Bio-based carbon nano dot fluorescent powder, preparation method and applications thereof

A bio-based carbon and carbon nanodot technology, applied in the field of nanomaterials, can solve the problems of low luminous quantum efficiency and intractability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

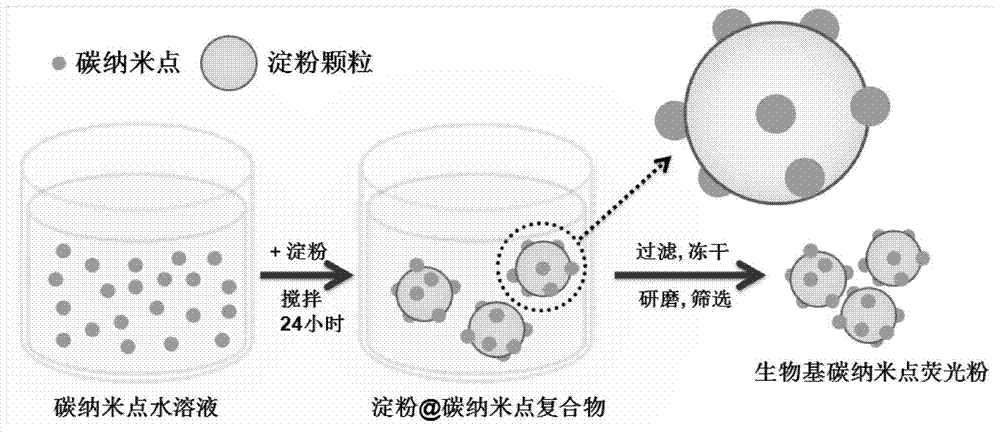

[0044] The present invention also provides a preparation method of the above-mentioned bio-based carbon nano-dot fluorescent powder, comprising the following steps:

[0045] ① Mix and dissolve carbon nanodots and biological product powder in water, and keep stirring to obtain a reaction mixture;

[0046] ② The reaction mixture obtained in ① is filtered, freeze-dried, ground, and screened to obtain bio-based carbon nano-dot phosphors.

[0047] The mass ratio of carbon nanodots and biological product powder in the present invention is preferably 1:(20-450), the stirring temperature is preferably room temperature, and the stirring time is preferably 12-24 hours.

[0048] The purpose of filtering the reaction mixture in the present invention is to separate the carbon nano-dots that are not adsorbed on the surface of the starch granules. The freeze-drying is preferably carried out in a vacuum freeze-drying machine, and the freeze-drying temperature is preferably -45~-55°C. The fre...

Embodiment 1

[0055] Dissolving the carbon nano-dots and starch emitting green light in water at a mass ratio of 1:20, and continuously stirring at room temperature for 24 hours to obtain a reaction mixture;

[0056] Filter the above reaction mixture through qualitative filter paper to separate the carbon nano-dots that are not adsorbed on the surface of the starch granules to obtain the filtrate, freeze-dry the filtrate through a vacuum freeze dryer at minus 50 degrees for 24 hours, and then fully grind into powder, and screened through a 400-mesh fine sieve to obtain bio-based carbon nano-dot fluorescent powder with uniform particle size.

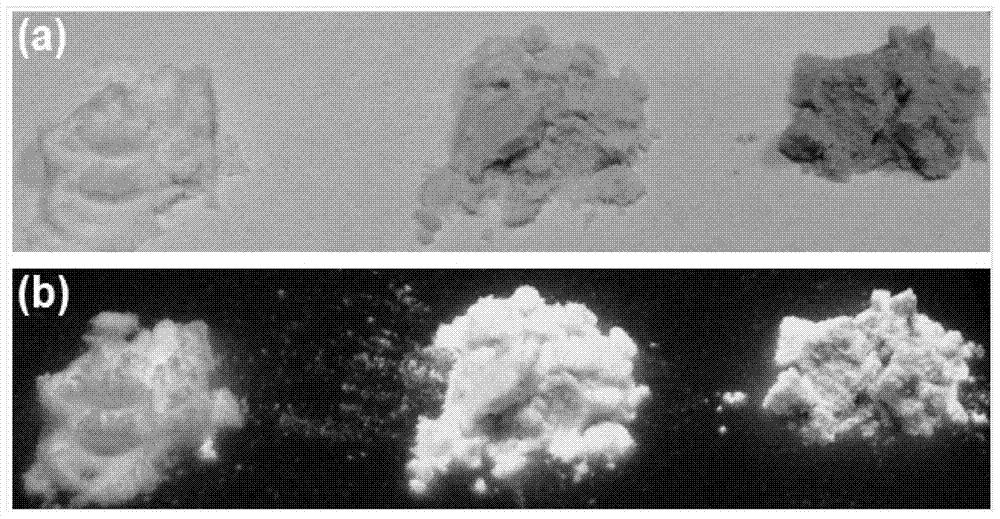

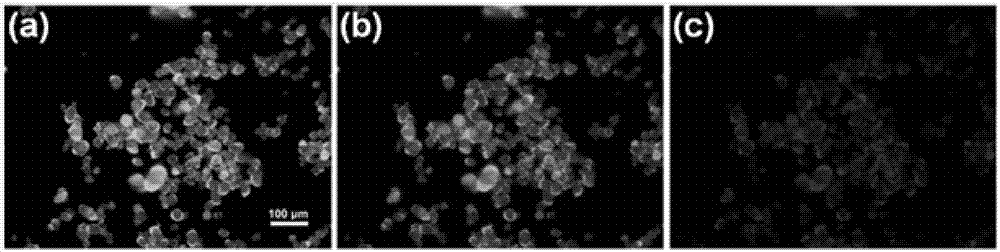

[0057] figure 1 It is a schematic diagram of the preparation method of bio-based carbon nano-dot fluorescent powder in Example 1 of the present invention. The selected biological product powder is starch. It can be adsorbed on the surface of starch granules through hydrogen bonds to achieve effective dispersion and efficient luminescence of carbon nan...

Embodiment 2

[0059] Dissolving the carbon nano-dots and starch emitting green light in water at a mass ratio of 1:45, and continuously stirring at room temperature for 24 hours to obtain a reaction mixture;

[0060] Filter the above reaction mixture through qualitative filter paper to separate the carbon nano-dots that are not adsorbed on the surface of the starch granules to obtain the filtrate, freeze-dry the filtrate through a vacuum freeze dryer at minus 50 degrees for 24 hours, and then fully grind into powder, and screened through a 400-mesh fine sieve to obtain bio-based carbon nano-dot fluorescent powder with uniform particle size.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com