Microbial fertilizer granule, microbial fertilizer granule carrier and preparation method of microbial fertilizer granule

A technology of microbial fertilizers and granules, applied in fertilizer forms, fertilizer mixtures, fertilization devices, etc., can solve problems such as unstable colonization, and achieve the effect of prolonging the maintenance of integrity, prolonging the time of maintaining integrity, and improving soil nutrients.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

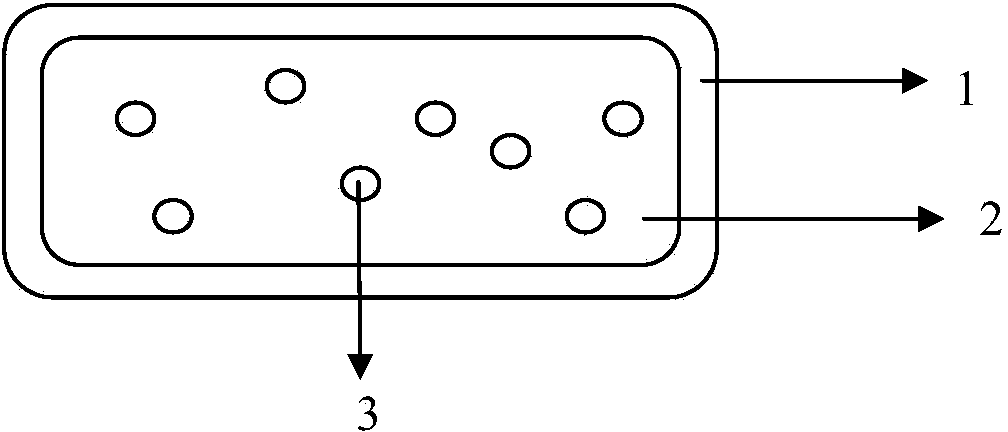

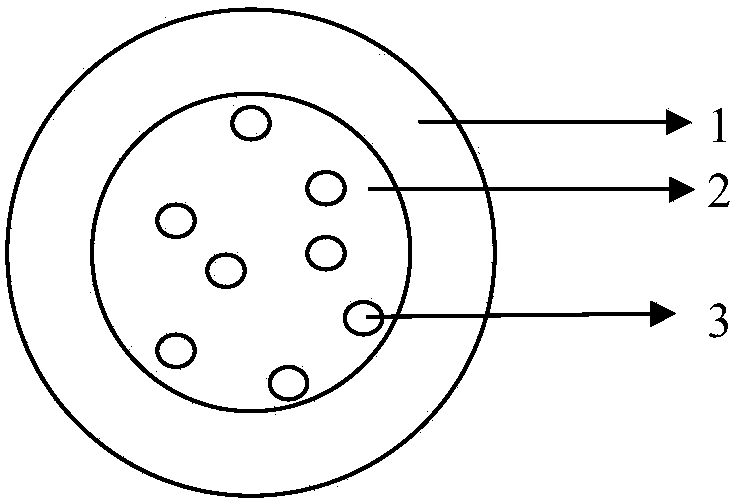

[0053] Embodiment 1: the basic support component and content of microbial fertilizer:

