Preparation method and application of a kind of activated carbon modified material

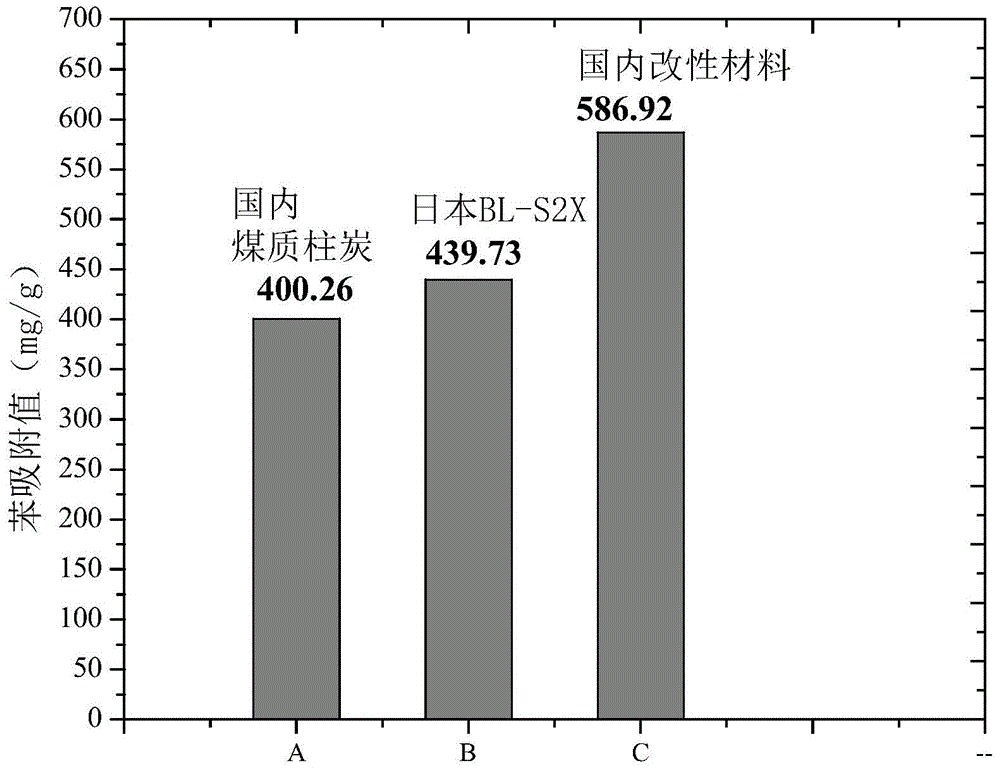

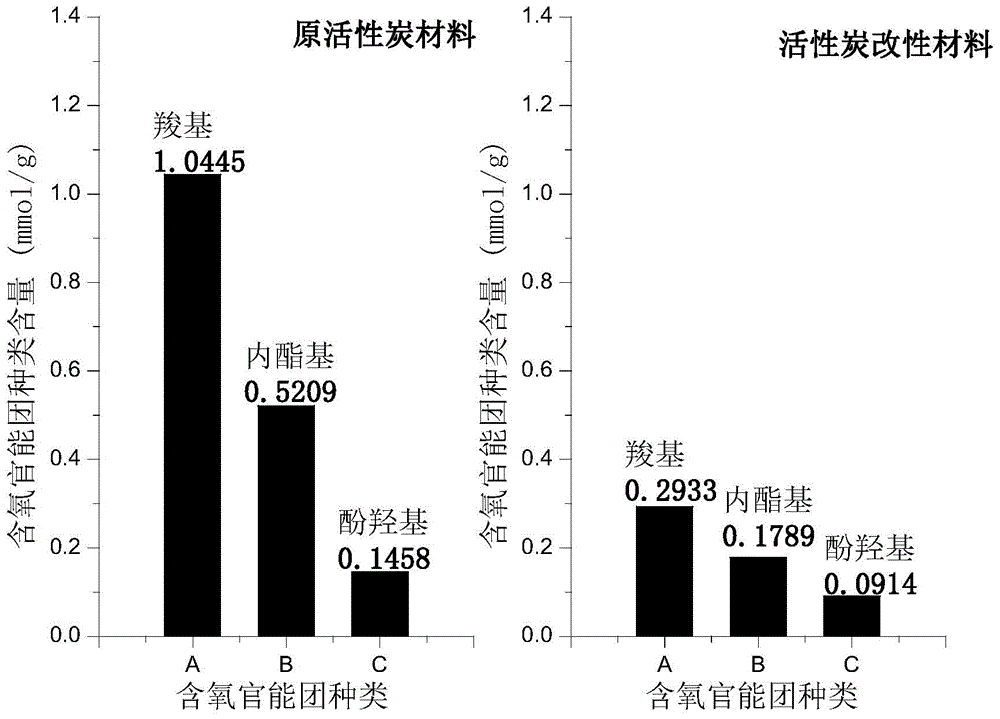

A modified material and activated carbon technology, applied in the preparation of halogenated hydrocarbons, chemical instruments and methods, organic chemistry, etc., can solve the problems of small adsorption capacity of dichloromethane, weakened adsorption performance, poor adsorption selectivity, etc. The effect of reducing groups, maintaining stable adsorption capacity, and high adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

