Supported core-shell catalyst with oxide coated shell and metal nanoparticle core and preparation method thereof

An oxide and supported technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as complex preparation process, organic pollution, and difficult control , to achieve the effect of simple and easy-to-adjust operation method, uniform and controllable shell thickness, and easy-to-control reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

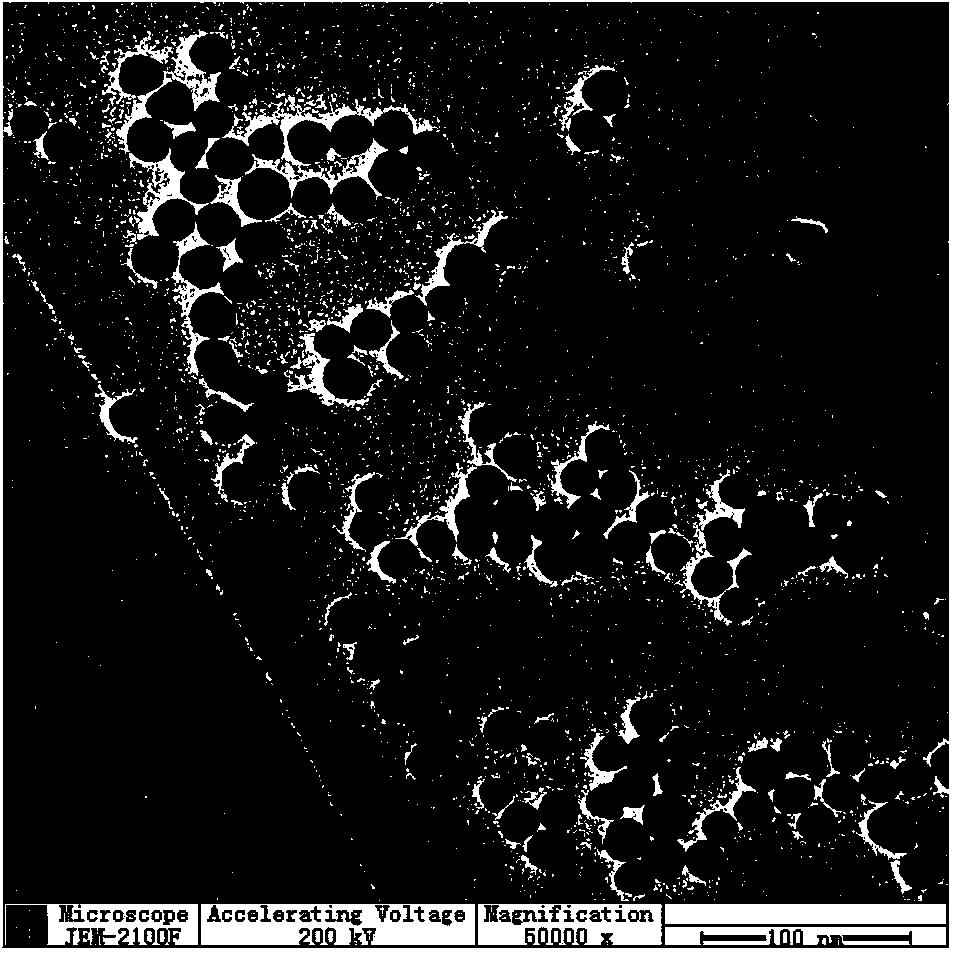

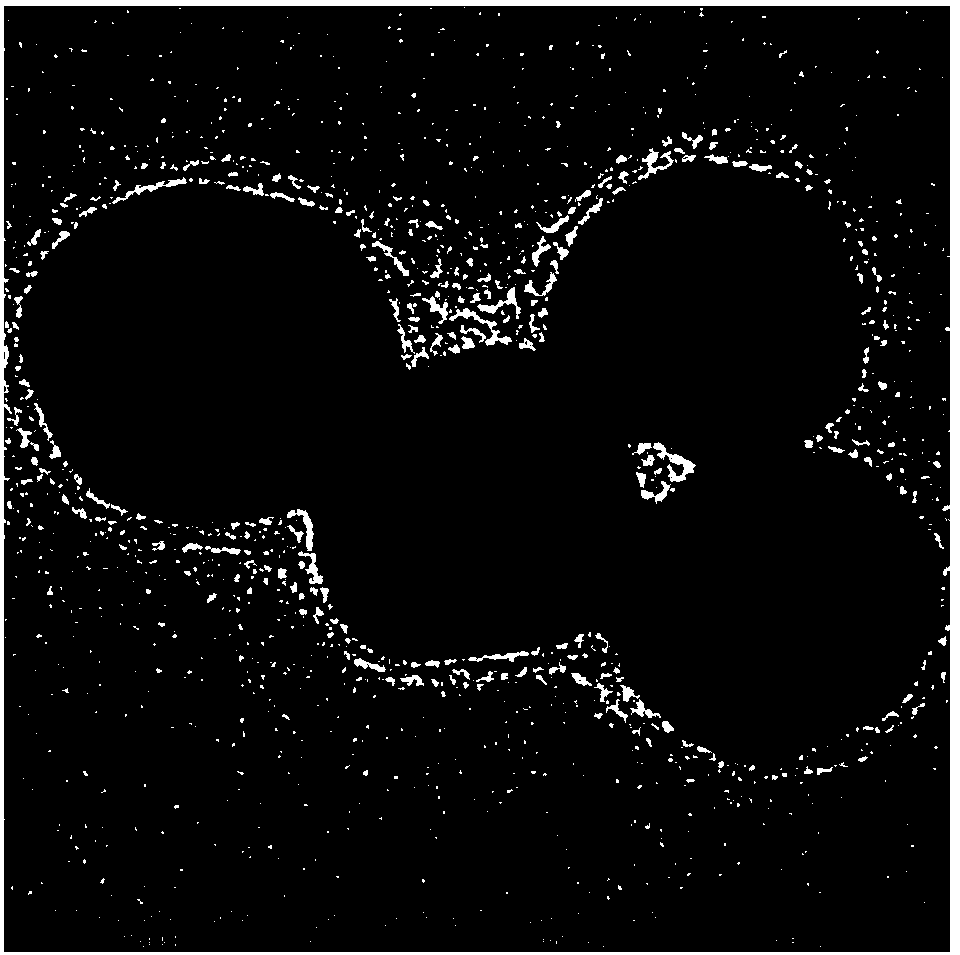

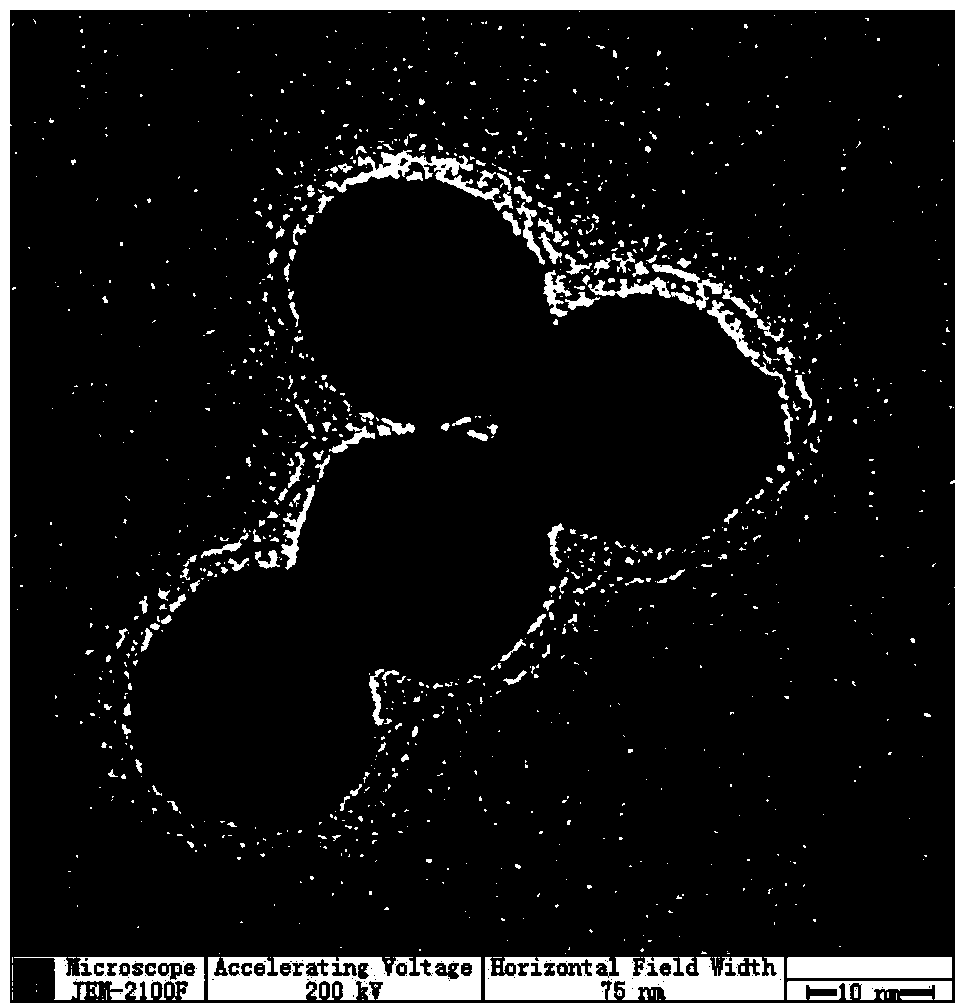

[0043] One: 1): Add 0.5ml24.28×10 to the round bottom flask equipped with reflux cold flow tube -3 mol / l of chloroauric acid. After vigorously stirring and heating to reflux, when the solution boils, quickly add 2.4ml sodium citrate (mass percentage 1%), stir for 30 min under boiling conditions, remove the heat source and cool to room temperature naturally to obtain 17nm Au nanoparticles for use. The TEM picture Such as figure 1 Shown. 