Preparing method of sea-urchin-shaped amorphous Ni-B alloy nanometer materials

An alloy nanomaterial, amorphous technology, applied in the field of Ni-B alloy nanomaterials, can solve the problems of low performance, reduction of Ni cations, low specific surface area, etc., and achieve the effect of high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] In order to achieve the above object, the preparation steps of concrete Ni-B amorphous sea urchin are:

[0039] 1) 40mL NH 3 h 2 O solution (25%) was mixed with 10 mL of nickel chloride (0.0085 mol) to form Ni(NH 3 ) 6 2+ mixed solution;

[0040] 2) At 298K temperature, 32mL KBH 4 Aqueous solution (1.0M) and PVA0.001M were added under argon atmosphere;

[0041] 3) The prepared product was obtained after liquid phase plasma technology treatment for 5 minutes;

[0042] 4) Wash it once with deionized water, and then wash it three times with absolute ethanol;

[0043] 5) Store samples in ethanol until use.

Embodiment 2

[0045] 1) 40mL NH 3 h 2 O solution (25%) was mixed with 10 mL of nickel chloride (0.0085 mol) to form Ni(NH 3 ) 6 2+ mixed solution;

[0046] 2) At 298K temperature, 32mL KBH 4 Aqueous solution (1.0M) and PVA0.002M were added under argon atmosphere;

[0047] 3) The prepared product was obtained after liquid phase plasma technology treatment for 5 minutes;

[0048] 4) Wash it once with deionized water, and then wash it three times with absolute ethanol;

[0049] 5) Store samples in ethanol until use.

Embodiment 3

[0051] 1) 40mL NH 3 h 2 O solution (25%) was mixed with 10 mL of nickel chloride (0.0085 mol) to form Ni(NH 3 ) 6 2+ mixed solution;

[0052] 2) At 298K temperature, 32mL KBH 4 Aqueous solution (1.0M) and PVA0.003M were added under argon atmosphere;

[0053] 3) The prepared product was obtained after liquid phase plasma technology treatment for 5 minutes;

[0054]4) Wash it once with deionized water, and then wash it three times with absolute ethanol;

[0055] 5) Store samples in ethanol until use.

[0056] The performance of sea urchin shape amorphous Ni-B alloy nano material of the present invention:

