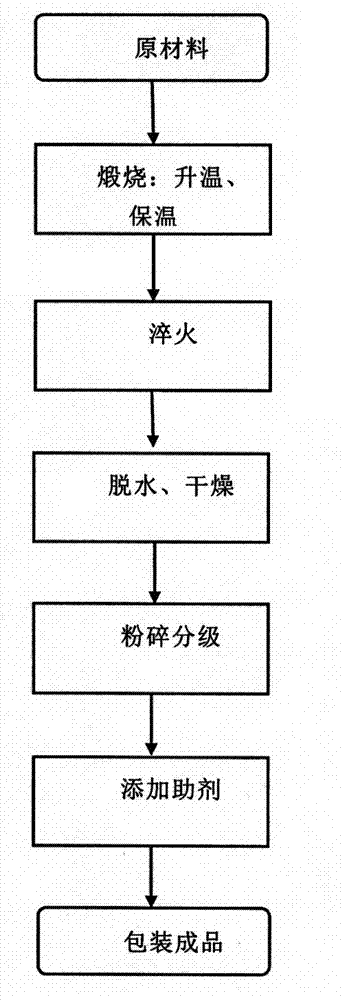

A producing process for preparing cerium oxide polishing powder

A production process and cerium oxide technology are applied in the production process field of preparing cerium oxide polishing powder, which can solve the problems of high cost of raw materials, waste of energy resources, short service life, etc. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] With a purity of 99.95%, a particle size of 8-20μm, and a bulk density of 1.00-1.40g / cm 3 Cerium oxide is used as the raw material. After 120 minutes in the kiln, it is raised to 650°C and held for 80 minutes; then after 90 minutes, it is raised to 950°C and held for 150 minutes; the cerium oxide is quickly poured into cooling water at a temperature of 25°C, and it takes 0.5 min, complete quenching and calcination; dehydration and drying until the moisture content is less than 0.1%; crushing and grading to control the particle size from 2.4 μm to 2.6 μm; adding 0.4% polyethylene glycol 2000 by weight of polishing powder as a dispersant; packaging the finished product.

Embodiment 2

[0040] Using cerium carbonate with a purity of 99.95% as the raw material, heat it up to 650°C in the kiln for 180 minutes, and keep it for 120 minutes; In water, it took 0.5min to complete quenching and calcination; dehydration and drying until the moisture content was less than 0.1%; crushing and grading to control the particle size of 2.4μm-2.6μm; adding 0.5% of the weight of polishing powder polyethylene glycol 2000 as a dispersant; packaging the finished product.

Embodiment 3

[0042] Using cerium oxalate with a purity of 99.95% as the raw material, heat it to 650°C in the kiln for 110 minutes, and keep it for 90 minutes; In water, it took 0.5min to complete quenching and calcination; dehydration and drying until the moisture content was less than 0.1%; crushing and grading to control the particle size of 2.4μm-2.6μm; adding 0.7% of the weight of polishing powder polyethylene glycol 2000 as a dispersant; packaging the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com