A kind of hollow structure spinel type mesoporous high entropy oxide nanosphere and its preparation method and application

A spinel type, hollow structure technology, applied in the field of nanomaterials, to achieve the effect of controlling cost input and wide application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

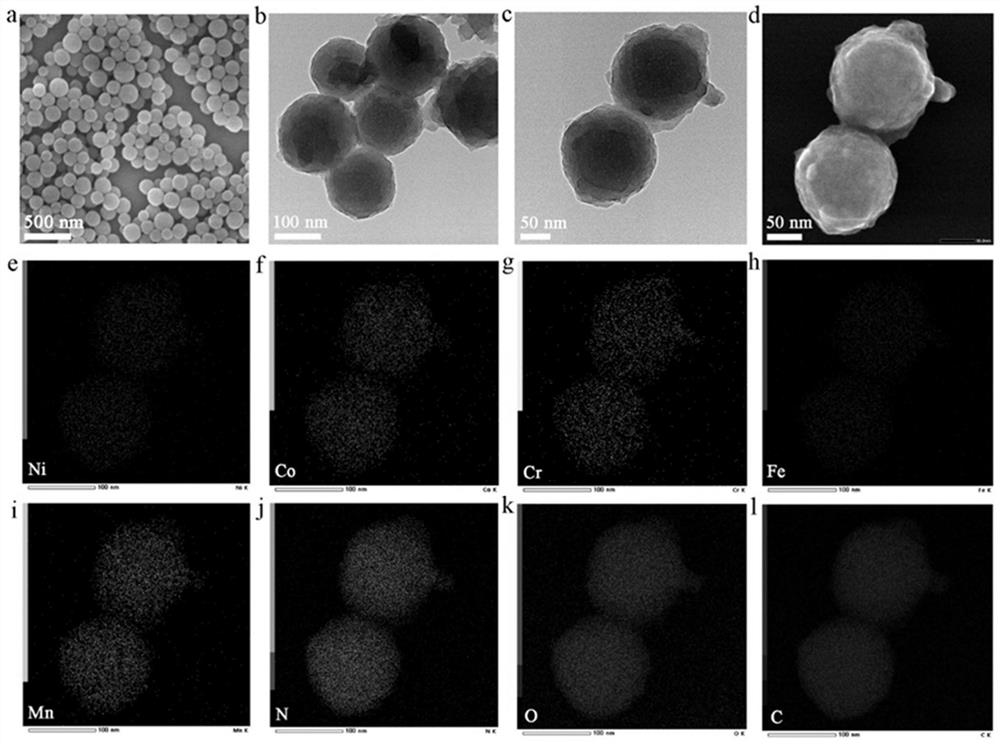

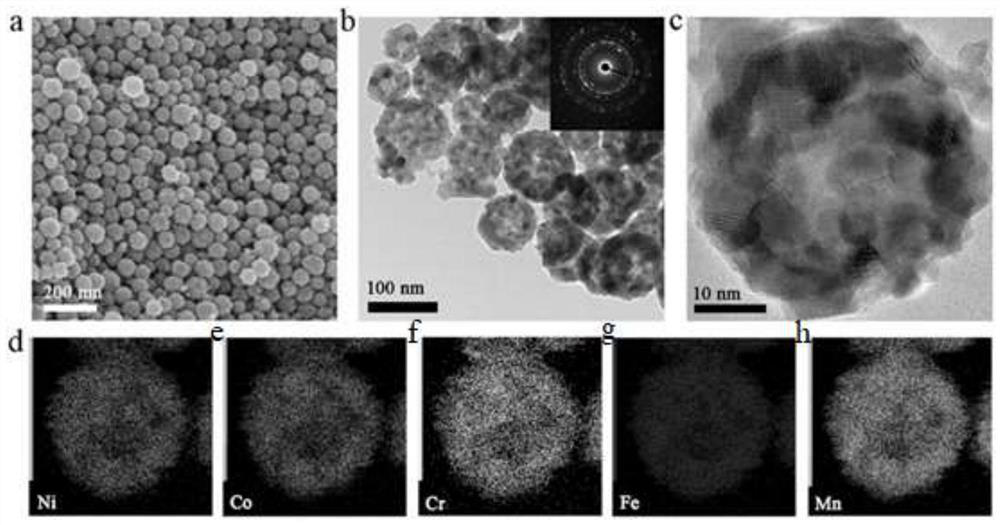

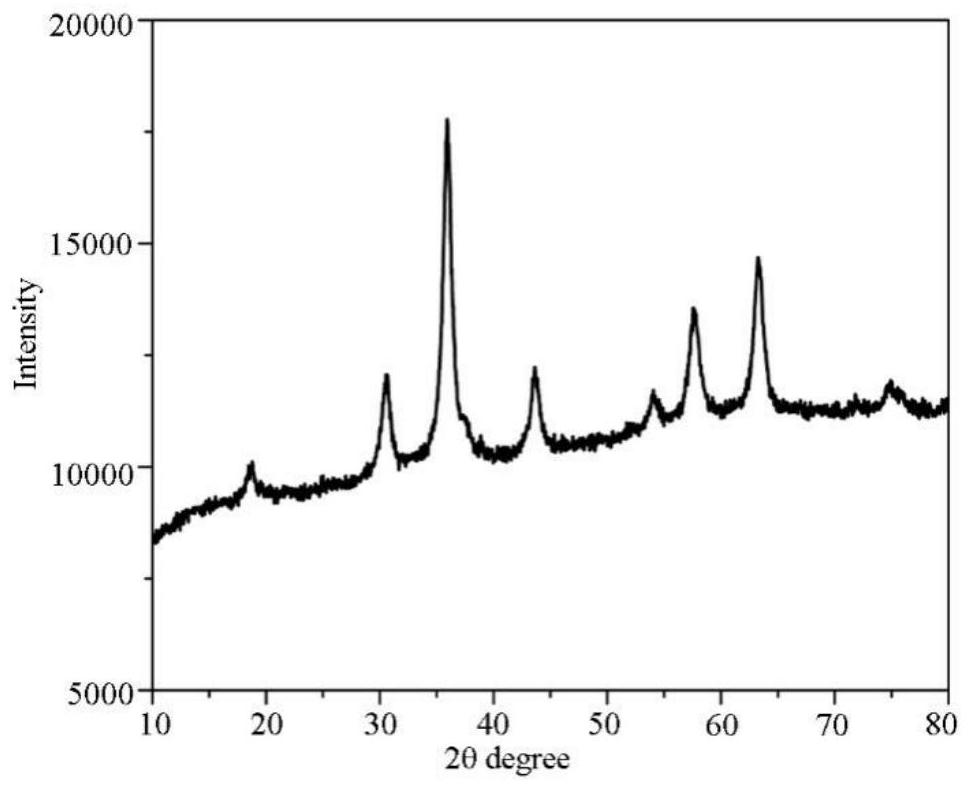

[0039] The spinel-type mesoporous high-entropy oxide (NiCoCrFeMn) with a hollow structure provided by the present invention 3 o 4 Nanosphere and preparation method, concrete steps are as follows:

[0040] (1) In a weakly alkaline water / alcohol mixed solvent, plant polyphenol tannic acid is used as an organic ligand, and Pluronic F127 is used to control the morphology. First, formaldehyde covalently cross-links tannic acid to form tannin acid-formaldehyde oligomer, then Ni 2+ 、Co 2+ 、Cr 3+ , Fe 2+ , Mn 2+ Aqueous solution of nickel(II)-cobalt(II)-chromium(III)-iron(II)-manganese(II)-tannic acid-formaldehyde polymer nanospheres.

