A kind of transparent superhydrophobic nano-coating and its spraying preparation method

A nano-coating, super-hydrophobic technology, applied in the direction of coating, device for coating liquid on the surface, surface pretreatment, etc., to achieve the effect of high degree of transparency, reduced volatility and flammability, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] A preparation and spraying method of a transparent superhydrophobic nano-coating, the steps are:

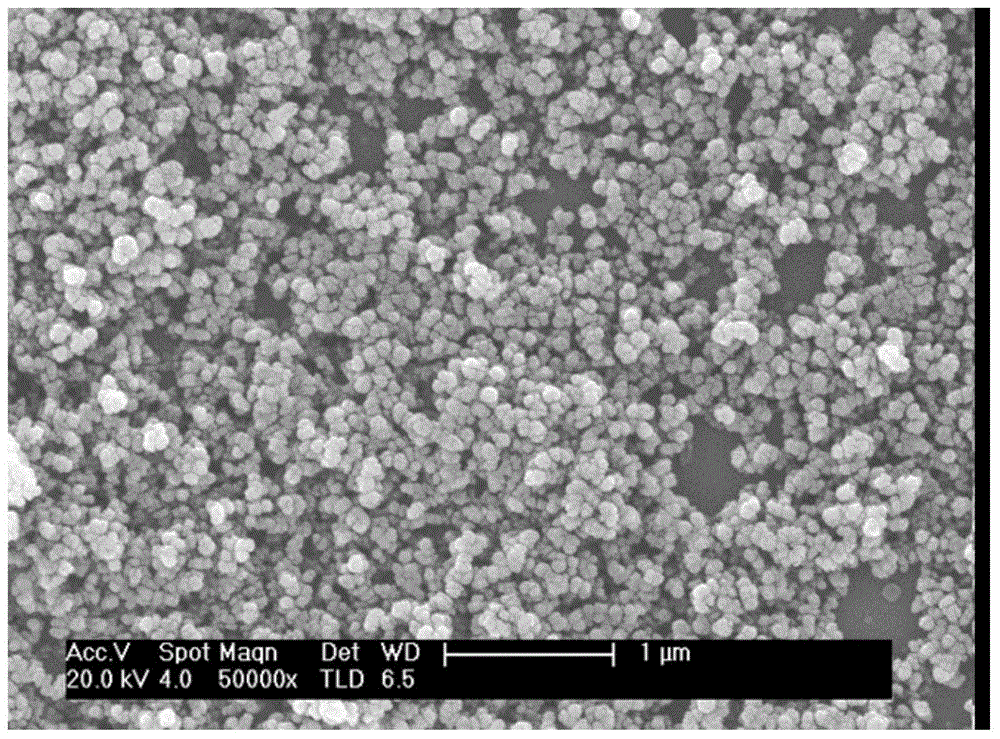

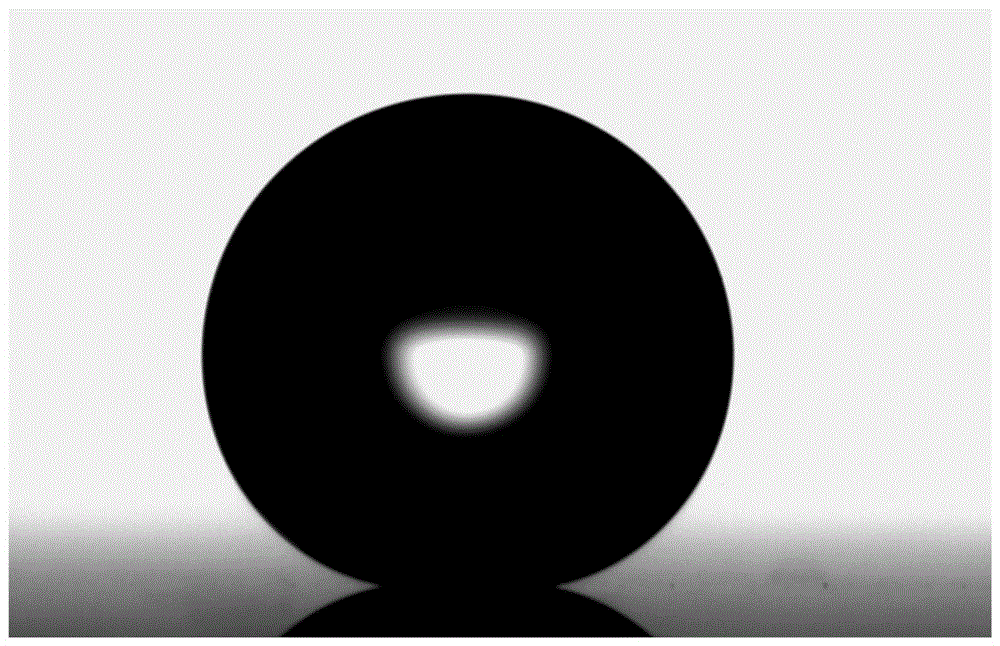

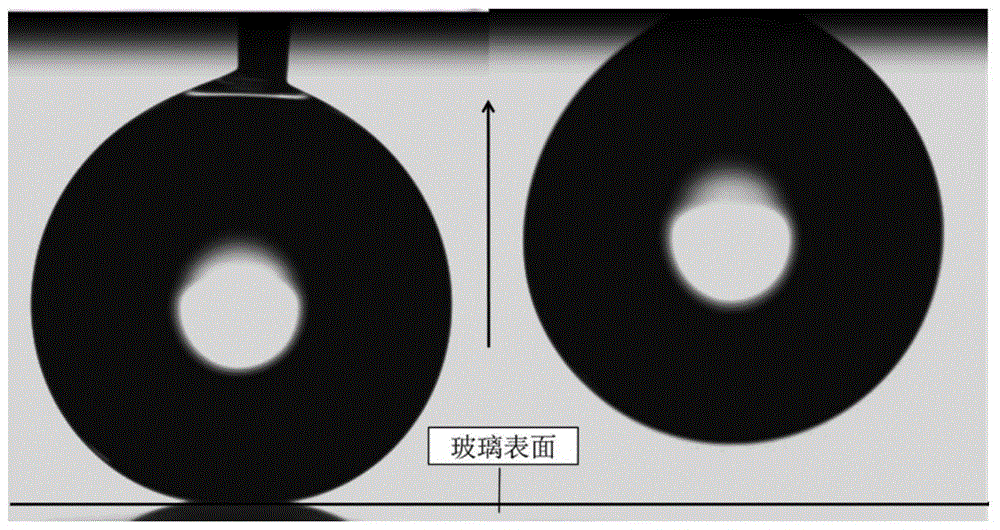

[0024] (1) Preparation of spray suspension: ultrasonically disperse hydrophobized fumed silica nanoparticles with a diameter of 15-40 nm in acetone solvent at a concentration of 5-20 mg / mL, and sonicate for 10-40 min. Subsequently, the silicone rubber prepolymer is also ultrasonically dissolved in acetone, the concentration is 2-10 mg / mL, and the ultrasonic time is 10-40 min. The equal volumes of the two solutions are fully mixed, and then ultrasonicated for 5-15 minutes to obtain an organic-inorganic hybrid emulsion. After that, add deionized water, the ratio of the added amount to the volume of the emulsion is 1:1-1:9, and then ultrasonically disperse for 10-30 minutes to obtain a spray suspension. The silicone rubber prepolymer is polydimethylsiloxane Alkanes and their derivatives, when preparing polydimethylsiloxane acetone solution, it is necessary to add a curing ag...

Embodiment 1

[0028] Hydrophobized fumed silica nanoparticles were ultrasonically dispersed in acetone solvent at a concentration of 5 mg / mL, and ultrasonicated for 10 min. Subsequently, polydimethylsiloxane (Sylgard184) was also dissolved in acetone at a concentration of 3 mg / mL, and