Photosensitive resin composition for CTP flexographic printing original plates and printing original plate obtained from same

A technology of photosensitive resin and flexographic printing, which is applied in the field of photosensitive resin composition, and can solve problems such as uneven transfer of ink, easy deformation of the shape of the top area of the relief, and blurred printing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1A

[0063] Butadiene latex (Nippol LX 111NF, manufactured by Nippon Zeon Co., Ltd.) (45 parts by mass (solid system)) and 10 parts by mass (solid system) of acrylonitrile-butadiene latex (Nippol SX 1503, manufactured by Nippon Zeon Co., Ltd.) As component (A); 12 parts by mass (solid system) of a hydrophilic polymer (PFT-3 manufactured by Kyoeisha Chemical Co., Ltd.) as component (B); 12 parts by mass of oligobutadiene acrylate ( ABU-4 manufactured by Kyoeisha Co., Ltd.) as component (C-1), 7.5 parts by mass of glycol monomethacrylate (G101P manufactured by Kyoei Chemical Co., Ltd.) as component (C-2), and 7.5 Parts by mass of lauryl methacrylate as component (C-3) (ie they are component (C)); 0.7 parts by mass of photopolymerizable initiator as component (D); 0.03 parts by mass of terephthalic Phenol monoethyl ether as a polymerization inhibitor; and 0.04 parts by mass of a carboxylate-type copolymer as other additives were mixed in a container together with 15 parts by mass of t...

