Zwitterionic polyester diol and preparation method thereof

A technology of polyester diol and zwitterion, which is applied in the field of polyester diol and its preparation, can solve the problems of single structure and performance, less polyester or polyether polyol, etc., and achieve simplified preparation process and comprehensive performance , good water resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

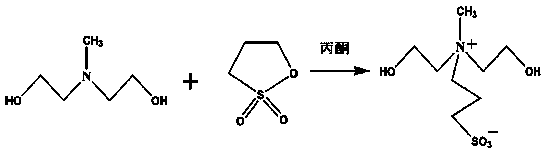

[0033] (1) Preparation of zwitterionic diols by quaternization reaction:

[0034] Dissolve 119g of N-methyldiethanolamine and 122g of 1,3-propane sultone in 200g of acetone, react with stirring at room temperature, and filter to obtain the crude product; wash with acetone to remove unreacted N-methyldiethanolamine in the crude product and 1,3-propane sultone, filtered and dried to obtain a white powder, which is zwitterionic dihydric alcohol; the schematic diagram of its reaction principle is attached figure 1 shown.

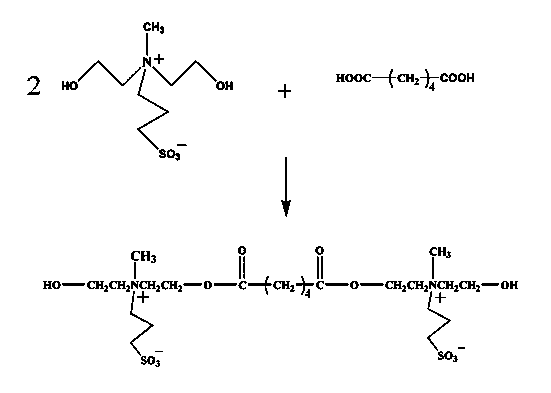

[0035] (2) Esterification to prepare zwitterionic polyester diol:

[0036] First feed nitrogen into the reactor, replace the air in the reactor, add 482g of zwitterionic diols prepared in step (1), 146g of adipic acid and 104g of water, heat, when the temperature in the reactor rises to 80 ℃, keep the temperature constant for 4 hours, and then continue to heat up to 200 ℃ for dehydration reaction; when no reaction-generated water distills out under normal pre...

Embodiment 2

[0040] (1) Preparation of zwitterionic diols by quaternization reaction:

[0041]Dissolve 95.2g of N-methyldiethanolamine and 122g of 1,3-propane sultone in 108g of acetone, react with stirring at room temperature, and filter to obtain the crude product; wash with acetone to remove unreacted N-methyl di Ethanolamine and 1,3-propane sultone are filtered and dried to obtain a white powder, which is zwitterionic diol.

[0042] (2) Esterification to prepare zwitterionic polyester diol:

[0043] First feed nitrogen into the reactor, replace the air in the reactor, add 482g of zwitterionic diols prepared in step (1), 90g of oxalic acid and 276g of water, heat, when the temperature in the reactor rises to 70 ℃, keep the temperature constant for 8 hours, and then continue to heat up to 190 ℃ for dehydration reaction; when no reaction-generated water distills out under normal pressure, add the catalyst dibutyltin dilaurate (control the ratio of the catalyst content in the system to 40...

Embodiment 3

[0047] (1) Preparation of zwitterionic diols by quaternization reaction:

[0048] Dissolve 142.8g of N-methyldiethanolamine and 122g of 1,3-propane sultone in 434g of acetone, react with stirring at room temperature, and filter to obtain the crude product; wash with acetone to remove unreacted N-methyl di Ethanolamine and 1,3-propane sultone are filtered and dried to obtain a white powder, which is zwitterionic diol.

[0049] (2) Esterification to prepare zwitterionic polyester diol:

[0050] First feed nitrogen into the reactor, replace the air in the reactor, add 482g of zwitterionic diols prepared in step (1), 148g of phthalic anhydride and 30.5g of water, heat, when the temperature in the reactor When the temperature rises to 70°C, keep the temperature constant for 8 hours, and then continue to heat up to 200°C for dehydration reaction; when no reaction-generated water distills out under normal pressure, add catalyst p-toluenesulfonic acid (control the ratio of catalyst c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com