Bombax ceiba fiber-base adsorption catalysis material

A technology of kapok fiber, adsorption and catalysis, applied in the direction of adsorption of water/sewage treatment, physical/chemical process catalyst, organic compound/hydride/coordination complex catalyst, etc. Simple, mild reaction conditions, and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

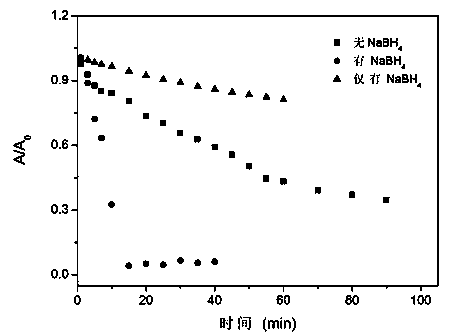

Embodiment 1

[0019] In 500 mL of 1 mol / L hydrochloric acid solution, add 10 grams of aniline and 20 grams of kapok fiber, and stir for 2 hours to obtain a reaction solution; add 20 grams of initiator silver perchlorate to the above reaction solution, and stir at normal temperature and pressure to react After 12 hours, separate the obtained solid; wash the solid with water, adjust the pH to 6-7, wash with water and ethanol, and dry at 50°C to obtain a kapok fiber-based adsorption catalytic material. The product can achieve complete adsorption and catalysis of 10 mg / L methylene blue within 30 minutes.

Embodiment 2

[0021] In 500 mL of 2 mol / L nitric acid solution, add 20 grams of aniline and 20 grams of kapok fiber, and stir for 3 hours to obtain a reaction solution; add 10 grams of initiator silver nitrate and 20 grams of hydrogen peroxide into the above reaction solution, and heat at normal temperature and pressure Stirring and reacting for 24 hours, separating the obtained solid; washing the solid with water, adjusting the pH to 6-7, washing with water and ethanol, and drying at 60°C to obtain a kapok fiber-based adsorption catalytic material. The product can achieve complete adsorption and catalysis of 10 mg / L methylene blue within 30 minutes.

Embodiment 3

[0023] In 500 mL of 3 mol / L acetic acid solution, add 15 grams of aniline and 30 grams of kapok fiber, and stir for 1 hour to obtain a reaction solution; 15 grams of initiator silver perchlorate and 25 grams of ammonium persulfate are added to the above reaction solution , stirred and reacted at normal temperature and pressure for 36 hours, and the obtained solid was separated; after the solid was washed with water, the pH was adjusted to 6~7, and after being washed with water and ethanol, it was dried at room temperature at 20°C to obtain a kapok fiber-based adsorption catalyst Material. The product can achieve complete adsorption and catalysis of 10 mg / L methylene blue within 30 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com