Preparation method of conductive slow-release nerve tissue engineering scaffold

A nerve tissue, slow-release technology, which is applied in the preparation of conductive slow-release nerve tissue engineering scaffolds and the field of nerve defect repair, achieves the effects of good biocompatibility, few control parameters, and simple preparation device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

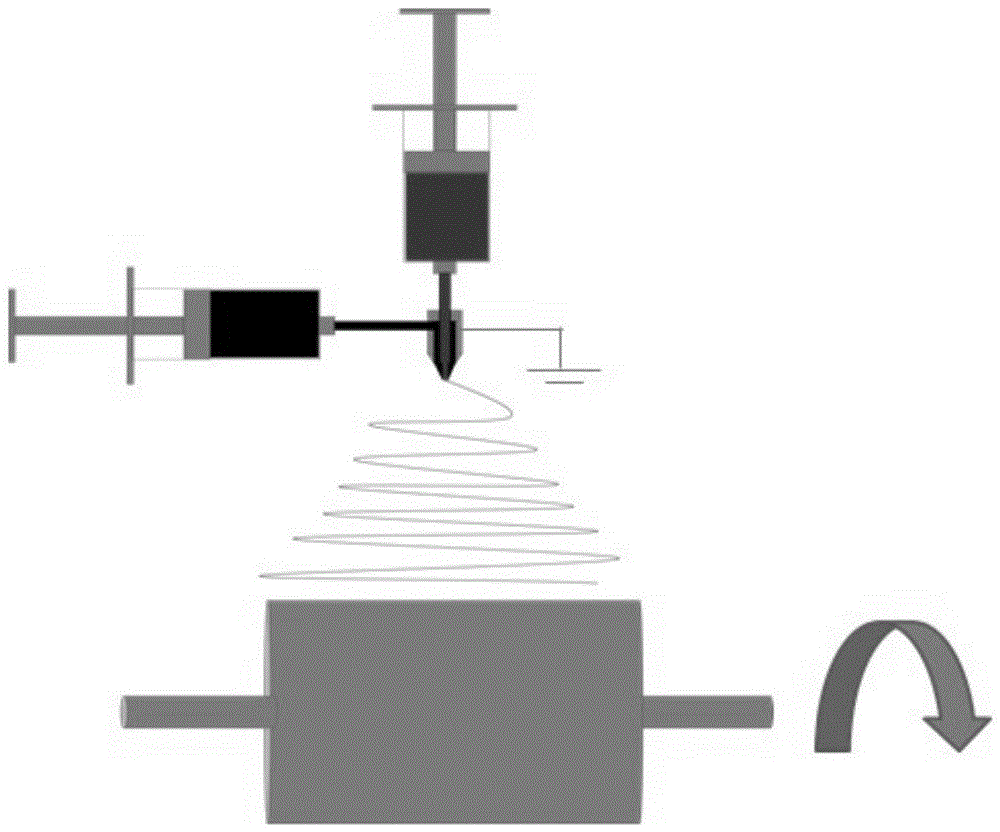

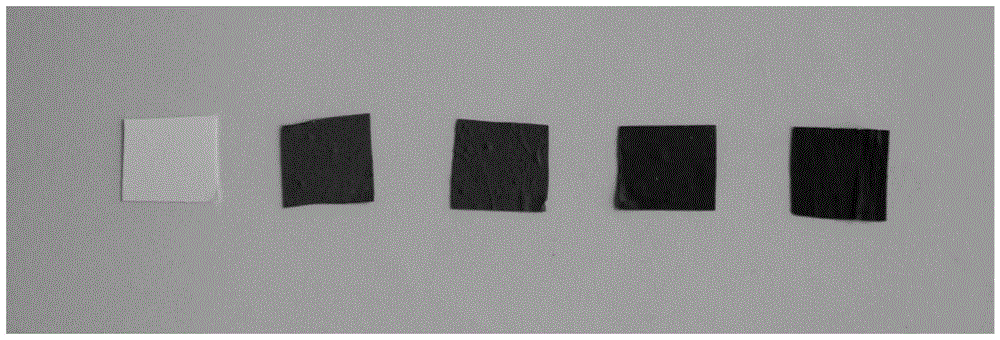

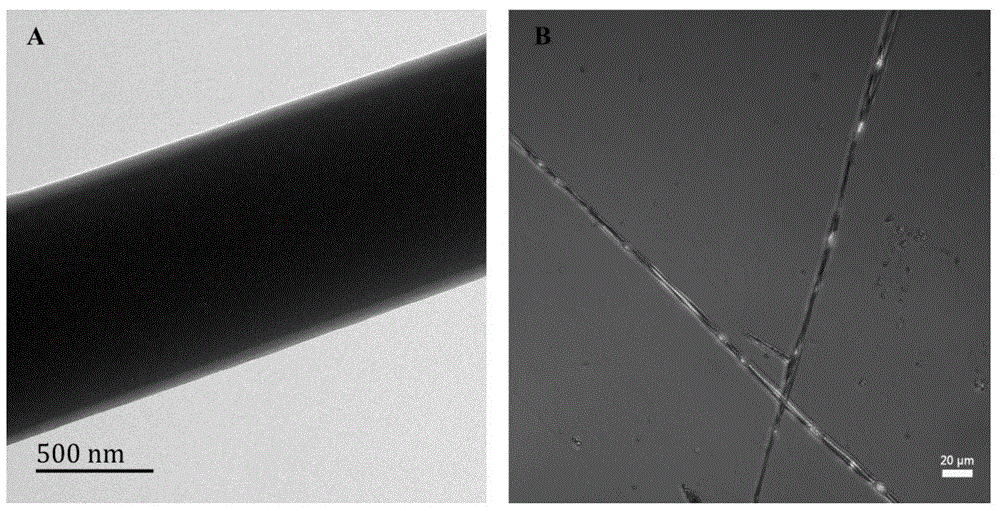

[0035] Weigh 0.1g of protein silk fibroin, 0.3g of lactic acid-caprolactone copolymer, dissolve in 5ml of hexafluoroisopropanol (HFIP), the molecular weight of lactic acid-caprolactone copolymer is Mw≈300,000, at 200r / min. Stir at a high speed for 5 hours and mix evenly to obtain a solution with a total concentration of 8% (w / v); after mixing evenly, add 60mg of polyaniline (Mn≈15,000) and camphorsulfonic acid, and then magnetically stir at a rate of 300r / min. After 48 hours, the cortex electrospinning solution was prepared by mixing evenly, and 1 ml of 10 μg / ml nerve growth factor (NGF) ultrapure aqueous solution was taken as the core electrospinning solution. The electrospinning solution of the shell layer was loaded into a syringe, and the advancing speed of the micro-injection pump was controlled to be 1ml / h. The electrospinning solution of the core layer was loaded into another syringe, and the advancing speed of the micro-injection pump was controlled to be 0.2ml / h. The ...

Embodiment 2

[0037]Weigh 0.125g of protein silk fibroin, 0.375g of lactic acid-caprolactone copolymer, dissolve in 5ml hexafluoroisopropanol (HFIP), the molecular weight of lactic acid-caprolactone copolymer is Mw≈300,000, at 200r / min. Stir at a high speed for 5 hours and mix evenly to obtain a solution with a total concentration of 10% (w / v); after mixing evenly, add 80 mg of polyaniline (Mn≈15,000) and camphorsulfonic acid, and then magnetically stir at a rate of 300r / min. After 48 hours, the cortex electrospinning solution was prepared by mixing evenly, and 1 ml of 10 μg / ml nerve growth factor (NGF) ultrapure aqueous solution was taken as the core electrospinning solution. The electrospinning solution of the shell layer was loaded into a syringe, and the advancing speed of the micro-injection pump was controlled to be 1ml / h. The electrospinning solution of the core layer was loaded into another syringe, and the advancing speed of the micro-injection pump was controlled to be 0.2ml / h. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com