Embodiment 2A-6A and comparative example 1A-6A

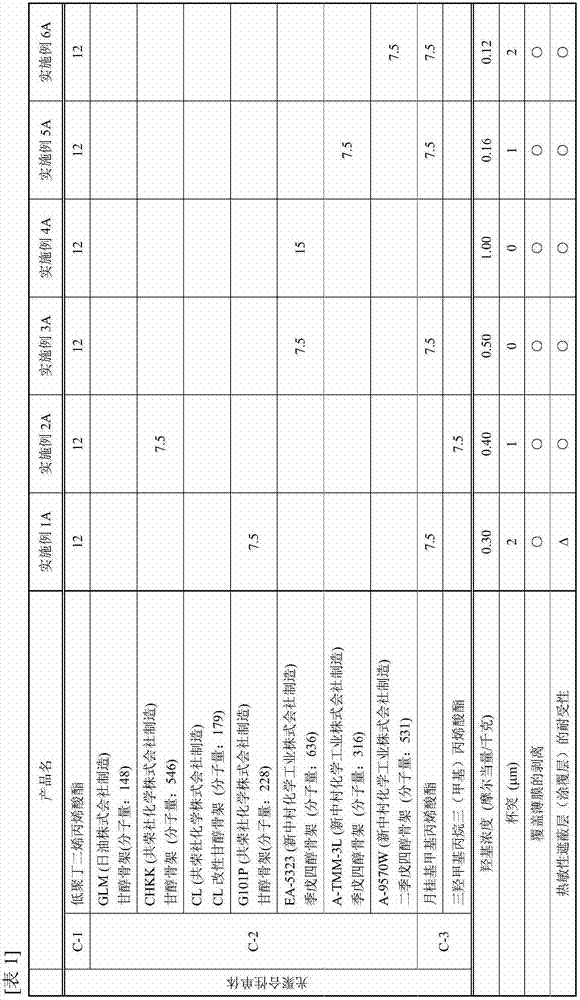

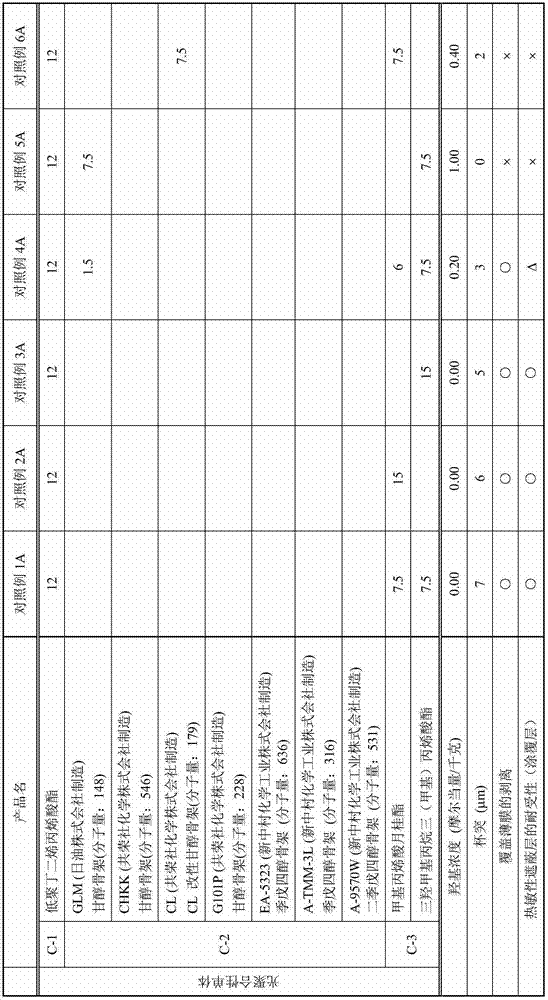

[0065] As for Examples 2A-6A and Comparative Examples 1A-6A, the photosensitive resin composition and resin master plate were prepared and evaluated in the same manner as in Example 1A, except that components (C-2) and (C-3) were as shown in the table 1 make changes other than indicated. Details of the photosensitive resin composition (only for component (C)) and evaluation results are shown in Table 1.

[0066]

[0067]

[0068] As apparent from the results in Table 1, the products using the photosensitive resin compositions of Examples 1A-6A exhibited excellent and well-balanced cupping properties, peelability of cover films, and resistance to heat-sensitive masking layers (coating layers). sex.

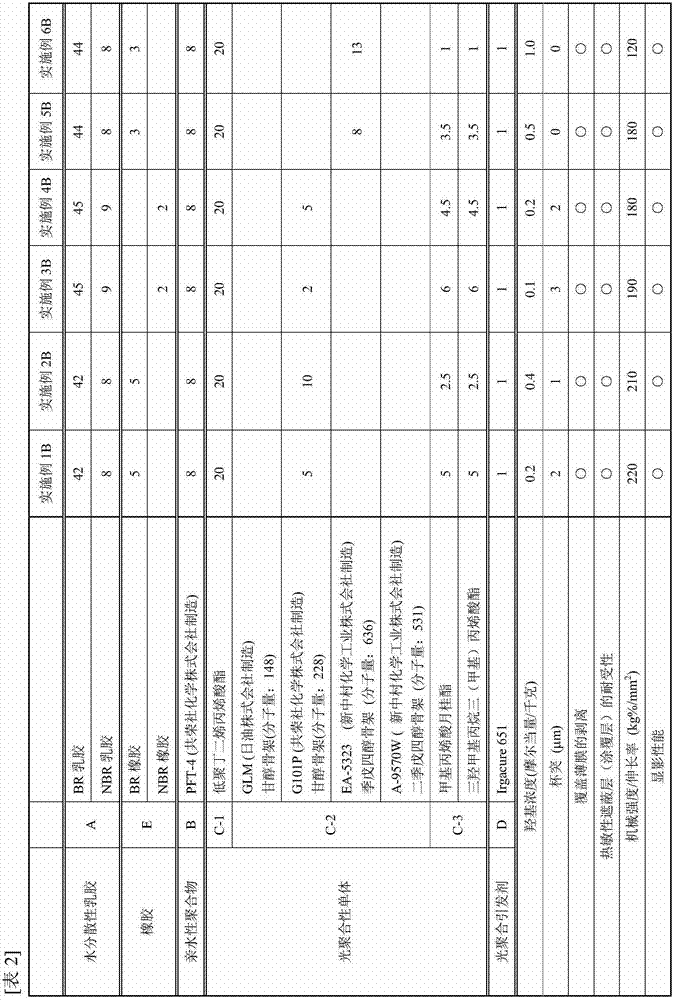

Embodiment 1B

[0070] Polybutadiene latex (Nippol LX 111 NF, manufactured by Nippon Zeon Co., Ltd.) (42 parts by mass (solid system)) and 8 parts by mass (solid system) of acrylonitrile-butadiene copolymer latex (Nippol SX 1503, Nippon Zeon Co., Ltd.) as component (A), 5 parts by mass (solid system) of BR rubber (Nippol BR 1220, manufactured by Nippon Zeon Co., Ltd.) as component (E) and 80 parts by mass of toluene were heated at 60° C. to prepare A liquid in which rubber is dissolved. Let it cool down to room temperature. 8 parts by mass (solid system) of a hydrophilic polymer (PFT-4 manufactured by Kyoeisha Chemical Co., Ltd.) as component (B), 20 parts by mass of oligobutadiene acrylate (Kyoeisha Chemical Co., Ltd.) were added thereto. Co., Ltd. manufactured ABU-4) as component (C-1), 5 parts by mass of glycol dimethacrylate (G 101P manufactured by Kyoeisha Chemical Co., Ltd.) as component (C-2), 5 parts by mass Parts by mass of lauryl methacrylate and 5 parts by mass of trimethylolprop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight-average molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com