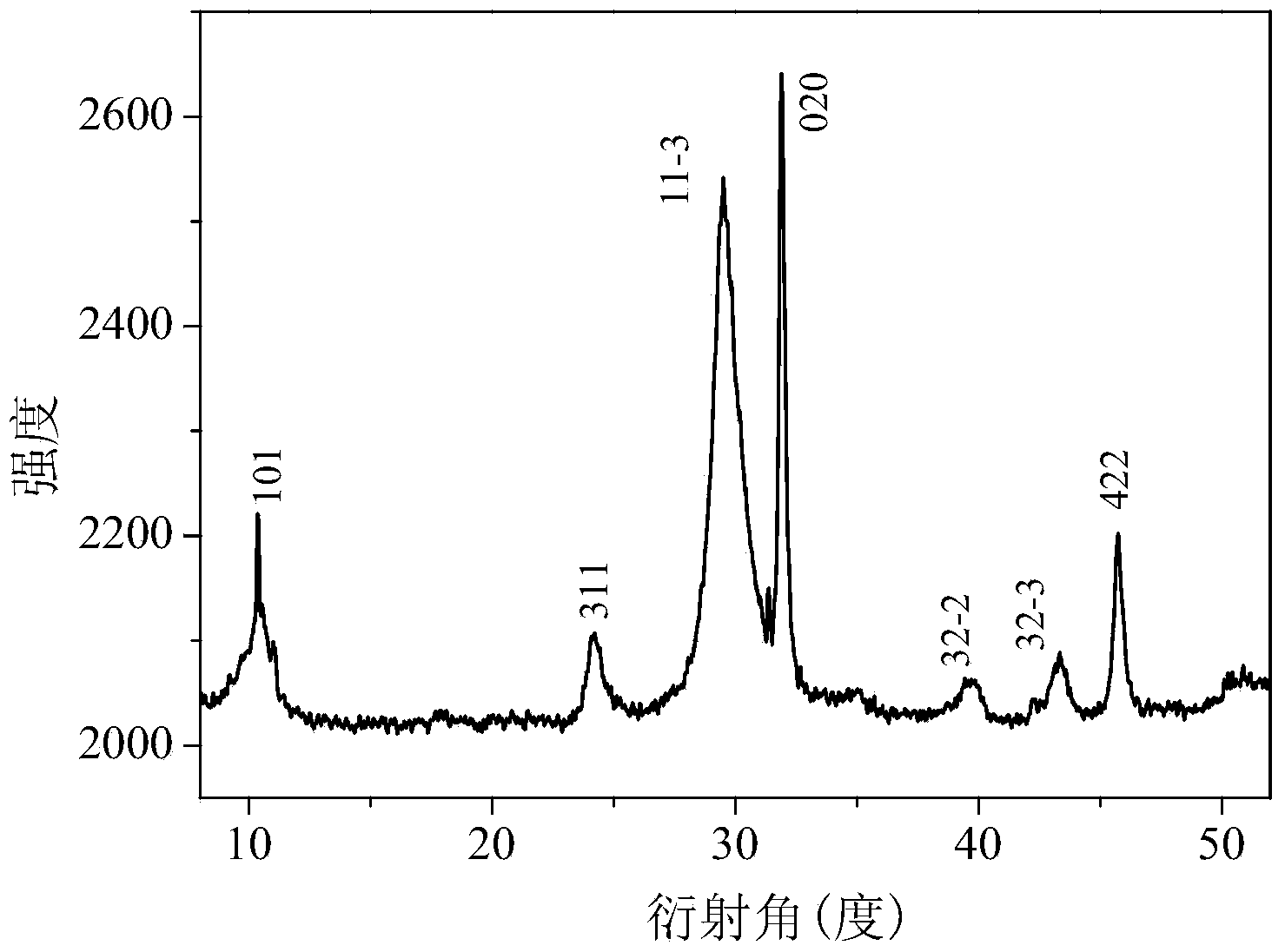

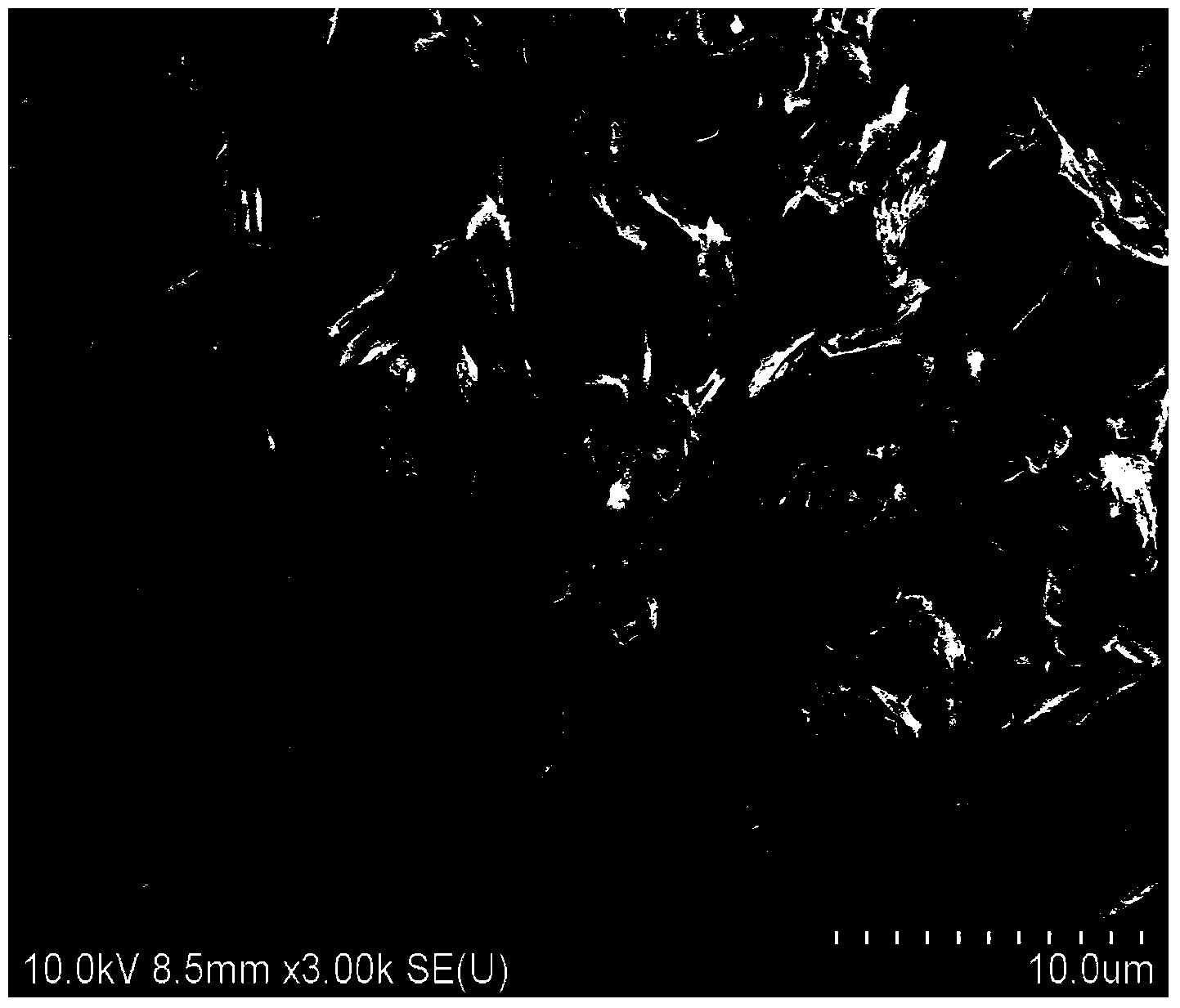

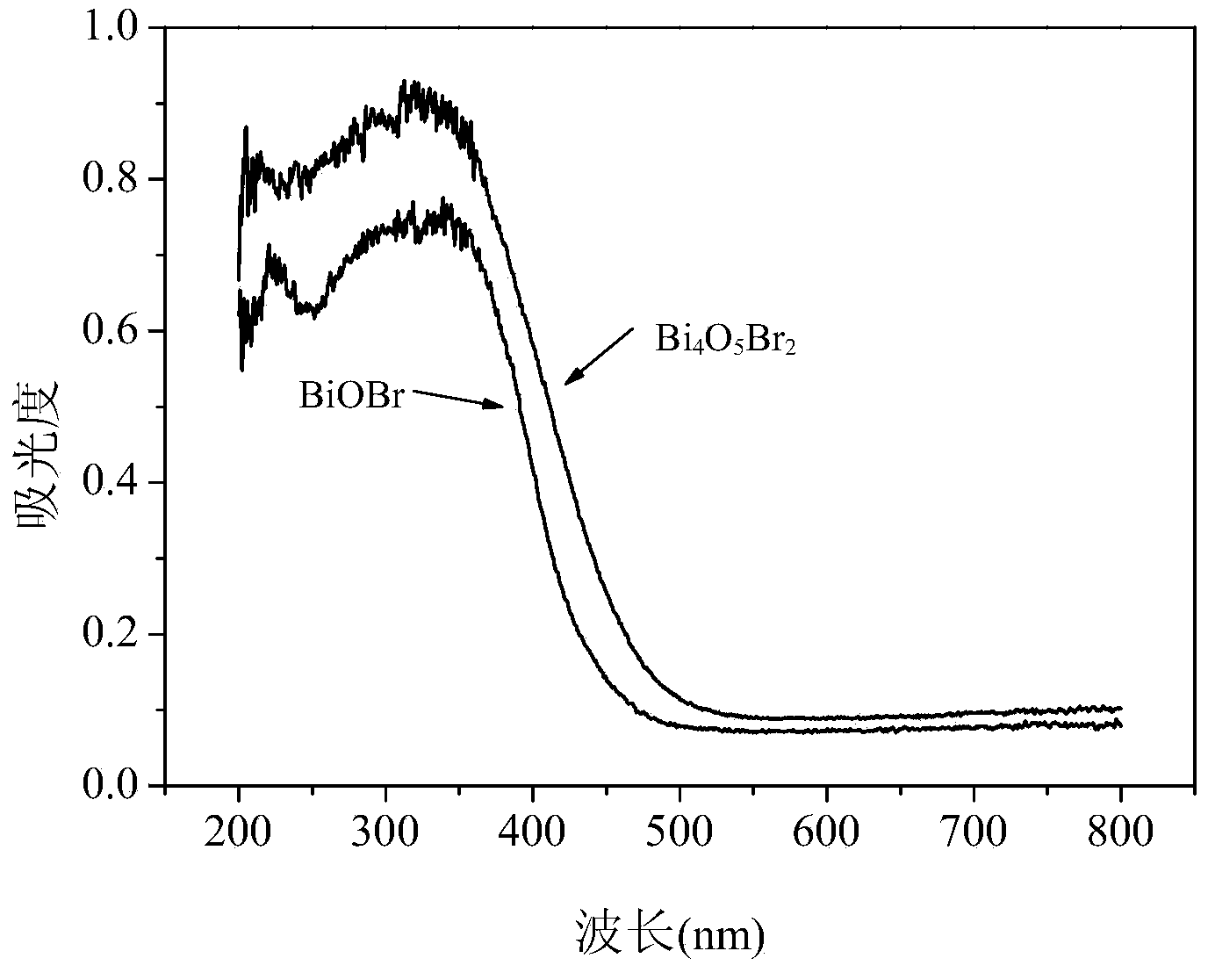

Visible-light-induced photocatalyst Bi4O5Br2 and preparation method thereof

A bi4o5br2, visible light technology, applied in the field of photocatalysis and material chemistry, can solve problems such as limiting practical application, and achieve the effects of improving photocatalytic performance, good visible light catalytic activity, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Weigh 2.0 grams of bismuth nitrate pentahydrate and dissolve it in 1.5 mL of concentrated nitric acid, add a small amount of water to dilute to 10 mL, and stir evenly;

[0026] Weigh 0.5 g of cetyltrimethylammonium bromide, dissolve it in 10 mL of deionized water, and stir evenly;

[0027] Slowly add the solution obtained in step to the solution obtained in step , adjust the pH value to 5.0 with 2mol / L sodium hydroxide solution, stir for 30min; transfer the mixture to 50mL polytetrafluoroethylene In a lined stainless steel hydrothermal kettle, control the volume of the solution to 40mL, and then perform hydrothermal treatment at a temperature of 160°C for 24 hours at a constant temperature;

