Biological organic fertilizer produced by energy-saving tubular microporous aerated fermentation and method thereof

A bio-organic fertilizer and production method technology, applied in the field of fertilizers, can solve the problems of high energy consumption of aeration and fermentation, long production cycle, low granulation rate, etc., and achieve the effects of improving aggregate structure, improving soil, and breaking hardening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

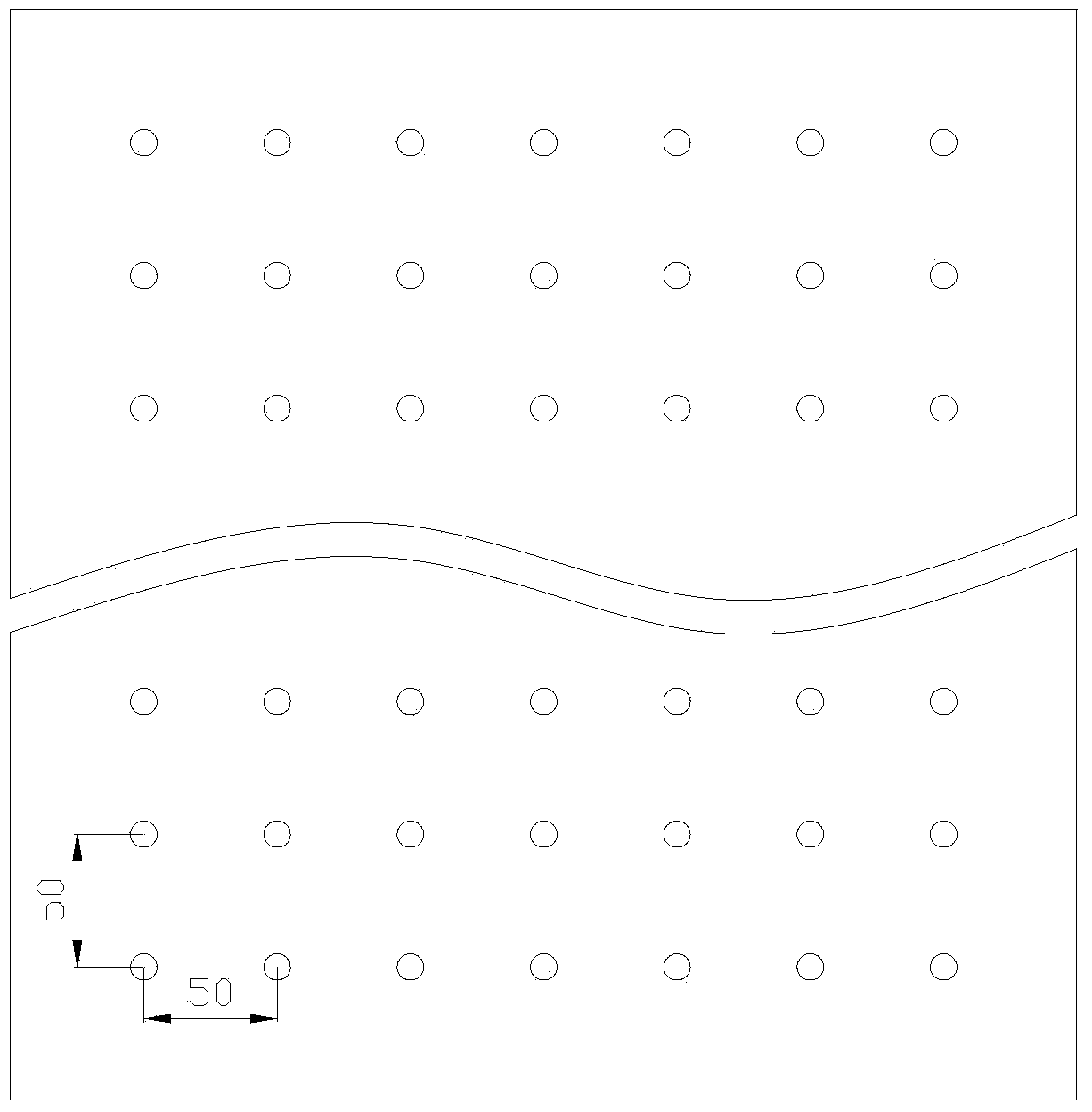

[0067] Embodiment 1, the making of energy-saving microporous tube such as Figure 5 ;

[0068] 1. Use a PVC pipe with a nominal outer diameter of 50mm and a wall thickness of 2.0mm to take a length of 1.33M;

[0069] 2. Drill a hole with a diameter of 4-5mm on the pipe at an interval of 4-5cm, and the upper and lower adjacent holes should be staggered;

[0070] Invention principle: The oxygen required for fermentation is supplied through the gaps of the fermentation raw material particles. The use of the energy-saving microporous tube can effectively increase the porosity and pore size. Relying on natural ventilation, the energy-saving effect is obvious, and at the same time it is conducive to ventilation and oxygen supply, thus greatly Shorten the fermentation time and reduce turning over.

Embodiment 2

[0071] Embodiment 2, according to image 3 , Figure 4 The energy-saving microporous tube made in Example 1 is placed vertically in the fermenter as shown;

[0072] Fermentation tank according to image 3 , Figure 4 When the spacing shown is constructed, a hole with a depth of 5 cm and a diameter slightly larger than 5 cm is arranged at the bottom of the fermentation tank for placing the energy-saving microporous tube described in Example 1.

