Phosphorus-containing high-temperature-resistant drilling-fluid viscosity reducer and preparation method thereof

A technology of viscosity reducer and drilling fluid, applied in the field of phosphorus-containing anti-high temperature drilling fluid viscosity reducer and its preparation, can solve the problems of high price, difficult to apply on a large scale, difficult to source, etc. The effect of sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

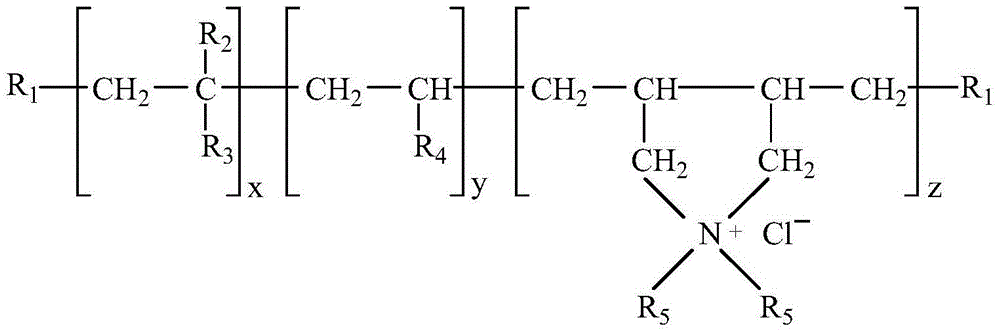

Image

Examples

Embodiment 1

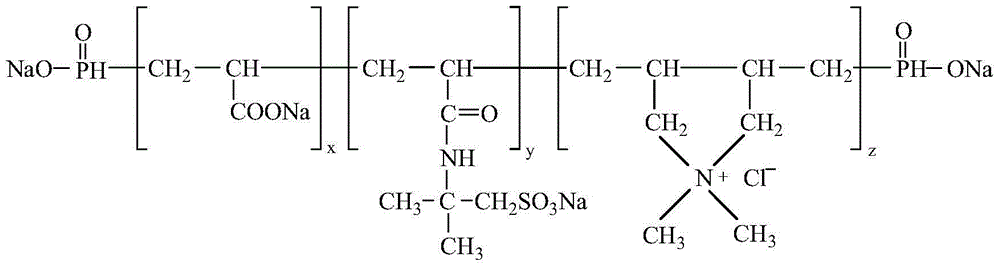

[0019] Dissolve 10g of acrylic acid, 8g of 2-acrylamido-2-methylpropanesulfonic acid, 1g of sodium hypophosphite and 1g of dimethyl diallyl ammonium chloride in 50g of water for later use, and dissolve 0.1g of ammonium persulfate in 30g of Clear water is ready for use, add the monomer solution of the mixture into a four-necked flask and raise the temperature to 50°C, then add the ammonium persulfate solution into the reaction system, raise the temperature of the system to 90°C and react for 1 hour to obtain a viscosity reducer with a solid phase content of 20% The product, after the reaction, neutralizes the pH value of the system with sodium hydroxide to 8, and obtains a phosphorus-containing anti-high temperature drilling fluid viscosity reducer with an average molecular weight of about 20,000 after drying and crushing. Its structural formula is:

[0020]

[0021] The amount ratio of x:y:z substances is 13.9:3.9:0.6.

Embodiment 2

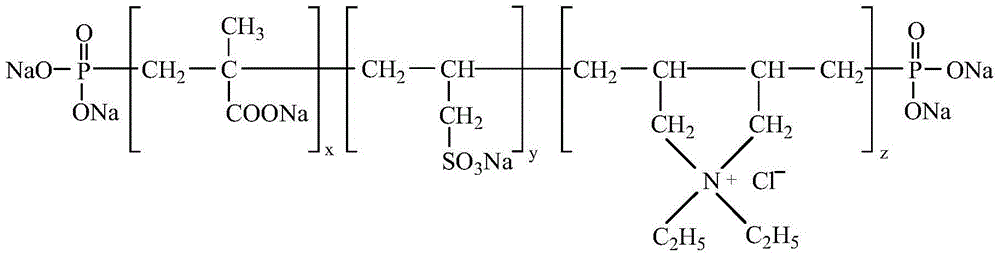

[0023] Dissolve 10g of methacrylic acid, 7g of sodium allyl sulfonate, 0.5g of sodium phosphite and 2.5g of diethyl diallyl ammonium chloride in 15g of clear water for later use, and dissolve 0.5g of ammonium persulfate in 5g of clear water for later use For use, add the monomer solution of the mixture into a four-necked flask and raise the temperature to 40°C, then add the ammonium persulfate solution into the reaction system, raise the temperature of the system to 95°C for 2 hours, and obtain a viscosity reducer product with a solid phase content of 50%. After the reaction, use sodium hydroxide to neutralize the pH value of the system to 9. After drying and crushing, a phosphorus-containing anti-high temperature drilling fluid viscosity reducer with an average molecular weight of about 15,000 is obtained. Its structural formula is:

[0024]

[0025] The amount ratio of x:y:z substances is 11.6:4.9:1.3.

Embodiment 3

[0027] Dissolve 10g of itaconic acid, 5g of 2-acryloyloxybutyl sulfonic acid, 2g of sodium phosphite and 3g of diethyldiallyl ammonium chloride in 150g of water for later use, and dissolve 1g of ammonium persulfate in 30g of clear water for later use , adding the monomer solution of the mixture into a four-necked flask and raising the temperature to 60°C, then adding the ammonium persulfate solution into the reaction system, raising the temperature of the system to 100°C for 1.5 hours to obtain a viscosity reducer product with a solid phase content of 10%, After the reaction, use sodium hydroxide to neutralize the pH value of the system to 8.5. After drying and crushing, a phosphorus-containing anti-high temperature drilling fluid viscosity reducer with an average molecular weight of about 8000 is obtained. Its structural formula is:

[0028]

[0029] The amount ratio of x:y:z substances is 7.7:2.4:1.6.

[0030] Embodiment 4~9 steps are identical with embodiment 1, and reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com