High strength and high toughness PVC pipe and preparation method thereof

A high-strength and high-toughness technology for PVC pipes, applied in the field of PVC pipes and its preparation, can solve the problems of poor pressure resistance, limited use range, and low tensile strength of pipes, and achieve improved pressure resistance, low cost, and simple processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

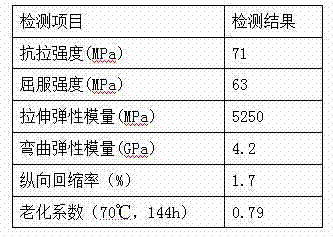

Image

Examples

Embodiment Construction

[0014] A high-strength and high-toughness PVC pipe, made of the following raw materials in weight (kg): SG-3 type PVC 75, bisphenol A type cyanate resin 18, lead sulfide 3, cyclohexane-1,2-dicarboxylate Diisononyl acid 12, aluminum borate whisker 16, polyetherimide 18, neoprene rubber 12, attapulgite 18, barium titanate 14, pumice powder 8, triacetyl ricinoleate 12, Behenic acid amide 4, peat wax 5, di-n-octyltin dilaurate 2, zinc p-toluene sulfinate 1.5, trinonylphenyl phosphite 2.5, 4,4'-thiobis(6-tert-butyl- 3-methylphenol) 1.5, auxiliary agent 5.5;

[0015] The preparation method of the auxiliary agent is as follows: a. Take the following raw materials by weight (kg): Sorbitan Olivate 2.5, Microencapsulated Rose Essential Oil 0.7, Nano Indium Tin Oxide 4, Molybdenum Dialkyl Dithiophosphate 1.5 , polyethylene glycol dimethacrylate 5, aluminum silicate 6, bis(dioctyloxypyrophosphate) ethylene titanate 1.5, diatomaceous earth powder 4, salicylanilide 1.5, 2-tert But...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com