Preparation method of elastic porous chitosan sponge

A technology of porous chitosan and chitosan, which is applied in the field of preparation of porous chitosan sponge, can solve the problems of narrow application and high price of cross-linking agent genipin, so as to avoid collapse, ensure biological safety, and wide The effect of applying the foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

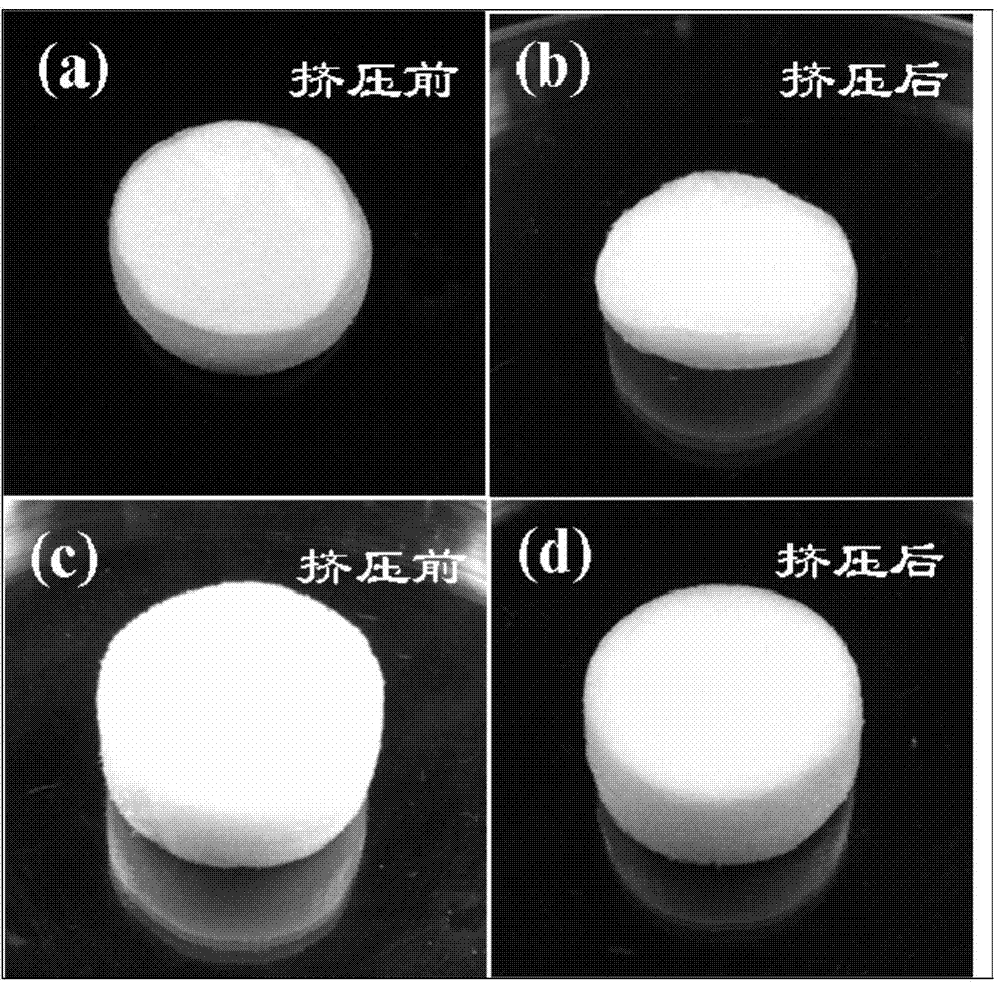

[0021] Embodiment 1: the preparation of elastic porous chitosan sponge

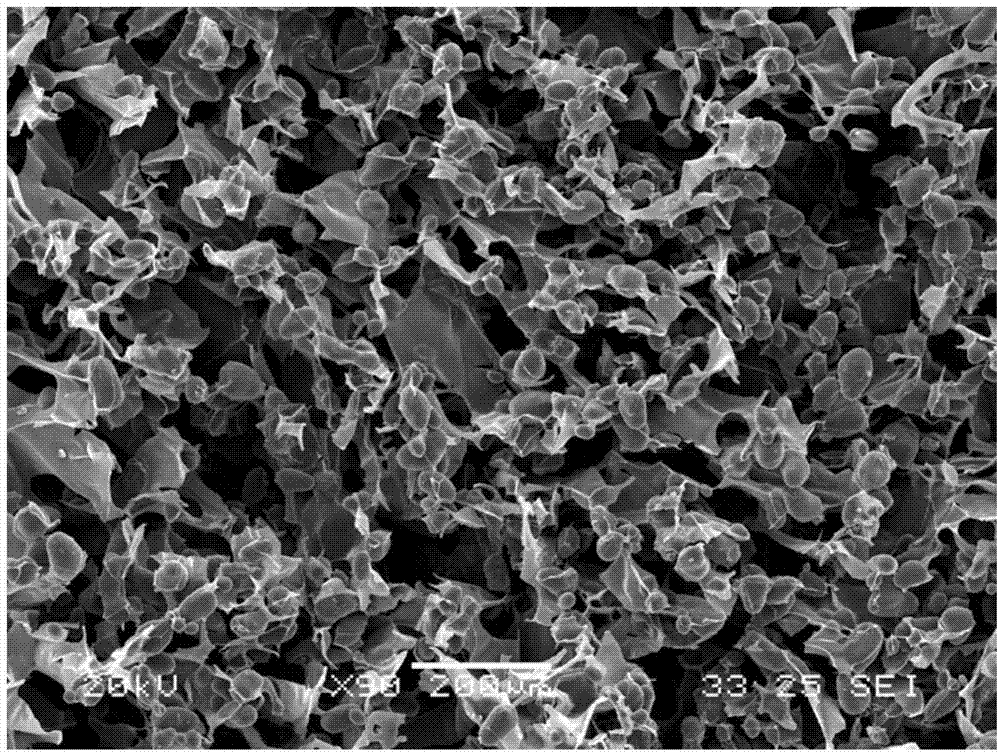

[0022] Weigh 1.0 g of chitosan powder, wherein the degree of deacetylation of chitosan is 98%, and the viscosity is 100 cp·s. Chitosan was dissolved in 50 mL of 1% (v / v) acetic acid to prepare a 2.0% (w / v) chitosan solution. Then pour it into a twelve-well culture plate and pre-freeze it in a -20°C refrigerator. Place the frozen chitosan solution in a vacuum freeze dryer for 24 hours to freeze-dry, wherein the parameters of the freeze dryer are: cold trap temperature<-52°C, vacuum degree<10Pa.

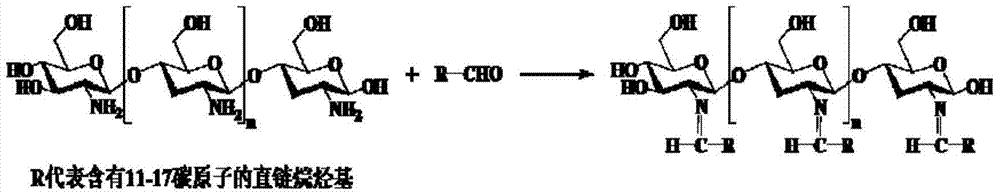

[0023] Use a pipette gun to pipette 700 μL of dodecanal, dissolve it in 30 mL of absolute ethanol, and sonicate until the dodecanal is completely dissolved to obtain a 0.2 mol / L clear and transparent cross-linking agent solution. The blank chitosan sponge was taken out from the 12-well culture plate, and soaked in the cross-linking agent solution, the soaking temperature was 70°C, and the soaking time was 8 hour...

Embodiment 2

[0025] Embodiment 2: the preparation of elastic porous chitosan sponge

