Method for preparing cuprous oxide thin film

A cuprous oxide and thin film technology is applied in the field of electrochemical material preparation, which can solve the problems of large particle size, unclear film phase composition and morphology, and electrolyte containing toxic components, so as to achieve simple operation and improve photoelectric conversion efficiency. , easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

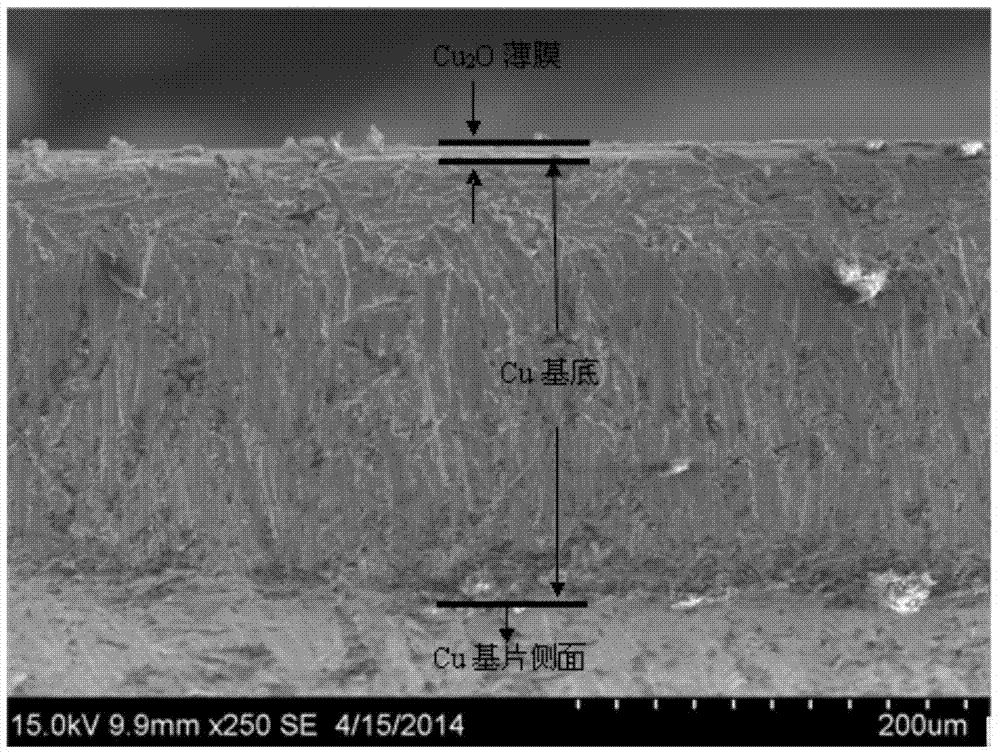

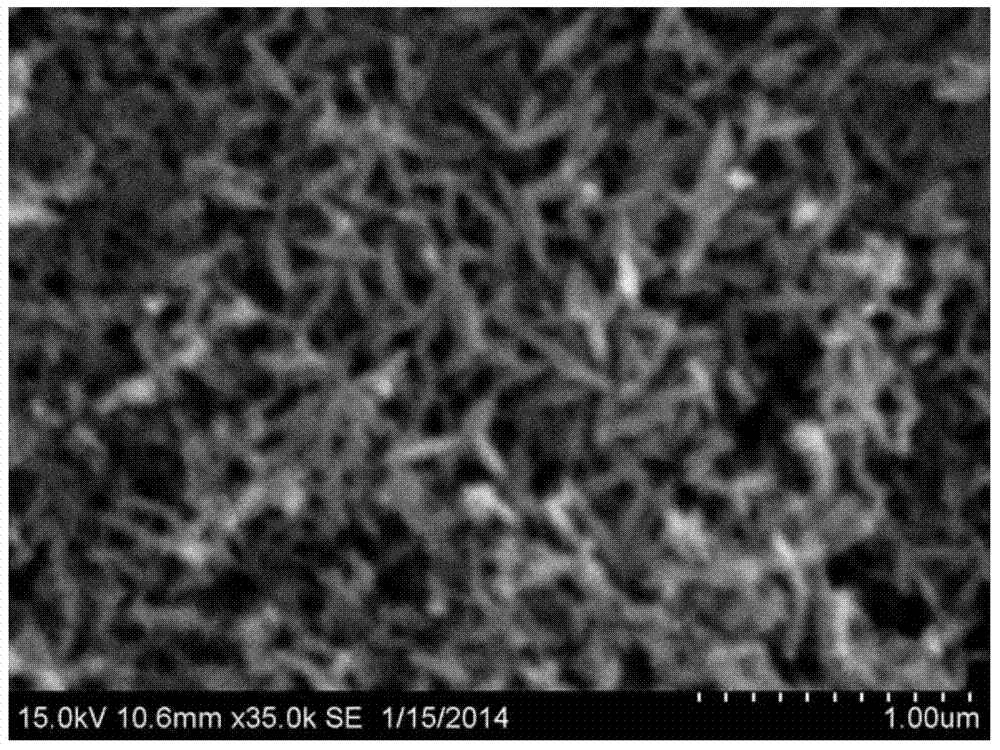

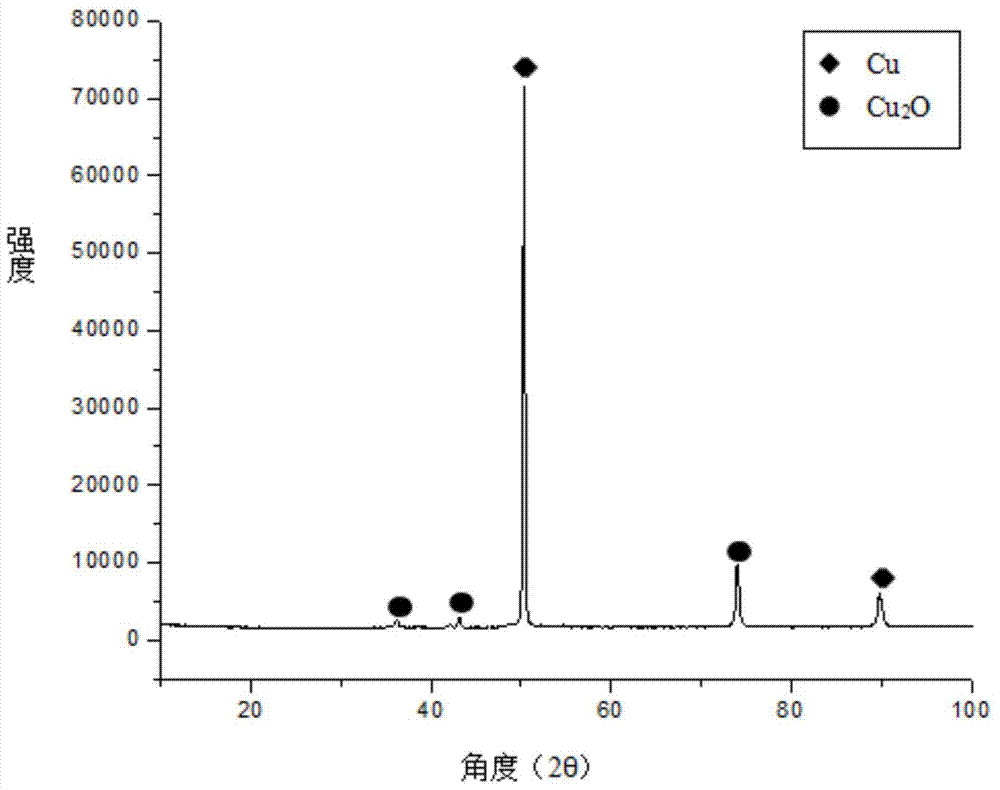

[0026] 1. Take a metal copper sheet with a size of 40mm×50mm×1mm, first use detergent to clean the oil stain on the surface, and then use 0.05mol / L sodium hydroxide aqueous solution and 0.05mol / L hydrochloric acid aqueous solution successively under ultrasonic conditions Ultrasonic immersion until the surface of the copper sheet is clean (about 5 to 10 minutes), then ultrasonic cleaning with absolute ethanol, and finally rinse with deionized water;

[0027] 2. At room temperature, use the copper sheet cleaned in step 1 as the anode, the platinum sheet as the cathode, and the 0.3mol / L sodium hydroxide aqueous solution as the electrolyte, under the electrolysis conditions of a DC voltage of 9V and a DC current of 0.7A Carry out the electrolysis reaction for 2 minutes, and stir the electrolytic solution at a rate of 300 rpm at the same time;

[0028] 3. At room temperature, use the copper sheet obtained in step 2 as the anode, the platinum sheet as the cathode, and the 0.03mol / L ...

Embodiment 2

[0034] 1. Take a metal copper sheet with a size of 40mm×50mm×1mm, first use detergent to clean the oil stain on the surface, and then use 0.05mol / L sodium hydroxide aqueous solution and 0.05mol / L hydrochloric acid aqueous solution successively under ultrasonic conditions Ultrasonic immersion until the surface of the copper sheet is clean (about 5 to 10 minutes), then ultrasonic cleaning with absolute ethanol, and finally rinse with deionized water;

