Preparation method of diffusion film coating composition, preparation method of diffusion film, and corresponding diffusion film

A diffusion film and composition technology, applied in the field of diffusion film, can solve the problems of reducing the haze of the diffusion film, uneven dispersion of particles, and affecting the uniformity and stability of optical properties, so as to improve the problem of agglomeration, reduce the process flow, The effect of excellent light transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

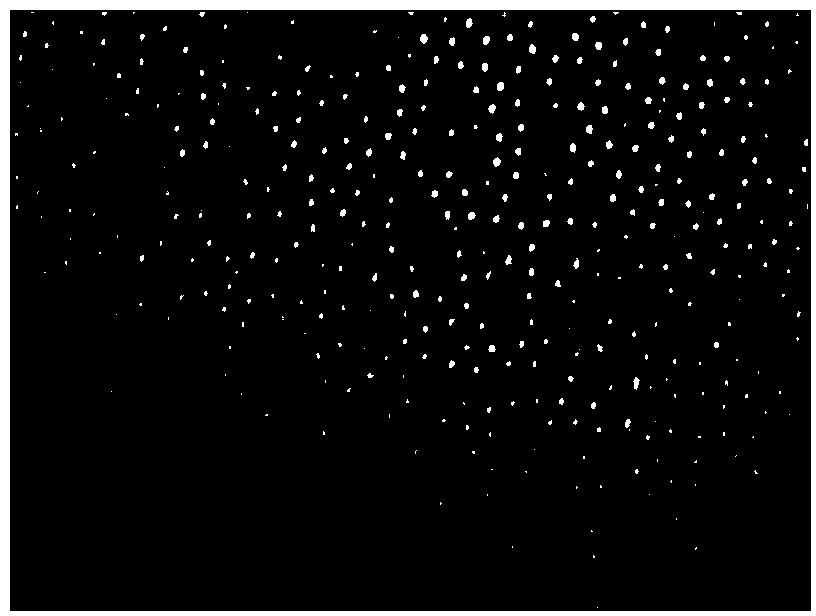

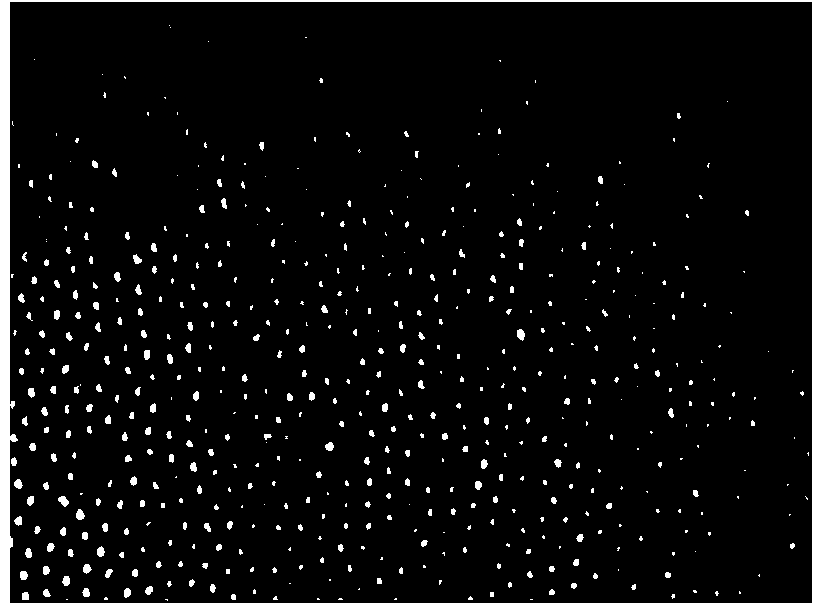

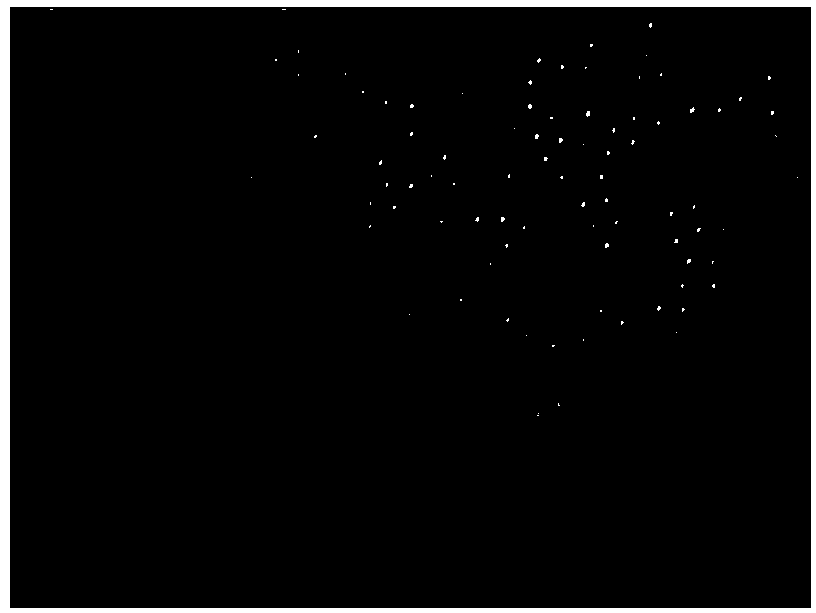

Image

Examples

Embodiment 1

[0047] Example 1: PS coated silica

[0048] Diffusion particle dispersion A:

[0049]Add 40.0 parts by weight of silicon dioxide microparticles (manufactured under the trade name, primary primary particle size is 5 μm) into the mixed solution of 100 parts by weight of absolute ethanol and 50 parts by weight of double distilled water, after mechanical stirring, fully Slowly add 3 parts by weight of stabilizer PVP [manufactured by BASF Co., Ltd., trade name: VA64], 15 parts by weight of vacuum distillation styrene dissolved with initiator AIBN under nitrogen conditions, and start heating to 70 ° C after stirring for 10 hours. 12h, this is the diffusion particle dispersion A.

[0050] Diffusion coating liquid composition:

[0051]

[0052] 37.6 parts by weight of water-based UV resin [manufactured by Bayer Material Science and Technology Corporation, trade name: UV2282], 36.4 parts by weight of trifunctional water-soluble aliphatic PUA [manufactured by Cytex Chemical Co., Lt...

Embodiment 2

[0054] Embodiment 2: PS wrapped calcium carbonate

[0055] Diffused Particle Dispersion B:

