L-phenylalanine production process

A technology for phenylalanine and production process, which is applied in the field of separation technology, can solve the problems of high cost, low yield, serious environmental pollution and the like, and achieves the effects of reducing dosage, high elution rate and low consumption of ammonia water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

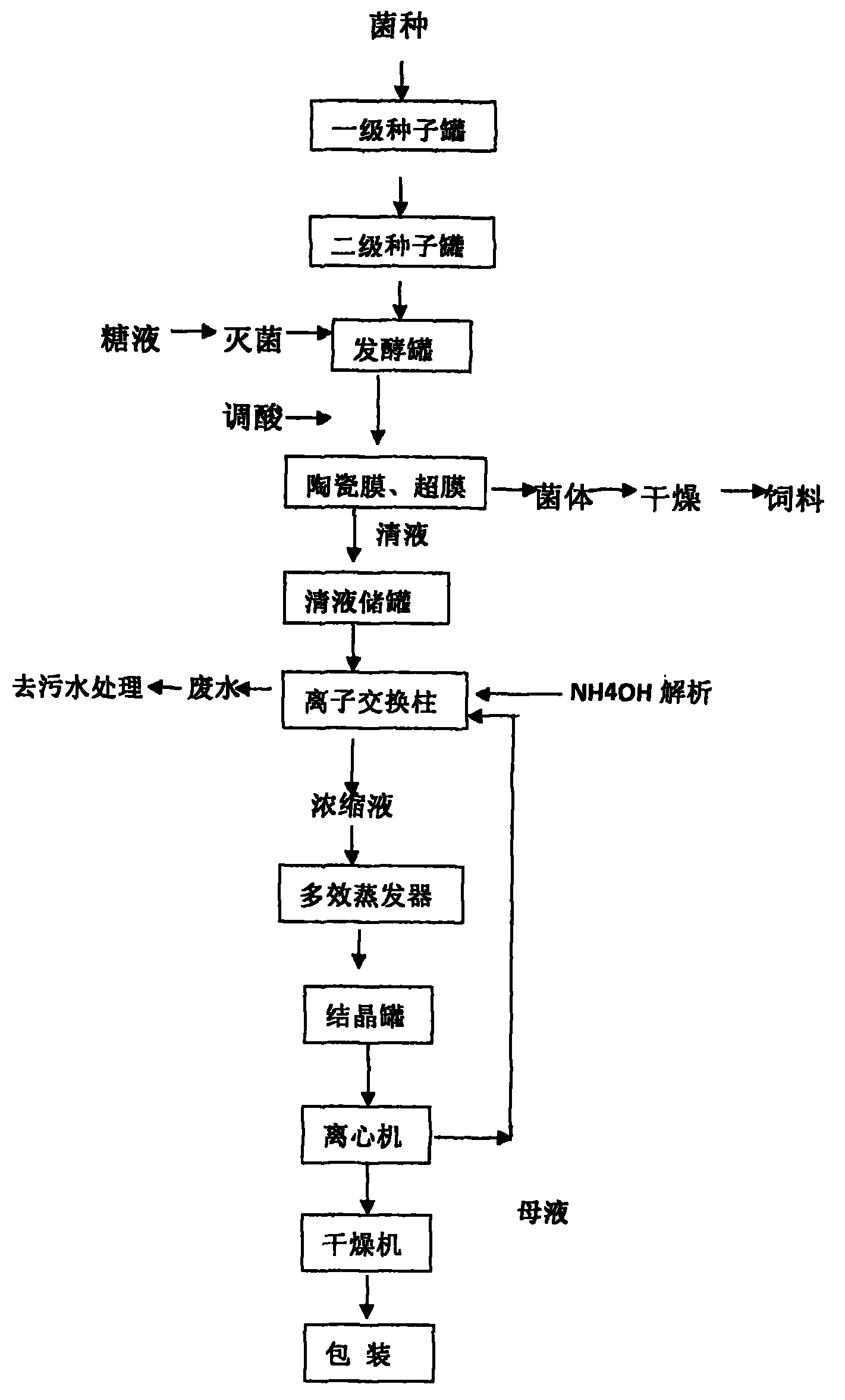

[0025] The present invention will be further described below in conjunction with accompanying drawing.

[0026] The production process of L-phenylalanine, as shown in the figure, comprises the following steps: 1. Kezi cultivation. Put 25mL of L-phenylalanine medium in a 250mL Erlenmeyer flask, inoculate the slant of the strain, and incubate at 37°C for 12h on a rotary shaker. After the seed tank has been boiled for 1 hour, then sterilized by air and sterilized, it is inserted into the medium for submerged cultivation of the seeds. 2. Fermentation. Using advanced concentrated sugar feeding process, the sterilized medium and strains are connected to a new type of aerobic automatic control fermenter, and the ingredients are fully automatically controlled. Under the condition of ventilation and stirring, the fermenter is continuously fed and sterilized The concentrated sugar solution of bacteria is used to ensure the smooth progress of fermentation and obtain a higher acid produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com