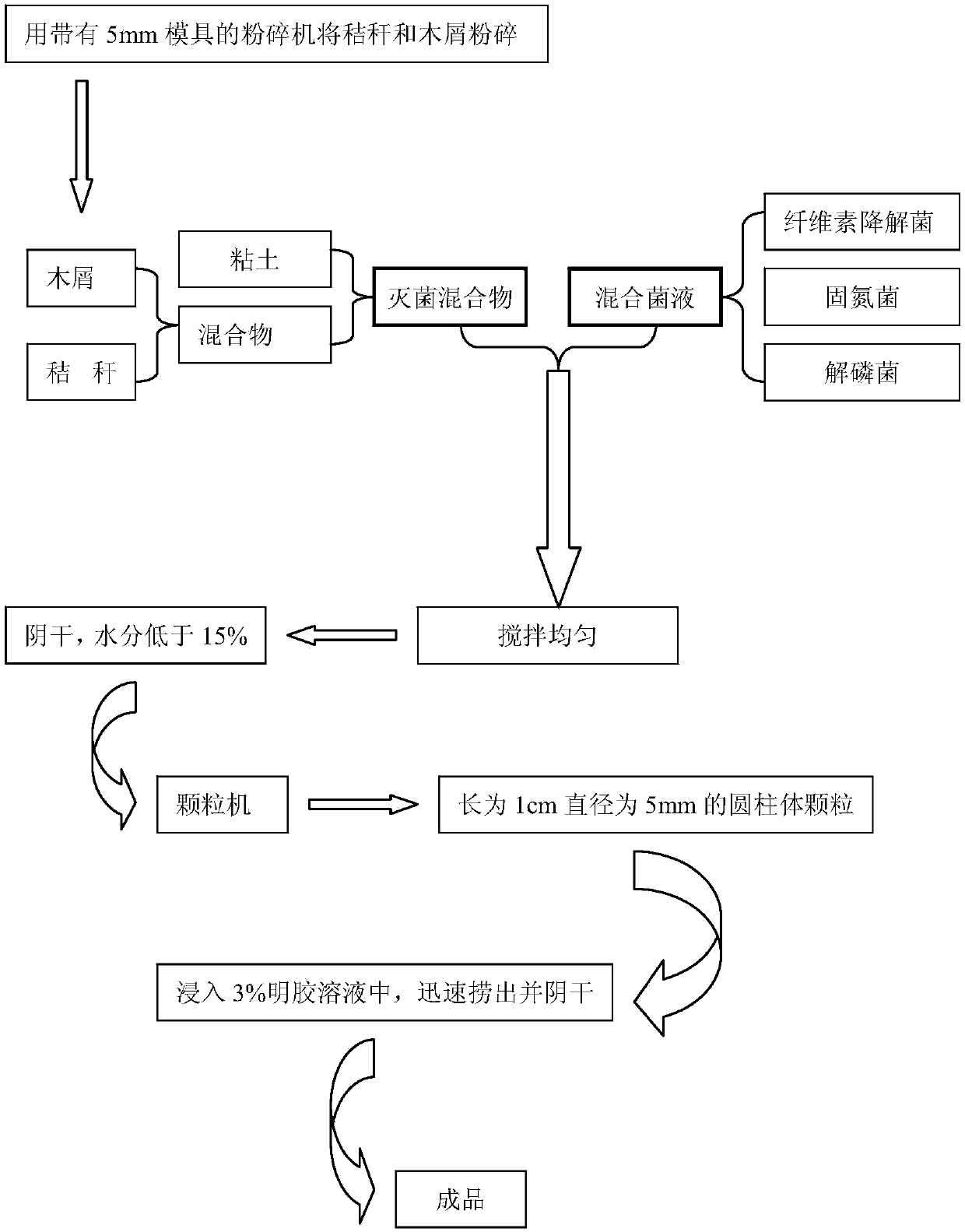

[0054] Crop stalks and sawdust were pulverized with a multifunctional pulverizer with a 5mm mould. Mix the two by mass 1:1, and add clay after mixing evenly. The clay described in the present invention may be any soil other than sandy soil, which acts to bind the mixture. The optimized experimental data of adding clay ratio is shown in Table 1:

[0055] Table 1: The cellulose content of the basic support of microbial fertilizer granules under different ratios

[0056]

[0057] Wherein, when the cellulose ratio reaches 50%, the microbial fertilizer particles can be bonded optimally while the cellulose addition ratio reaches the maximum value.

[0058] Subsequently, the ratio between straw and sawdust was further adjusted, and the results showed that the ratio between straw and sawdust can be selected in a wide range, and the specific ratio will not significantly affect the support mixt...

Embodiment 2

[0061] Embodiment 2: Bacteria antagonism experiment in the microbial fertilizer granule

[0062] In actual application, microbial fertilizer particles are small and closed. In order to determine whether multiple strains in the particles can coexist for a long time, it is necessary to conduct antagonism experiments between different strains. Those that do not produce antagonists with other added strains can be applied in microbial fertilizers.

[0063] The experimental method is that an activated logarithmic growth phase strain absorbs 200ul of bacterial liquid and evenly spreads it on ordinary 1 / 2R 2 A: on solid medium; then draw 2 ul of the second logarithmic growth phase strain and drop it on the above-mentioned coated medium (several spots can be dropped according to the size of the petri dish); culture for 5-7 days. Observe whether there is a zone of inhibition near the bacterial droplet of the second bacterial strain. If no zone of inhibition is produced, it is prelimina...

Embodiment 3

[0065] Embodiment 3: detection of the co-growth status of mixed bacterial strains

[0066] The different bacterial strains to be added to the granules were cultured in liquid medium, and when the OD value of the bacterial liquid was between 0.6 and 0.8, the different cultured bacterial strains were added to the new medium in equal amounts for cultivation. Samples were collected on the 1st, 3rd, 5th, 7th, and 10th day of culture, and denaturing gradient gel electrophoresis (DGGE) was performed to analyze the growth status of different strains under mixed culture conditions. Experiments have proved that different strains can grow and reproduce well under the condition of mixed culture.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com