Method for surface nano-crystallization and structure stabilization of metal material

A metal material, nanotechnology, applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve problems such as grain growth, achieve stable surface performance, low energy consumption, and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) The pure copper sheet is used for stress relief annealing treatment. The length, width and thickness of the sheet are 100 mm × 100 mm × 10 mm, the annealing temperature is 250 °C, and the holding time is 0.5 h to remove the residual internal stress in the previous machining. ;

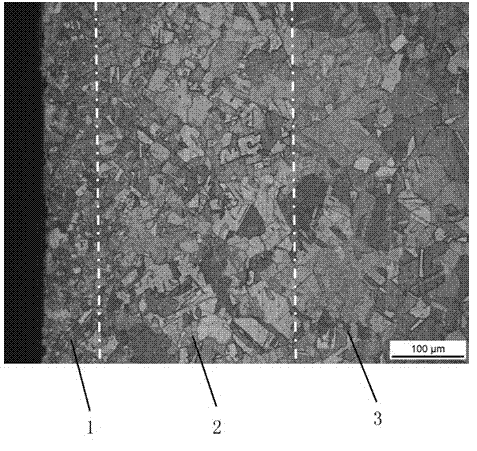

[0027] (2) Fix the pretreated pure copper sheet on the top of the grinding tank of the surface mechanical attrition treatment (SMAT for short), the tank is in a vacuum state, and a large number of steel balls are installed. The material of the steel balls is GCr15, The diameter of the steel ball is 12 mm; when the machine is started, the surface of the material is repeatedly hit with high frequency to carry out surface grinding treatment. The surface nanoization treatment time is 30 minutes, and the vibration frequency of the system is 100 Hz; side organization as figure 1 As shown in the figure, 1 is the surface nanocrystalline layer of copper, 2 is the fine-grained and ultra-fine-grained ...

Embodiment 2

[0032] (1) Use pure copper sheet for stress relief annealing, the length, width and thickness of the sheet are 50 mm × 50 mm × 2 mm, the annealing temperature is 200 °C, and the holding time is 5 h to remove the residual internal stress in the previous machining;

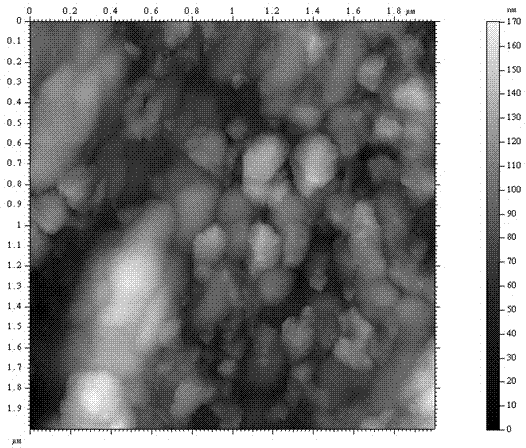

[0033] (2) Fix the pretreated copper plate sample on the top of the grinding tank with surface mechanical attrition treatment (SMAT for short), the tank is in an argon atmosphere, and a large number of steel balls are installed, and the material of the steel balls is GCr15 , the diameter of the steel ball is 8 mm. When the machine is started, the surface of the material is repeatedly hit with high frequency to carry out surface grinding treatment. The surface nanoization treatment time is 90 min, and the system vibration frequency is 50 Hz; The average grain size of the nanocrystalline layer is about 60 nm, and the layer thickness is about 55 μm.

[0034] (3) Perform stress relief annealing on the surface mechanical...

Embodiment 3

[0038] (1) The pure copper sheet is used for stress relief annealing treatment. The length, width and thickness of the sheet are 60 mm × 70 mm × 4 mm, the annealing temperature is 180 °C, and the holding time is 10 h to remove the residual internal stress in the previous machining. ;

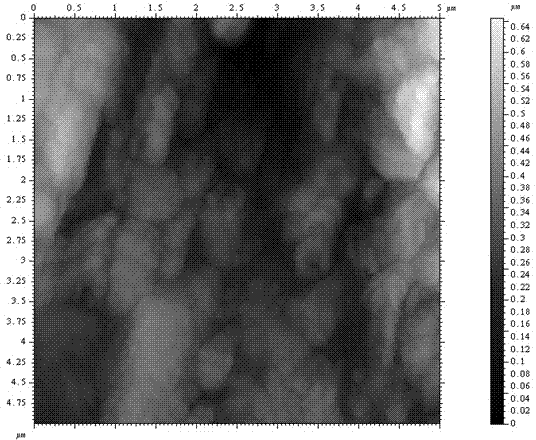

[0039] (2) Fix the pretreated copper plate sample on the top of the grinding tank with surface mechanical attrition treatment (SMAT for short), the tank is in a vacuum state, and a large number of steel balls are installed. The material of the steel balls is GCr15, The diameter of the steel ball is 4 mm. When the machine is started, the surface of the material is repeatedly hit with high frequency to carry out surface grinding treatment. The surface nanoization treatment time is 180 min, and the system vibration frequency is 20 Hz; The average grain size is about 70 nm, and the nanolayer thickness is about 45 μm;

[0040] (3) Perform stress relief annealing on the surface mechanically ground pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com