Embodiment 3

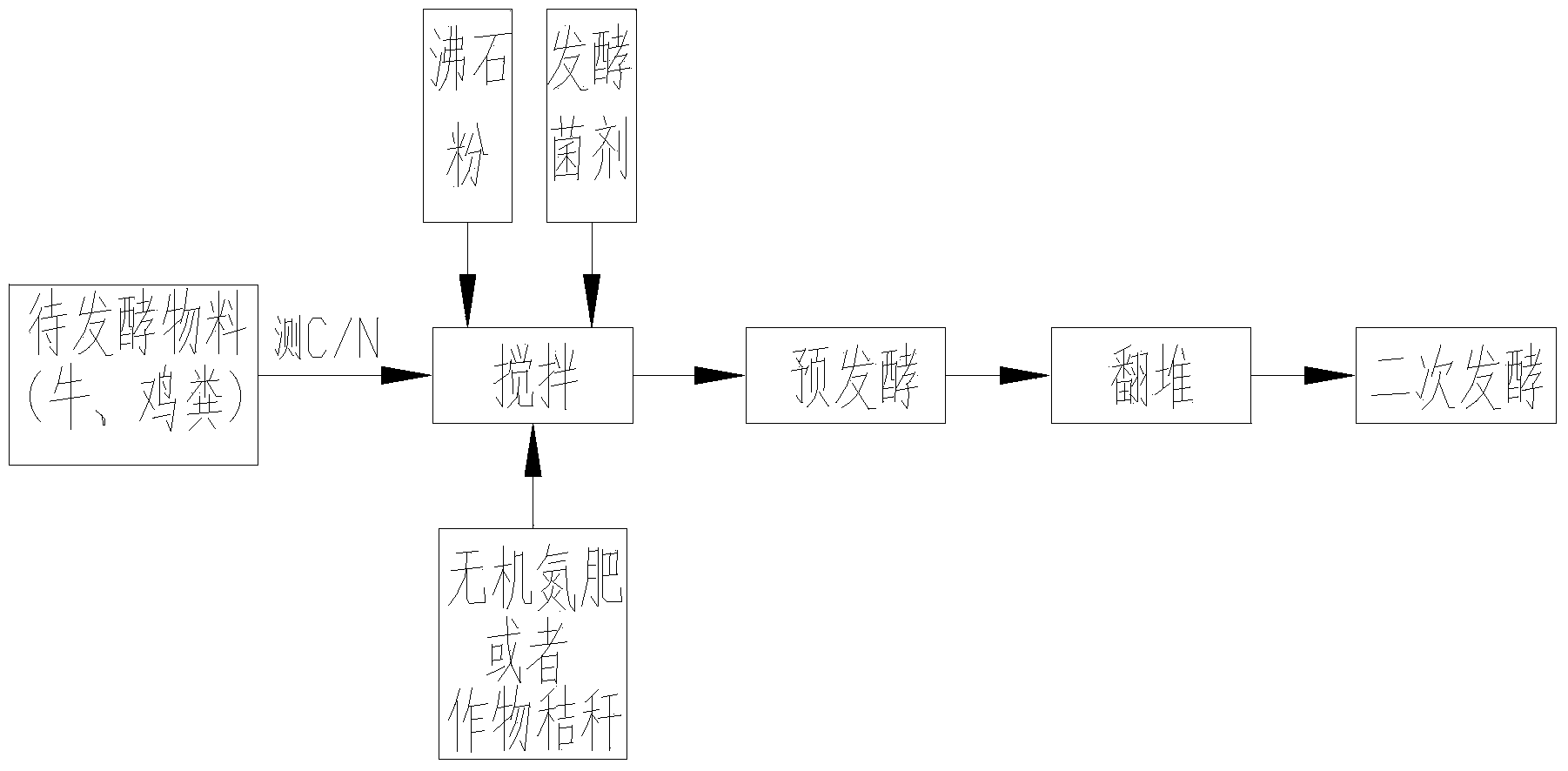

[0073] Embodiment 3, preparation raw material carries out fermentation

[0074] 1) Prepare the cow dung, chicken manure, zeolite powder, fermenting agent, inorganic nitrogen fertilizer (ammonium sulfate or urea), and crushed crop straw to be fermented.

[0075] 2) One ton of cow dung and chicken dung needs about 3-3.5m 3 , zeolite powder about 30-50kg, fermented bacteria agent, depending on the season and other conditions, according to 3-5kg / m 3 Add, put into a blender and stir evenly; detect the C / N ratio of the mixture;

[0076] 3) Add inorganic nitrogen fertilizer, ammonium sulfate 12-15kg or urea 5.3-8kg or crushed crop stalks to the mixed species to adjust the C / N of the mixture until the C / N is 25%-28%.

[0077] 4) Place the C / N mixture adjusted in 3) in the fermenter arranged in Example 2 for pre-fermentation.

[0078] 5) When the temperature in the pre-fermentation tank reaches 60°C-65°C, turn the fermented product into the adjacent fermentation tank for the second ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com