A kind of preparation method of lithium-ion battery spherical cathode material

A technology for lithium-ion batteries and positive electrode materials, which is applied in the field of preparation of lithium-ion battery positive electrode materials, can solve the problems of low efficiency of lithium-ion battery materials for the first time, and achieve the effects of large-scale production, low energy consumption, and short reaction cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

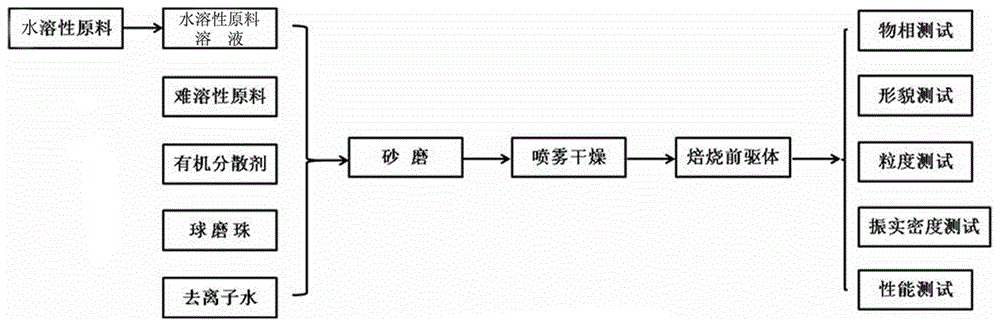

Method used

Image

Examples

Embodiment 1

[0052] Example 1 Lithium-ion battery cathode material [Nitric acid] copper doped LiFePO 4 Preparation

[0053] 1. Screening of raw materials and calculation of theoretical addition

[0054] Raw materials: lithium carbonate (purity of 99.9%), copper nitrate (purity of 99%), phosphoric acid (purity of 85%), ferrous oxalate (purity of 99.5%).

[0055] Dispersant: polyethylene glycol PEG10000.

[0056] Carbon source: sucrose.

[0057] Synthesis of 2Kg copper doped LiFePO 4 The amount of raw materials to be added is as follows:

[0058] m(lithium carbonate Li 2 CO 3 )=0.489Kg

[0059] m(copper nitrate Cu(NO 3 ) 2 ·3H 2 O)=61.815g

[0060] m(phosphoric acid H 3 PO 4 )=1.462Kg

[0061] m (ferrous oxalate FeC 2 O 4 ·2H 2 O)=2.25Kg

[0062] m(PEG10000)=100g

[0063] m(sucrose)=200g

[0064] Zirconia ball: diameter Φ2mm, weight 5Kg

[0065] Deionized water: 4Kg.

[0066] 2. Preparation method

[0067] 1. Horizontal sand mill mixed processing raw materials:

[0068] Mix 61.815g of copper nitrate, 1.462Kg of ...

Embodiment 2

[0077] Example 2 LiCo Ternary Cathode Material LiCo 1 / 3 Mn 1 / 3 Ni 1 / 3 O 2 Preparation

[0078] 1. Screening of raw materials and calculation of theoretical addition

[0079] Raw materials: lithium carbonate (purity of 99.9%), nickel acetate (purity of 99.9%), manganese acetate (purity of 99.9%), cobalt acetate (purity of 99.9%);

[0080] Dispersant: polyethylene glycol PEG10000;

[0081] Synthesize 2kg ternary cathode material LiCo 1 / 3 Mn 1 / 3 Ni 1 / 3 O 2 The amount of raw materials to be added is as follows:

[0082] m(lithium carbonate Li 2 CO 3 )=1.53Kg

[0083] m(Cobalt acetate C 4 H 6 O 4 Co·4H 2 O)=1.72Kg

[0084] m(Manganese acetate C 4 H 6 O 4 Mn·4H 2 O)=1.69Kg

[0085] m(nickel acetate C 4 H 6 O 4 Ni·4H 2 O)=1.72Kg

[0086] m(PEG10000)=200g

[0087] Zirconia ball: diameter Φ2mm, weight 5Kg

[0088] Deionized water: 4Kg.

[0089] 2. Preparation method

[0090] 1. Horizontal sand mill mixed processing raw materials:

[0091] Add 1.72Kg of cobalt acetate, 1.72Kg of nickel acetate and 1.69Kg ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com