[0056] 34.0 parts by weight of calcium carbonate microparticles [manufactured by NEMOTO Co., Ltd., trade name: DSN-5, with an average particle diameter of 4.5 to 5.0 μm] were added to a mixed solution of 100 parts by weight of absolute ethanol and 50 parts by weight of propylene glycol, and mechanically After stirring, slowly add 3 parts by weight of stabilizer PVP [manufactured by BASF Co., Ltd., trade name: VA64], 15 parts by weight of vacuum distillation styrene dissolved with initiator AIBN under nitrogen-filled conditions, and start heating after stirring for 10 h To 70 ° C, react for 12 hours, this is the diffusion particle dispersion B.

[0057] Diffusion coating liquid composition:

[0058]

[0059] 37.6 parts by weight of oily UV resin [manufactured by Sartomer Chemical Co., Ltd., trade name: UV2282], 36.4 parts by weight of monofunctional reactive diluent [manufactured b...

Embodiment 3

[0061] Example 3: Polycarbonate Wrapped Silicone

[0062] Diffusion particle dispersion C:

[0063] Add 29.0 parts by weight of organosilicon microparticles [manufactured by Momentive High-tech Materials Group, trade name: Tospear145, with an average particle size of 6-7 μm] into a mixed solution of 100 parts by weight of absolute ethanol and 50 parts by weight of propylene glycol, and mechanically stir Finally, slowly add 3 parts by weight of stabilizer PVP [manufactured by BASF Co., Ltd., trade name: VA64], 11 parts by weight of the initiator AIBN that are dissolved in the underpressure distillation carbonate monomer [Zixin, Tai'an City] slowly and successively under nitrogen filling conditions. Manufactured by Chemical Co., Ltd., trade name: propylene carbonate], after stirring for 10 hours, start heating to 70°C, and react for 12 hours. This is the diffusion particle dispersion C.

[0064] Diffusion coating liquid composition:

[0065]

[0066] 78 parts by weight of o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com