A kind of preparation method of sustained-release vitamin E derivative preparation

A vitamin and derivative technology, applied in the field of medicine and chemical industry, can solve problems such as no resistant starch, no slow-release vitamin E preparation, etc., and achieve the effects of being beneficial to absorption, reducing production costs and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

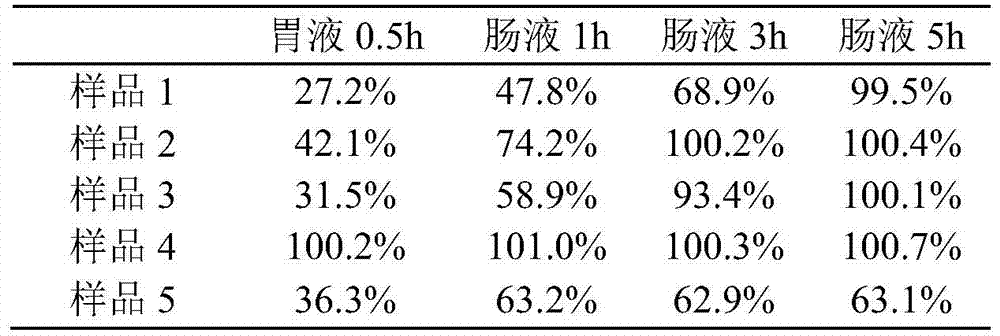

Examples

Embodiment 1

[0039] 1) Add 100kg of dry corn starch and 150kg of water into the reactor, control the jacket temperature to 70°C, and the stirring speed to 200 rpm, add 10kg of 37% concentrated hydrochloric acid under the control of a metering valve, and hydrolyze for 15 minutes to obtain a part Hydrolyzed starch milk.

[0040] 2) Neutralize the partially hydrolyzed starch milk obtained in step 1) with 1% aqueous sodium hydroxide solution to a pH value of 7.5, then adjust the jacket temperature to 30°C, and the stirring speed to 100 rpm. Add 3 kg of octenyl succinic anhydride under control, and automatically add 1% aqueous sodium hydroxide solution to control the pH value of the reaction solution in the kettle at 7.5, and react for 120 minutes to obtain starch milk after esterification.

[0041] 3) Filtration, the filter cake was mixed with 100 kg vitamin E acetate, then ground for 2 hours, then transferred to a drying device.

[0042] 4) Steam is passed into the drying device to dry the g...

Embodiment 2

[0045] 1) Add 100kg of dry-based potato starch and 200kg of water into the reactor, control the jacket temperature to 40°C, and the stirring speed to 100 rpm, add 1kg of 37% concentrated hydrochloric acid under the control of a metering valve, and hydrolyze for 60 minutes to obtain partial hydrolysis After the starch milk.

[0046] 2) Neutralize the partially hydrolyzed starch milk obtained in step 1) with sodium hydroxide to a pH value of 9.0, then adjust the jacket temperature to 50°C, and the stirring speed to 200 rpm, and add 0.5 kg of Octenyl succinic anhydride, and automatically control the addition of sodium hydroxide to control the pH value of the reaction solution in the kettle at 9.0, and react for 60 minutes to obtain starch milk after esterification.

[0047] 3) Filtration, the filter cake was mixed with 100kg vitamin E acetate, then ground for 0.5 hours, then transferred to a drying device.

[0048] 4) Steam is fed into the drying device to dry the ground product...

Embodiment 3

[0051] 1) Add 100kg of dry waxy cornstarch and 160kg of water into the reaction kettle, control the jacket temperature to 50°C, and the stirring speed to 150 rpm, add 2kg of 37% concentrated hydrochloric acid under the control of a metering valve, and hydrolyze for 30 minutes to obtain part Hydrolyzed starch milk.

[0052] 2) Neutralize the partially hydrolyzed starch milk obtained in step 1) with sodium hydroxide to a pH value of 8.0, then adjust the jacket temperature to 40°C, and the stirring speed to 150 rpm, and add 2.5 kg of Octenyl succinic anhydride, and automatically control the addition of sodium hydroxide to control the pH value of the reaction solution in the series tank at 8.0, and react for 90 minutes to obtain starch milk after esterification.

[0053] 3) Filtration, the filter cake was mixed with 100 kg vitamin E acetate, then ground for 1.5 hours, then transferred to a drying device.

[0054] 4) Steam is passed into the drying device to dry the ground product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com