Fe3O4-poly-dopamine-Au nano-composite material as well as preparation method and application thereof

A nanocomposite material, polydopamine nanotechnology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalyst, color/spectral characteristic measurement, etc., can solve the problem of low catalyst utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

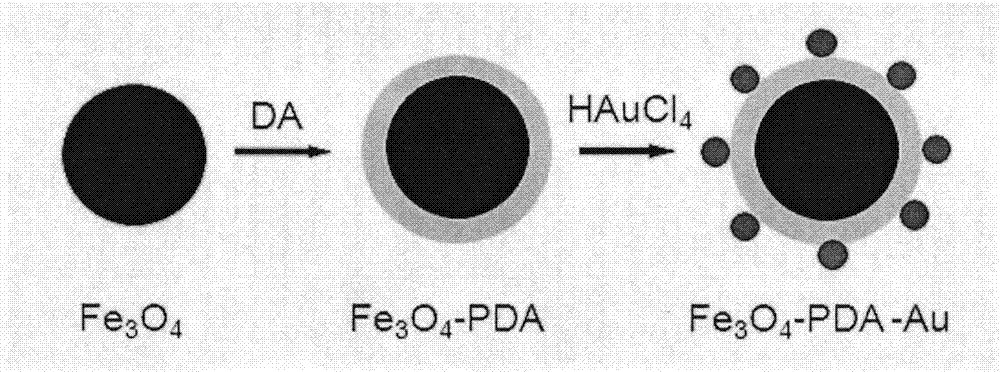

[0023] The present invention also provides a kind of Fe 3 o 4 - Preparation of polydopamine-Au nanocomposites, see figure 1 , which includes the following steps:

[0024] Step 1: Fe with a diameter of 200-250 nm 3 o 4 Nano-magnetic beads are dispersed into a buffer solution with a pH of 8.5, and stirred, wherein the concentration of the buffer solution is maintained at 8-12 mmol / L;

[0025] Step 2: adding dopamine hydrochloride to the reaction system, and reacting for 3 to 24 hours to obtain the initial Fe 3 o 4 - polydopamine nanoparticles, wherein the Fe 3 o 4 The mass ratio of the nano magnetic beads to the dopamine hydrochloride is 1:0.8~1:1.2;

[0026] Step 3: the initial Fe 3 o 4 - the polydopamine nanoparticles are dispersed into the buffer solution with a pH of 8.5 again, and step 2 is repeated 1 to 2 times to obtain Fe 3 o 4 - polydopamine particles;

[0027] Step 4: the Fe 3 o 4 - Polydopamine particles are prepared into a dispersion with a mass concen...

Embodiment 1

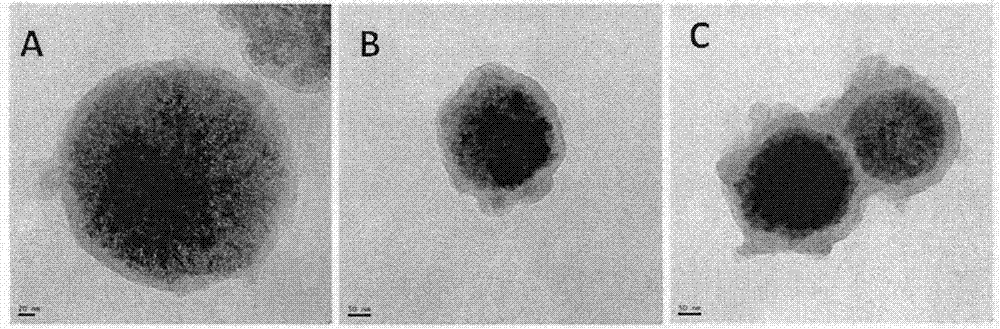

[0035] 0.325g anhydrous FeCl 3 Disperse with 0.2g sodium citrate in 20mL ethylene glycol, stir for 1 hour to completely dissolve the solid; then add 1.2g sodium acetate and stir for 30 minutes. The mixture was added to a hydrothermal reaction kettle with a volume of 50 mL, put into an oven, and kept at 200° C. for 12 hours, and was taken out when the reaction kettle was cooled to room temperature. The black precipitate at the bottom of the reaction kettle is Fe 3 o 4 Nano-magnetic beads, using a magnet for magnetic separation, the obtained Fe 3 o 4 Wash with water and ethanol three times respectively, and dry under vacuum at 50°C for 12 hours. Weigh 40mg Fe 3 o 4 Nano-magnetic beads, dispersed into a Tris (10mmol / L) buffer solution with a pH of 8.5; add 40mg of dopamine under rapid stirring, and the dopamine can be 3 o 4 A thin film was formed on the surface of the nano-magnetic beads independently, and the mixture was stirred rapidly at room temperature for 8 hours. ...

Embodiment 2

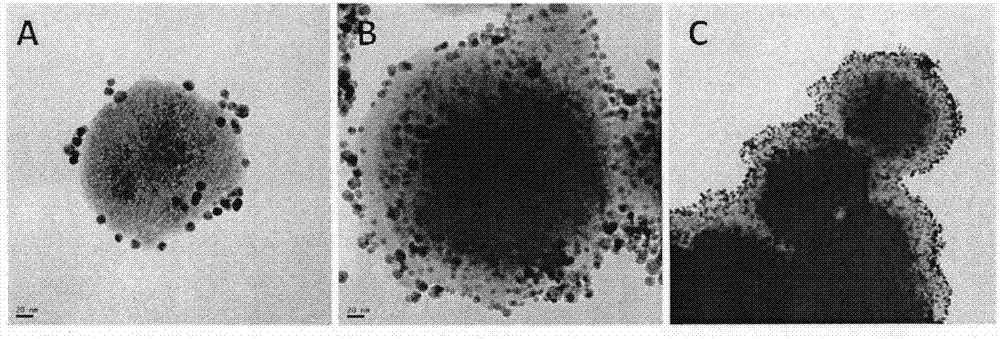

[0037] Weigh 2 mg of Fe with different PDA thicknesses 3 o 4 -PDA nanoparticles were dispersed in 25mL deionized water, ultrasonicated for 5 minutes to form a uniform dispersion, and 75μL 1g / L HAuCl was added under rapid stirring 4 Aqueous solution, after reacting at 90°C for 30 minutes, HAuCl 4 Gold nanoparticles can be formed under the reducing action of dopamine. Then use a magnet to separate, wash with water three times, and dry in vacuum at 50°C for 12 hours to obtain Fe 3 o 4 - Polydopamine-Au nanocomposites.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com