[0028] After step , the solid product was separated by vacuum filtration, and the obtained solid product was washed with deionized water and absolute ethanol until neutral, and then dried at 80°C for 10 hours to obtain light yellow Bi 4 o 5 Br 2 solid powder.

Embodiment 2

[0030] Weigh 2.4 grams of bismuth nitrate pentahydrate and dissolve it in 1.5 mL of concentrated nitric acid, add a small amount of water to dilute to 10 mL, and stir evenly;

[0031] Weigh 0.75 g of cetyltrimethylammonium bromide and dissolve it in 10 mL of deionized water, and stir evenly;

[0032] Slowly add the solution obtained in step to the solution obtained in step , adjust the pH value to 5.0 with 2mol / L sodium hydroxide solution, stir for 30min; transfer the mixture to 50mL polytetrafluoroethylene In a lined stainless steel hydrothermal kettle, control the volume of the solution to 40mL, and then perform hydrothermal treatment at a temperature of 160°C for 24 hours at a constant temperature;

[0033] After step , the solid product was separated by vacuum filtration, and the obtained solid product was washed with deionized water and absolute ethanol until neutral, and then dried at 80°C for 24 hours to obtain light yellow Bi 4 o 5 Br 2 solid powder.

Embodiment 3

[0035] Weigh 1.5 grams of bismuth nitrate pentahydrate and dissolve it in 1.0 mL of concentrated nitric acid, add a small amount of water to dilute to 10 mL, and stir evenly;

[0036] Weigh 1.0 g of cetyltrimethylammonium bromide, dissolve it in 15 mL of deionized water, and stir evenly;

[0037] Slowly add the solution obtained in step to the solution obtained in step , adjust the pH value to 6.0 with 2mol / L sodium hydroxide solution, stir for 40min; transfer the mixture to 50mL polytetrafluoroethylene In a lined stainless steel hydrothermal kettle, control the volume of the solution to 40mL, and then perform hydrothermal treatment at a temperature of 160°C for 28 hours at a constant temperature;

[0038] After step , the solid product was separated by vacuum filtration, the obtained solid product was washed with deionized water and absolute ethanol to neutrality, and then dried at 60°C for 12 hours to obtain light yellow Bi 4 o 5 Br 2 solid powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com