[0041] (2) With the prepared nickel (II)-cobalt (II)-chromium (III)-iron (II)-manganese (II)-tannic acid-formaldehyde polymer nanospheres as a precursor, in an air atmosphere for 600 ℃ roasting 1-3h in the system.

Embodiment 1

[0043] Mesoporous High Entropy Oxides (NiCoCrFeMn) 3 o 4 Synthesis of hollow nanospheres:

[0044] (1) Dissolve 0.20g Pluronic F127 in 38mL H 2 0 and 8 mL of absolute ethanol, after completely dissolving, add 0.35 mL of ammonia water (25 wt %), stir for about 1 h, then add 8 mL of tannic acid aqueous solution (containing 0.20 g of tannic acid) and 0.38 mL of formaldehyde solution (37 to 40 wt %) , Continue stirring for 12h, covalent cross-linking reaction occurs, and tannic acid-formaldehyde oligomer is obtained.

[0045] (2) Add 2 mL of freshly prepared Ni(NO 3 ) 2 , Co(NO 3 ) 2 , CrCl 3 , FeSO 4 , MnSO 4 For the mixed solution, the molar concentration of the metal salt is 0.069mM, and the corresponding masses are 0.02g, 0.02g, 0.018g, 0.02g, and 0.012g, respectively. After stirring for 12h, the resulting mixture was transferred to a 100mL reaction kettle, heated in an oven at 100°C for 12h, and then the hydrothermal product was collected by centrifugation, and furt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com