Ferroferric oxide/carbon/cadmium sulfide composite nano material and preparation method thereof

A technology of composite nanomaterials and ferroferric oxide, which is applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the complicated process, uneven shape and size of composite materials, and poor dispersion and other problems, to achieve the effect of simple process, suitable size and strong magnetism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

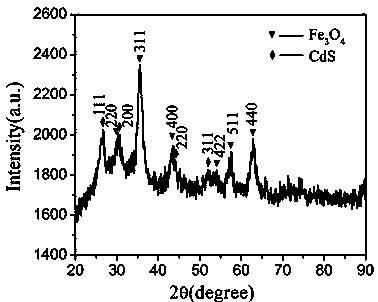

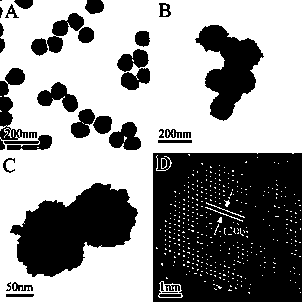

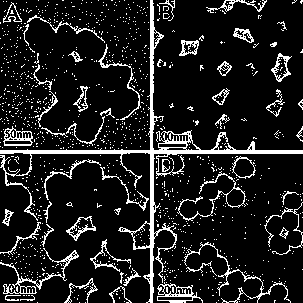

[0028] The invention provides a preparation method of ferric oxide / carbon / cadmium sulfide composite nanomaterial, comprising the following steps:

[0029] Step A: Add ferrocene to acetone, stir ultrasonically to form a mixed solution, then add hydrogen peroxide dropwise to the mixed solution, stir and transfer to an autoclave and heat, centrifugally clean, and disperse into ethanol to form Fe 3 o 4 C nanoparticle, means coating;

[0030] Step B: cadmium nitrate is added to ethanol and water to form a transparent solution, and the Fe 3 o 4 C nanoparticles were added into the transparent solution, ultrasonically dispersed, heated in a water bath and then centrifugally cleaned to form Fe 3 o 4 CCd 2+ Nanoparticles, meaning encapsulation;

[0031] Step C: the Fe 3 o 4 CCd 2+ Nanoparticles, thioacetamide and water are mixed, microwaved after stirring, centrifugally cleaned, dried and milled to form ferric oxide / carbon / cadmium sulfide composite nanometer material.

[0032]...

Embodiment 1

[0041] The preparation method of ferric oxide / carbon / cadmium sulfide composite nanomaterial comprises the following steps:

[0042] A. With ferric oxide nanocrystals as the core, a carbon shell is coated on its surface:

[0043] a. Add 0.6 grams of ferrocene to 30 milliliters of acetone, and ultrasonically disperse for 10 minutes to form a homogeneous mixture;

[0044] b. Add 3mL hydrogen peroxide dropwise to the mixture formed in the previous step, and stir evenly;

[0045] c. Transfer the mixed solution formed in the previous step into a 50 ml autoclave and put it into an oven to keep heating at 210 degrees Celsius for one day;

[0046] d. Centrifuge the mixed solution formed in the previous step, and then disperse it in 6 ml of ethanol to form Fe 3 o 4 C nanoparticle, means coating;

[0047] B. Uniformly wrap cadmium sulfide nanoparticles on the surface of the carbon layer:

[0048] e. Add 0.01 mmol (3.0847 grams) of cadmium nitrate to 9 milliliters of ethanol and 10...

Embodiment 2

[0055] On the basis of Example 1, change the hydrogen peroxide in step b in A to 0.5 ml.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com