Household biomass pyrolysis charcoal gas co-combustion method and stove

A biomass pyrolysis and char gas technology, which is applied in the fields of biofuels, household stoves/stoves, heating fuels, etc. health and other issues, to achieve the effect of reducing the trouble of collection, widening the adaptability of biomass raw materials, and eliminating smoke and dust efflux pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

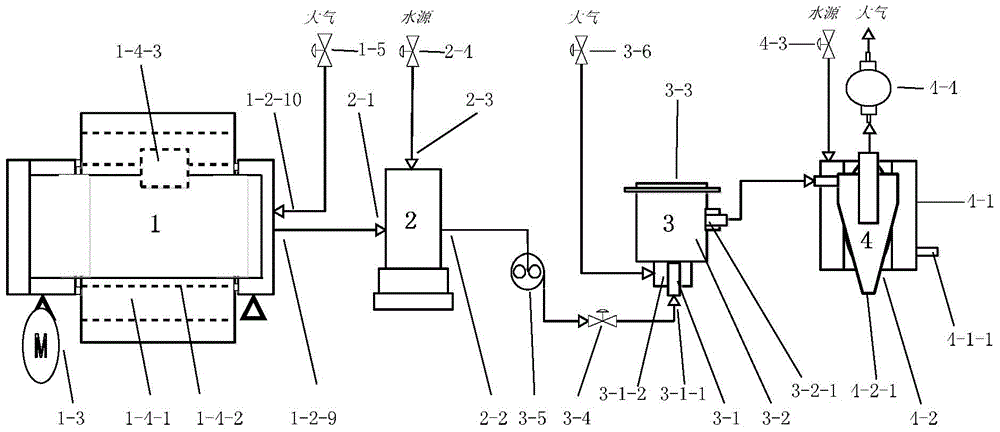

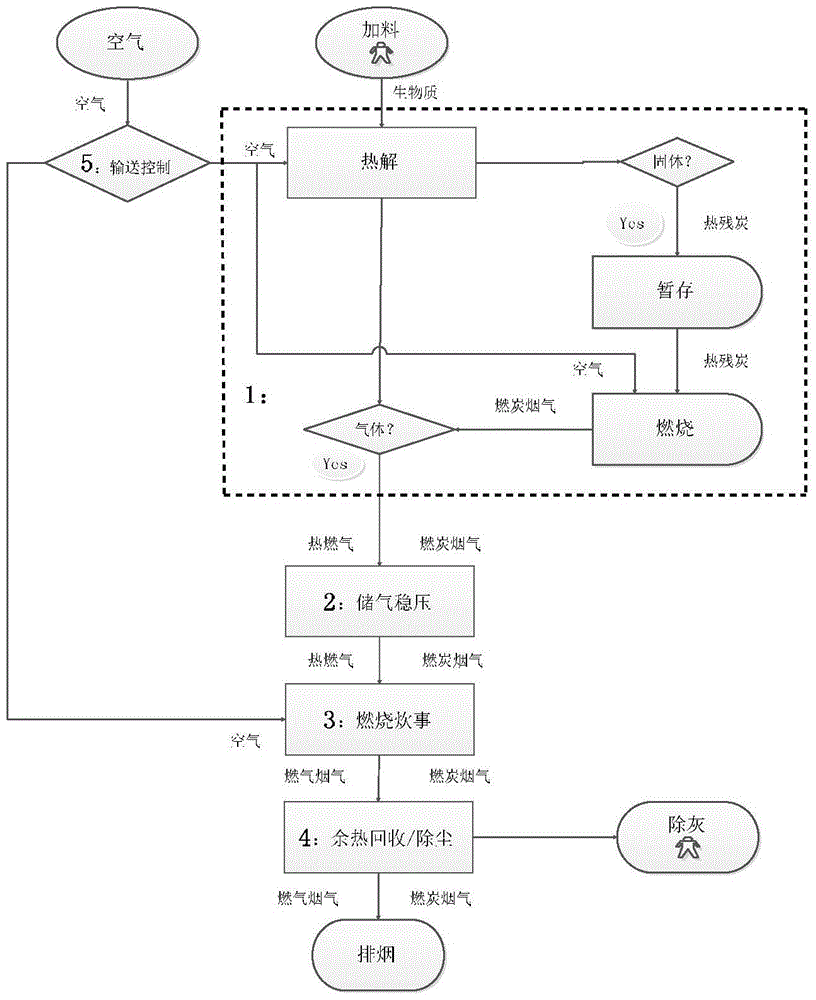

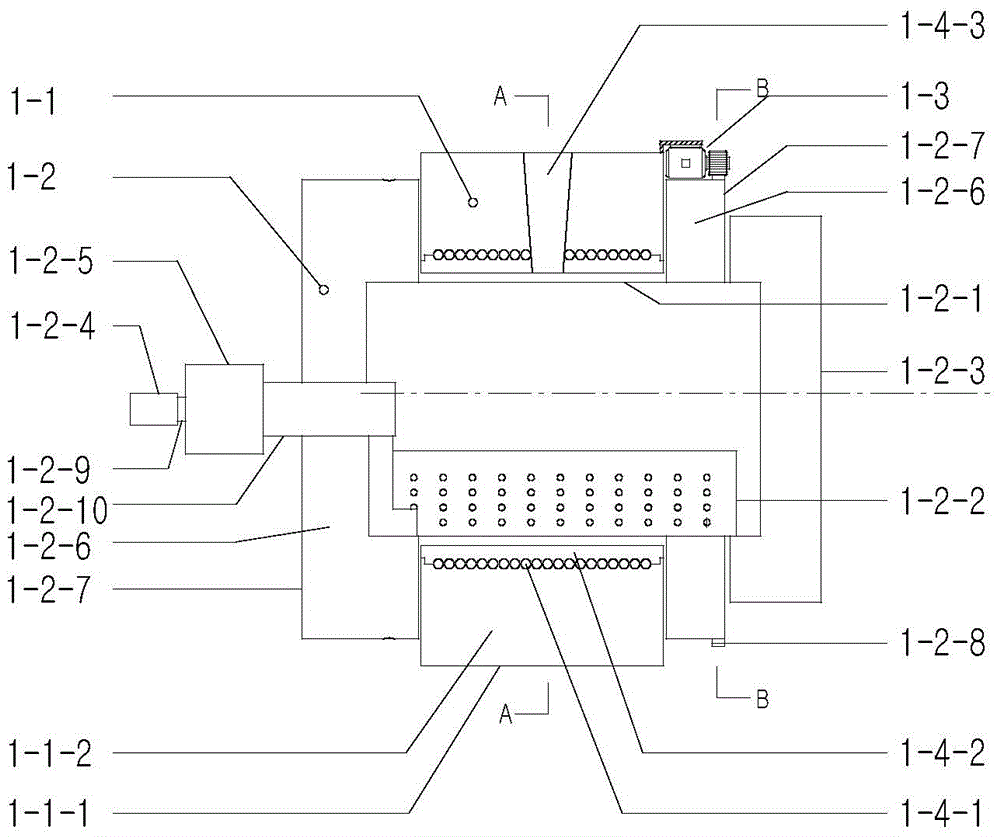

[0040] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings. In the figure: rotating drum type pyrolysis reactor 1, stator 1-1, stator shell 1-1-1, stator insulation layer 1-1-2, rotor 1-2, rotor inner shell 1-2-1, rotor inner Baffle plate 1-2-2, rotor cap 1-2-3, rotary gas connector 1-2-4, rotary air connector 1-2-5, rotor insulation layer 1-2-6, rotor shell 1-2- 7. Rotor gear 1-2-8, rotor gas outlet 1-2-9, rotor air inlet 1-2-10, drive motor 1-3, electric heating layer 1-4-1, electric heating radiation cavity 1-4-2 , Convergent sunlight irradiation cavity 1-4-3, air valve 1-5, gas cabinet 2, gas cabinet gas inlet 2-1, gas cabinet gas outlet 2-2, gas cabinet water supply port 2-3, water supply valve 2-4 , water level gauge 2-5, gas stove 3, stove burner 3-1, stove burner gas inlet 3-1-1, stove burner air inlet 3-1-2, stove chamber 3-2, stove flue gas outlet 3 -...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com