[0035] 2. At room temperature, use the copper sheet cleaned in step 1 as the anode, the platinum sheet as the cathode, and the 0.1mol / L sodium hydroxide aqueous solution as the electrolyte, under the electrolysis conditions of a DC voltage of 8V and a DC current of 0.5A Carry out the electrolysis reaction for 3 minutes, and stir the electrolytic solution at a rate of 200 rpm at the same time;

[0036] 3. At room temperature, use the copper sheet obtained in step 2 as the anode, the platinum sheet as the cathode, and the 0.05mol / L ...

Embodiment 3

[0040]1. Take a metal copper sheet with a size of 40mm×50mm×1mm, first use detergent to clean the oil stain on the surface, and then use 0.05mol / L sodium hydroxide aqueous solution and 0.05mol / L hydrochloric acid aqueous solution successively under ultrasonic conditions Ultrasonic immersion until the surface of the copper sheet is clean (about 5 to 10 minutes), then ultrasonic cleaning with absolute ethanol, and finally rinse with deionized water;

[0041] 2. At room temperature, use the copper sheet cleaned in step 1 as the anode, the platinum sheet as the cathode, and the 0.5mol / L sodium hydroxide aqueous solution as the electrolyte, under the electrolysis conditions of a DC voltage of 10V and a DC current of 1.0A Carry out the electrolysis reaction for 1min, and stir the electrolytic solution at a rate of 400rpm at the same time;

[0042] 3. At room temperature, use the copper sheet obtained in step 2 as the anode, the platinum sheet as the cathode, and the 0.01mol / L sodium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com