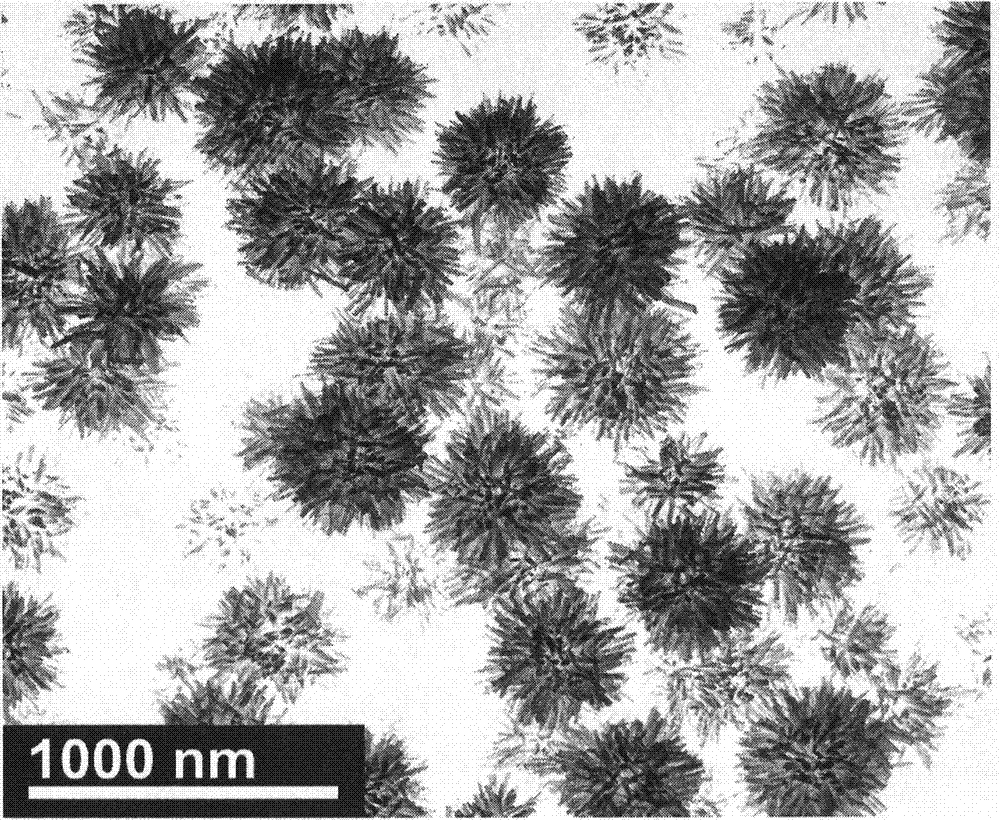

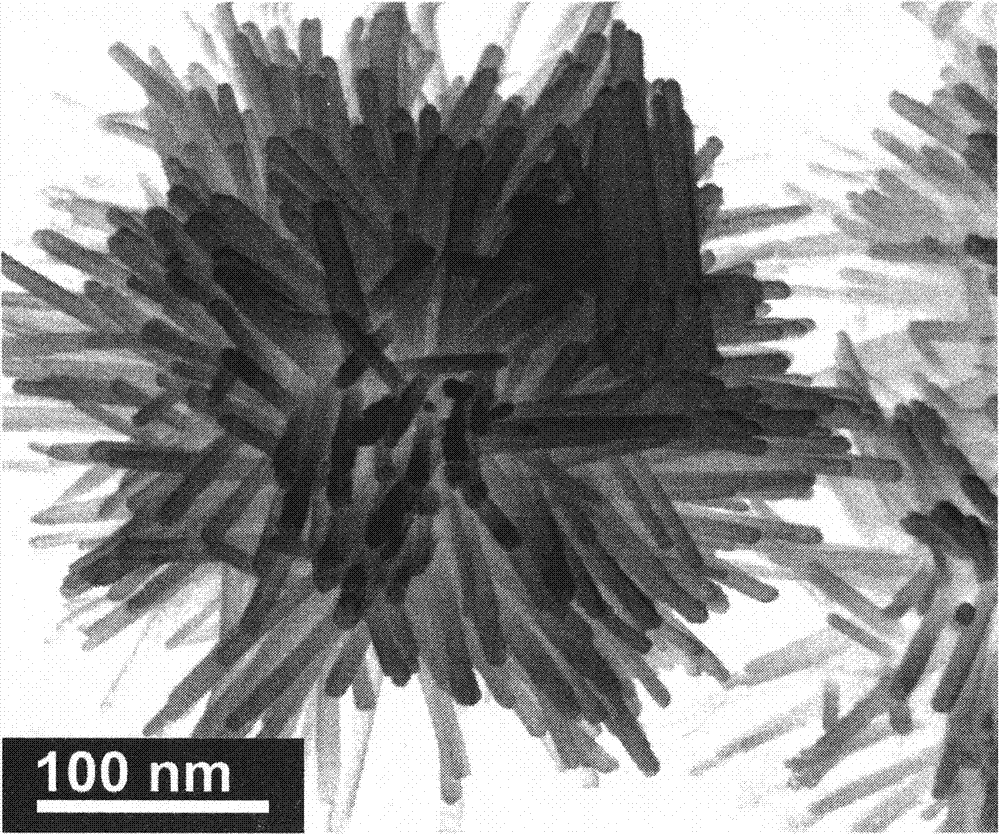

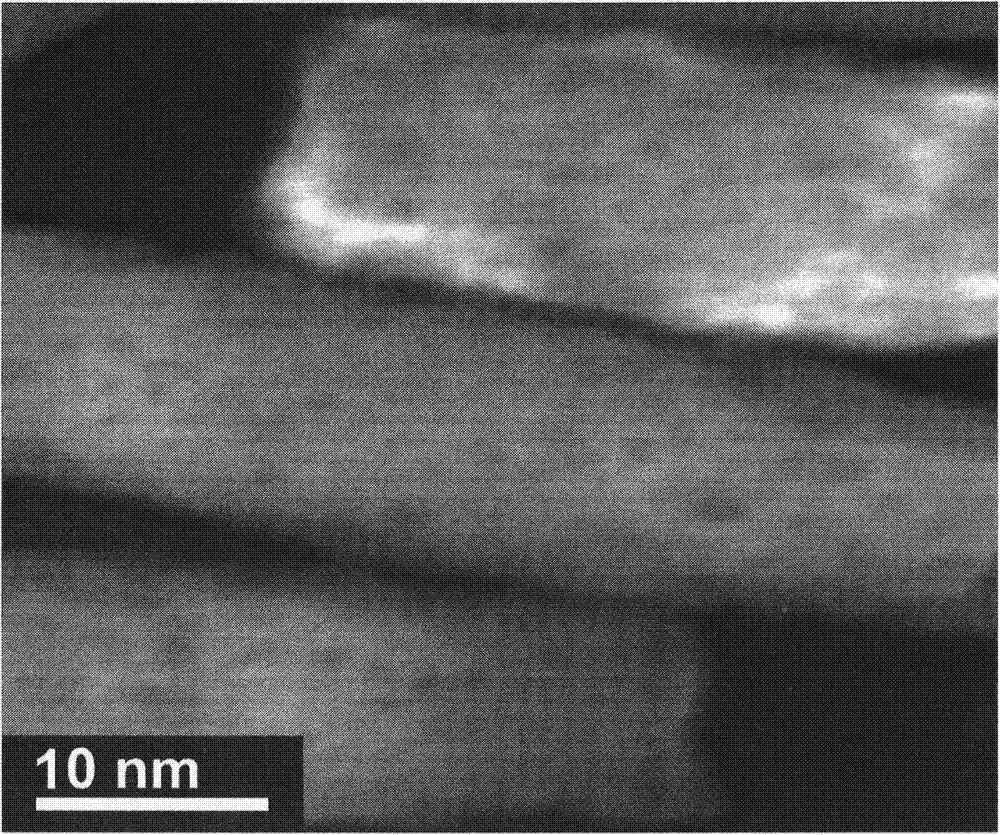

[0057] The material prepared in Example 1 was characterized by STEM, figure 1 It is a low-magnification STEM image of the sample. It can be seen that the sea urchin-like Ni-B particles have been successfully prepared with an average particle size of about 240nm, and they are assembled from nanorods ( figure 2 ). High-resolution STEM images reveal that nanorods make...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com