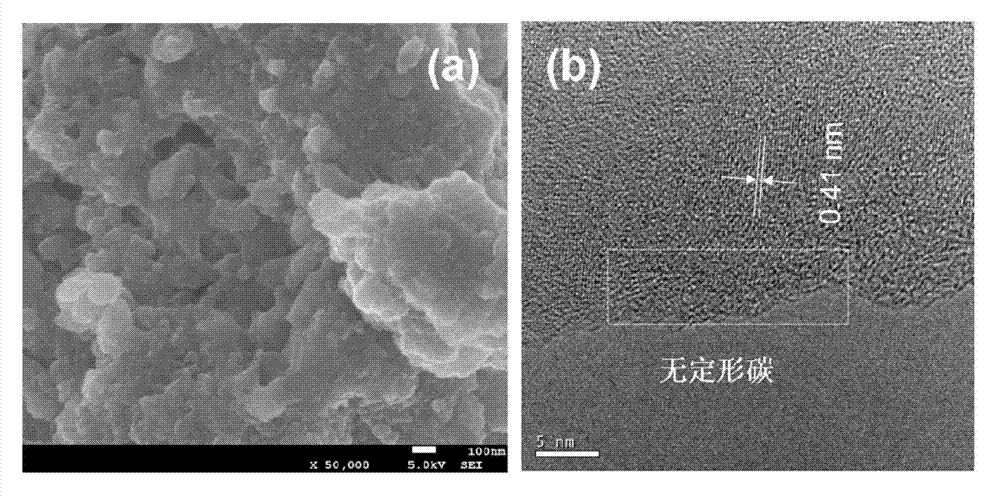

[0018] Weigh 1mmol of vanadium pentoxide, 3mmol of lithium carbonate and 5mmol of hexamethylenetetramine into a beaker, add an appropriate amount of distilled water and stir evenly, transfer to a hydrothermal ax to react at 140°C for 24 hours, transfer the resulting solution to the beaker and Add 0.05mmol citric acid, stir well and dry. Place the dried product in a crucible, move the crucible into a high-temperature tube furnace, calcinate at 550°C for 5 hours under nitrogen, and cool naturally to obtain carbon-coated Li 3 VO 4 sample. The results show that the prepared sample is located at 16.3 through XRD pattern analysis o , 21.6 o , 22.9 o , 24.4 o , 28.2 o , 32.8 o , 36.3 o , 37.6 o , 49.8 o , 58.7 o , 66.2 o and 70.9 o The diffraction peaks at correspond to the orthorhombic Li 3 VO 4 (100), (110), (011), (101), (111), (200), (002), (201), (202), (320) of (XRD card JCPDS, No. 38-1247) ), (203) and (322) crystal planes. The prepared sample was analyzed ...

Embodiment 2

[0020] Weigh 1mmol of vanadium pentoxide, 3mmol of lithium carbonate and 5mmol of hexamethylenetetramine into a beaker, add an appropriate amount of distilled water and stir evenly, transfer to a hydrothermal ax to react at 140°C for 24 hours, transfer the resulting solution to the beaker and Add 0.05mmol citric acid, stir well and dry. Place the dried product in a crucible, move the crucible into a high-temperature tube furnace, calcinate at 500°C for 5 hours under nitrogen, and cool naturally to obtain carbon-coated Li 3 VO 4 sample. The results show that the as-prepared carbon coated Li 3 VO 4 Nanoparticles used as lithium-ion battery anode materials show that the first charge and discharge capacities are 355 and 445 mAh / g, and after 100 cycles, the charge and discharge capacities are both 419 and 420 mAh / g, showing a higher specific capacity and better Cycle stability.

Embodiment 3

[0022] Weigh and weigh 1mmol of vanadium pentoxide, 3mmol of lithium carbonate and 5mmol of hexamethylenetetramine into a beaker, add an appropriate amount of distilled water and stir evenly, transfer to a hydrothermal ax to react at 140°C for 24 hours, and transfer the resulting solution to the beaker And add 0.05mmol citric acid, fully stir and dry. Place the dried product in a crucible, move the crucible into a high-temperature tube furnace, calcinate at 600°C for 5 hours under nitrogen, and cool naturally to obtain carbon-coated Li 3 VO 4 sample. The results show that the as-prepared carbon coated Li 3 VO 4 Nanoparticles as lithium-ion battery anode materials show the first charge and discharge capacities of 494 and 620 mAh / g, and after 100 cycles, the charge and discharge capacities are both 496 and 498 mAh / g, showing high specific capacity and excellent cycle stable performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com