Method for producing proline aminopeptidase by culturing recombinant escherichia coli in high density

A technology for recombining Escherichia coli and proline aminopeptidase is applied in the field of microbial fermentation, which can solve the problems of limited feedback feeding strategy application and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1 fermentation medium and fermentation condition optimization

[0037] (1) Optimization of fermentation medium

[0038] Determination of glucose, yeast extract, peptone, Mg by single factor test2+ The optimal amount of addition, and the specific enzyme activity as the response value, glucose, yeast extract, peptone and Mg 2+ As a factor, choose 4 factors 3 levels L 9 (3 4 ) orthogonal table to test, determine the best enzyme-producing medium as 5g / L glucose (sterilized separately at 115 ℃), 20g / L tryptone, 30g / L yeast extract, 12.54g / LK 2 HPO 4 , 2.31g / LKH 2 PO 4 , adding Mg after sterilization 2+ The final concentration is 7.5mmol·L -1 , pH7.2.

[0039] (2) Optimization of fermentation conditions

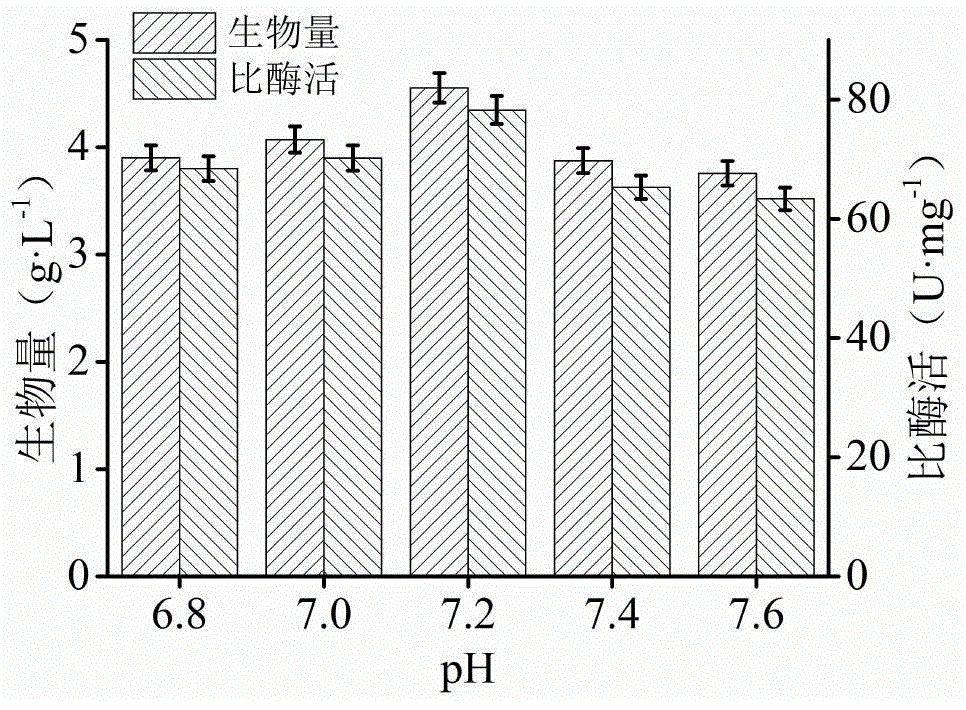

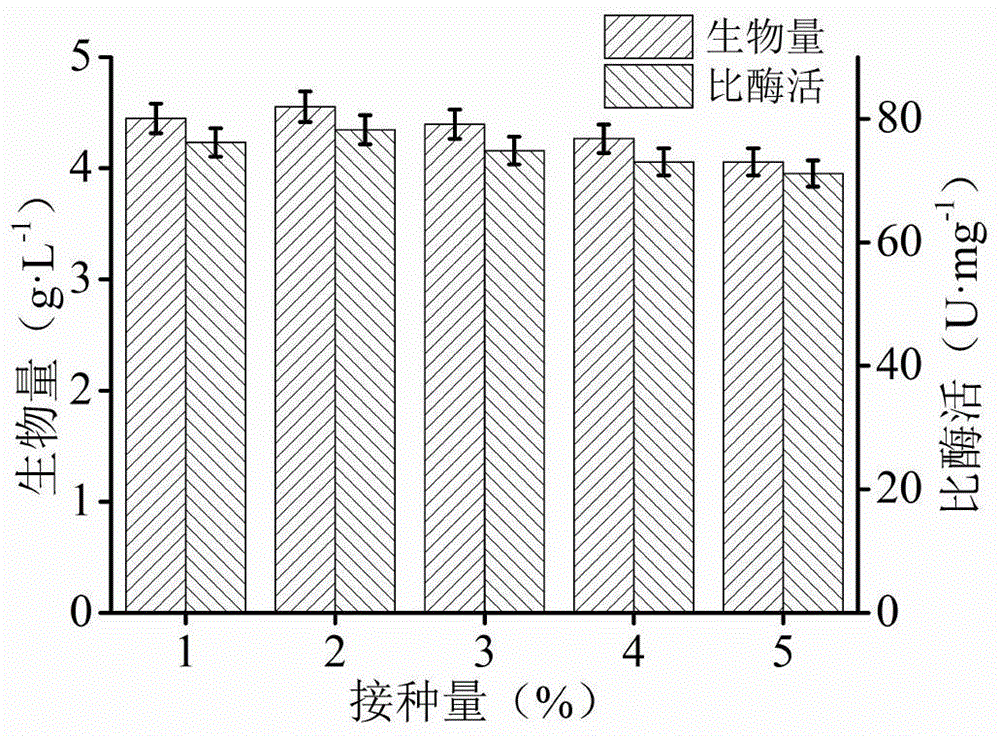

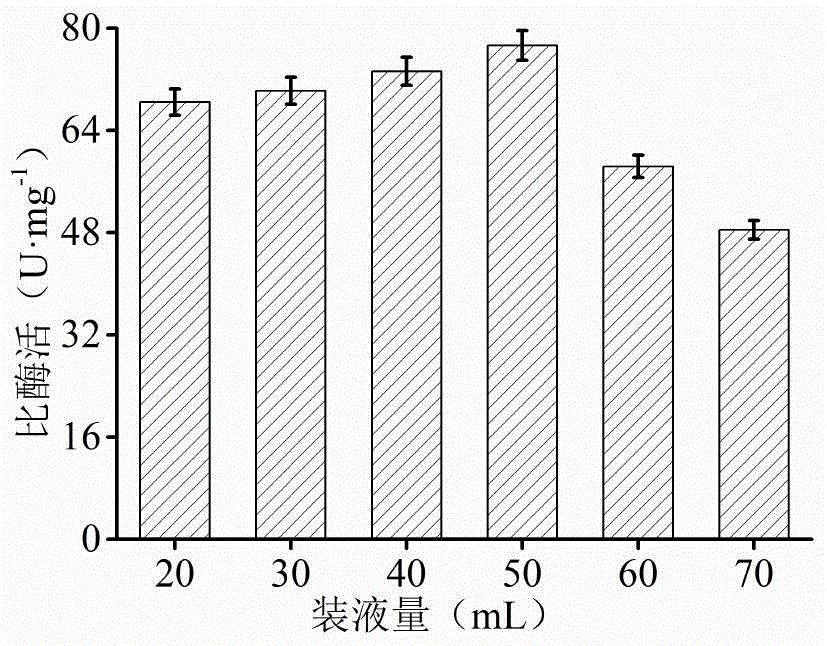

[0040] The amount of inducer added, the timing of induction, the induction time, the initial pH of the fermentation broth, the amount of inoculum and the amount of liquid were optimized. the result shows( Figure 1-6 ): The optimal enzyme production con...

Embodiment 2

[0041] Embodiment 2 Recombinant bacteria are fermented at a high density on a 7L fermenter

[0042] (1) batch fermentation

[0043] Add 4L high-density fermentation medium to 7L Zhenjiang Dongfang GBJT-7C fermenter. After sterilization, add antibiotics and a final concentration of 0.75 mmol L -1 Mg 2+ . Inoculate 80 mL of seed culture in logarithmic phase with 2% inoculum size, culture at 37° C., and maintain rotation speed at 500 rpm and ventilation at 3 vvm. When it is detected that the glucose in the fermentation broth is exhausted, start to add the final concentration of 3g L -1 induced by lactose. Such as Figure 7 As shown, 8h after inoculation, glucose was exhausted, and at this time, lactose was added for induction. After 12h of induction, the expression of protein reached the highest value of 91.89U / mg, and the cell density (OD 600 ) reached 15.60.

[0044] (2) Fed-batch fermentation

[0045] When the fermentation culture is carried out in a batch fermentatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com