Preparation method of polyisoprene rubber latex

A technology of polyisoprene and isoprene rubber, which is applied in the field of synthetic latex preparation, can solve problems affecting the use of latex, and achieve the effects of reducing emissions and high mechanical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

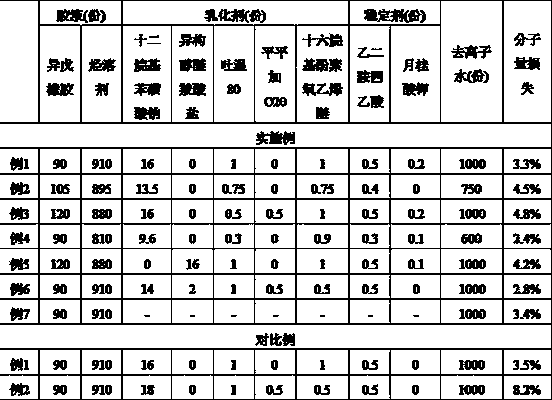

Examples

Embodiment 1

[0028] Get isoprene rubber concentration and be 1000 parts of glue solution of 9.0%, join in 1000 parts of emulsifier aqueous solution, wherein emulsifier concentration is 1.8%, regulate the pH value of emulsifier aqueous solution with potassium hydroxide or potassium dihydrogen phosphate. Premixed by strong mechanical stirring for 15 minutes, then transferred to an emulsification tank, sheared and emulsified by a shear for 15 minutes, with a linear velocity of 5.4 m / s, to obtain an O / W emulsion. Pumped into the evaporator for vacuum distillation to remove the hydrocarbon solvent, wherein the temperature of the emulsion is 65°C, the vacuum in the evaporator is 55 kPa, and the vacuum distillation is stopped after 70 minutes. The residual value of the hydrocarbon solvent in the emulsion is determined to be 760 ppm. Then pump it into the vacuum membrane distillation device to further remove the hydrocarbon solvent, in which the feed liquid, that is, the emulsion flows through the ...

Embodiment 2

[0032]Get isoprene rubber concentration and be 1000 parts of glue solution of 10.5%, join in 750 parts of emulsifier aqueous solution, wherein emulsifier concentration is 2.0%, regulate the pH value of emulsifier aqueous solution with potassium hydroxide or potassium dihydrogen phosphate. It was pre-mixed by strong mechanical stirring for 20 min, then transferred to an emulsification tank, and emulsified by shearing machine for 15 min at a line speed of 8.7 m / s to obtain an O / W emulsion. Pump it into the evaporator for desolvation by vacuum distillation. The temperature of the emulsion is 65°C, the vacuum in the evaporator is 55 kPa, and the vacuum distillation stops after 70 minutes. The residual value of hydrocarbon solvent in the emulsion is determined to be 720 ppm. It is then pumped into a vacuum membrane distillation device to further remove the hydrocarbon solvent, wherein the feed liquid, that is, the emulsion flows through the tube side of the membrane module, and the ...

Embodiment 3

[0035] Get isoprene rubber concentration and be 1000 parts of glue solution of 12.0%, join in 1000 parts of emulsifier aqueous solution, wherein emulsifier concentration is 1.8%, regulate the pH value of emulsifier aqueous solution with potassium hydroxide or potassium dihydrogen phosphate. Premixed by strong mechanical stirring for 25 minutes, then transferred to an emulsification tank, emulsified by shearing machine for 20 minutes, with a line speed of 7.3 m / s, to obtain an O / W emulsion. Pump it into the evaporator for desolvation by vacuum distillation, wherein the temperature of the emulsion is 70°C, the vacuum in the evaporator is 55 kPa, the vacuum distillation stops after 60 minutes, and the residual value of hydrocarbon solvent in the emulsion is determined to be 530ppm. Then pump it into the vacuum membrane distillation device to further remove the hydrocarbon solvent, in which the feed liquid, that is, the emulsion flows through the shell side of the membrane module, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com