a curing agent (Dow Corning, USA) was added at the same time in a weight ratio of 1 to polydimethylsiloxane :10, ultrasonic treatment for 10min on a power 150w ultrasonic dispersing device. The equal volumes of the two solutions were fully mixed, and then ultrasonicated for 5 minutes to obtain an organic-inorganic hybrid emulsion. After that, add deionized water, the ratio of the added amount to the volume of the emulsion is 1:9, and then ultrasonically disperse for 10 minutes to obtain a spray suspension.

[0029] Wipe the square glass with a side length of 50 cm with a cotton cloth. Ultrasonic the spray solution for 5 minutes before spraying, so that the silica nanoparticles and polydimethylsiloxane are unif...

Embodiment 2

[0032] Hydrophilic fumed silica nanoparticles were ultrasonically dispersed in acetone solvent at a concentration of 15 mg / mL, and ultrasonicated for 15 min. Subsequently, polydimethylsiloxane (Sylgard184) was ultrasonically dissolved in acetone at a concentration of 10 mg / mL, and a curing agent (Dow Corning, USA) was added at the same time, and the weight ratio of the added amount to polydimethylsiloxane was 1:10, ultrasonic time 20min. The equal volumes of the two solutions were fully mixed, and then ultrasonicated for 10 minutes to obtain an organic-inorganic hybrid emulsion. After that, add deionized water, the ratio of the added amount to the volume of the emulsion is 1:5, and then ultrasonically disperse for 15 minutes to obtain a spray suspension.

[0033] Clean the slide glass ultrasonically in ethanol for 5 minutes, take it out and dry it, blow it dry or dry it in the air for use. Ultrasonic the spray solution for 5 minutes before spraying, so that the silica nanopa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com