2): Weigh 0.1736g of cerium nitrate and dissolve in 50ml of water, then add 0.126g of citric acid, 0.15g of ethylene glycol, and add 1.5% ammonia water dropwise to adjust the pH of the solution to 6.7.3): Take 50ml step 1) The resulting sol and 100ml. Step 2) The obtained solution is mixed and added to the lighting equipment, the wavelength of the light source is 200~800nm, and the intensity of the light source is 200mW / cm 2 , Control the reaction temperature to 25℃, illuminate for 15min, 45min, 2h to obtain AuCe 3+ Gel, its TEM picture such as ...

Embodiment 2

[0047] 1) Dissolve 4.7ml sodium citrate (mass fraction 1%) in 45ml water, stir vigorously for 15min, then pour it into a 100ml round bottom flask equipped with reflux cold flow tube, when it starts to boil, add 0.5ml Chloroauric acid (24.28×10 -3 mol / l), react for 30 minutes, and cool to room temperature to obtain 11nm Au nanoparticles for later use. 2): Weigh 0.1736g of cerium nitrate dissolved in 50ml of water, then add 0.126g of citric acid, 0.15g of ethylene glycol, and add 1.5% ammonia water to adjust the pH of the solution to 6.7.3): Take 50ml of the product obtained in step 1) Mix with 100ml of the product obtained in step 2) and add it to the lighting equipment. The wavelength of the light source is 200-800nm, and the light source intensity is 200mW / cm 2 , Control the temperature of the reaction solution to 25℃, and set the illumination time to 2h. 4): Centrifuge the final product at 10000r / min for 15min, take out the gel, dissolve it in 2ml of water, and immerse it in ...

Embodiment 3

[0049] First, add 0.5ml 24.28×10 to the round bottom flask equipped with reflux cold flow tube -3 mol / l of chloroauric acid. Then, after vigorous stirring and heating to reflux, when the solution boils, quickly add 1.4ml sodium citrate (mass fraction 2%), stir for 30 minutes under boiling conditions, remove the heat source and cool to room temperature naturally to obtain 22nm Au nanoparticles for later use.

[0050] The subsequent steps are exactly the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com