[0026] Weigh 0.5 g of chitosan, wherein the degree of deacetylation of chitosan is 98%, and the viscosity is 200 cp·s. Chitosan was dissolved in 50 mL of 1% (v / v) acetic acid to prepare a 1.0% (w / v) chitosan solution. Then pour it into a twelve-well culture plate and pre-freeze it in a -20°C refrigerator. Place the frozen chitosan solution in a vacuum freeze dryer for 18 hours to freeze-dry, wherein the parameters of the freeze dryer are: cold trap temperature<-52°C, vacuum degree<10Pa.

[0027] Use a pipette gun to pipette 400 μL of tetradecaldehyde, dissolve it in 30 mL of absolute ethanol, and sonicate until the tetradecaldehyde is completely dissolved to obtain a clear and transparent cross-linking agent solution of 0.07 mol / L. Take the blank chitosan sponge out of the 12-well culture plate, put it into the cross-linking agent solution and soak it, the soaking temperature is 75°C, and the soaking ti...

Embodiment 3

[0028] Embodiment 3: the preparation of porous chitosan sponge with elasticity

[0029]Weigh 1 g of chitosan, wherein the degree of deacetylation of the chitosan is 70%, and the viscosity is 150 cp·s. Chitosan was dissolved in 50 mL of 1% (v / v) acetic acid to prepare a 2.0% (w / v) chitosan solution. Then pour it into a twelve-well culture plate and pre-freeze it in a -18°C refrigerator. Place the frozen chitosan solution in a vacuum freeze dryer for 20 hours to freeze-dry, wherein the parameters of the freeze dryer are: cold trap temperature<-52°C, vacuum degree<10Pa.

[0030] Use a pipette gun to pipette 300 μL of octadecaldehyde, dissolve it in 30 mL of absolute ethanol, and sonicate until octadecaldehyde is completely dissolved to obtain a 0.04 mol / L clear and transparent cross-linking agent solution. The blank chitosan sponge was taken out from the 12-well culture plate, and soaked in the cross-linking agent solution, the soaking temperature was 60° C., and the soaking ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com