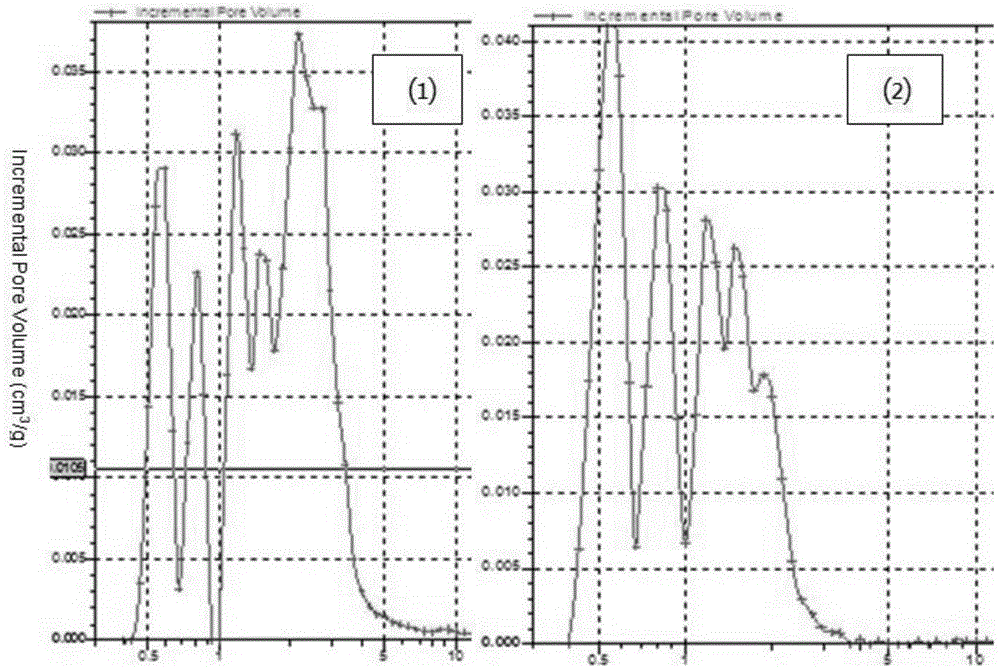

Method used

Image

Examples

Embodiment 1

[0027] A preparation method of activated carbon modified material, comprising the following steps:

[0028] The first step is the pretreatment of activated carbon. With a specific surface area of 1200m 2 / g of coal-based columnar activated carbon (HZ-8040, Ningxia Guanghua Qisi Activated Carbon Co., Ltd., Ф2-3mm) is used as the modified raw material, first impregnated with 1mol / L sodium hydroxide solution and shaken for 12h, then filtered and washed Until the filtrate is neutral, then immerse and vibrate with 3.83wt% hydrochloric acid solution for 12 hours, filter, wash until the filtrate is neutral, put the sample into a beaker, add an appropriate amount of deionized water, and then place it in an ultrasonic instrument with a power of 700W for 30 minutes , filtered and dried in a drying oven at 120°C for 24 hours, and finally the pretreated sample was stored in a desiccator for future use.

[0029] The second step is the physical and chemical modification of activated car...

Embodiment 2

[0031] A preparation method of activated carbon modified material, comprising the following steps:

[0032] The first step is the pretreatment of activated carbon. Coal-based columnar activated carbon (HZ-8040, Ningxia Guanghua Qisi Activated Carbon Co., Ltd., Ф2-3mm) with a specific surface area of 1200m2 / g was used as the modified raw material, and the sodium hydroxide solution with a concentration of 2mol / L was first impregnated and shaken for 10h , then filter, wash until the filtrate is neutral, then immerse and vibrate with 5wt% hydrochloric acid solution for 10h, filter, wash until the filtrate is neutral, put the sample into a beaker, add an appropriate amount of deionized water, and then place it in an ultrasonic wave with a power of 1000W Wash in the instrument for 30 minutes, filter and dry in a 100°C drying oven for 24 hours, and finally store the pretreated sample in a desiccator for future use.

[0033] The second step is the physical and chemical modification...

Embodiment 3

[0035] A preparation method of activated carbon modified material, comprising the following steps:

[0036] The first step is the pretreatment of activated carbon. With a specific surface area of 1500m 2 / g Coconut shell columnar activated carbon (BL-S2X, Osaka Gas Co., Ltd., Japan, Ф2-3mm) is used as the modified raw material and is impregnated and shaken for 12 hours in a sodium hydroxide solution with a concentration of 1mol / L, then filtered and washed until the filtrate If it is neutral, then immerse and shake it with 3.83wt% hydrochloric acid solution for 12 hours, filter, wash until the filtrate is neutral, put the sample into a beaker, add an appropriate amount of deionized water, and then place it in an ultrasonic instrument with a power of 700W for 60 minutes, filter After that, it was dried in a drying oven at 120°C for 24 hours, and finally the pretreated sample was stored in a desiccator for future use.

[0037] The second step is the physical and chemical modifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| adsorption temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com