Method for preparing perovskite coating of metallic interconnector by cold spraying and product prepared by same

A metal connector and perovskite technology, which is applied in the field of metal connector perovskite coating prepared by cold spraying, can solve the problems that hinder the development and commercialization of SOFC technology, the coating is difficult to sinter completely, and the product quality is affected. Achieve the effect of low production cost, broad market space, and low requirements for production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) Metal substrate treatment: take a ferritic stainless steel plate with a thickness of 1mm, and wire cut it into a sample with a size of 25mm×25mm. Use 200~1500 on the surface of the metal substrate # Sandpaper was polished step by step, and soaked in citric acid solution for 20 minutes to improve its surface activity, then ultrasonically cleaned in alcohol for 15 minutes, and dried for later use;

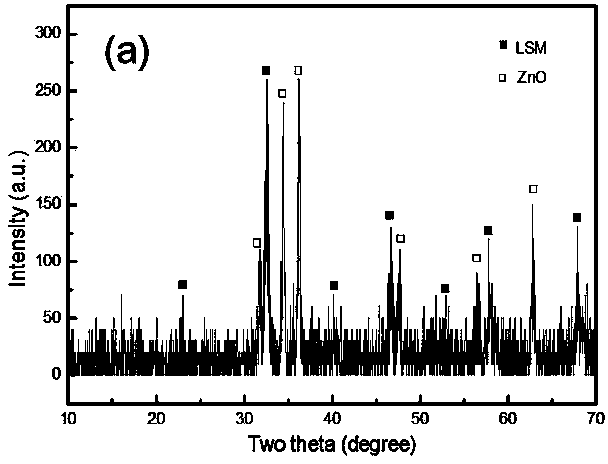

[0026] 2) Preparation of LSM-Zn cold spray slurry: nanoscale La 0.8 Sr 0.2 MnO 3 Powder, micron-sized metal Zn powder (purity 99.9%), and terpineol are mixed. The mixing ratio is: the mass ratio of LSM powder to Zn powder is 9:1, and the volume ratio of powder to terpineol is 1. :1. The above raw materials are ball milled on a planetary ball mill, the ball milling speed is 200r / min, and the ball milling time is 24h;

[0027] 3) Preparation process of LSM coating:

[0028] Spray the above-mentioned LSM-Zn slurry on the surface of the pretreated metal connector sample a...

Embodiment 2

[0030] 1) Metal substrate treatment: take a ferritic stainless steel plate with a thickness of 1mm, and wire cut it into a sample with a size of 25mm×25mm. Use 200~1500 on the surface of the metal substrate # The sandpaper was polished step by step, soaked in citric acid solution for 20 minutes to improve its surface activity, then ultrasonically cleaned in alcohol for 15 minutes, and dried for later use.

[0031] 2) Preparation of LSM-Zn cold spray slurry: nanoscale La 0.8 Sr 0.2 MnO 3 Powder, micron metal Zn powder (purity 99.9%), terpineol for mixing. The mixing ratio is: the mass ratio of LSM powder to Zn powder is 7:1, and the volume ratio of powder to terpineol is 1:1.5. The above-mentioned raw materials were ball-milled on a planetary ball mill, the ball milling speed was 300r / min, and the ball milling time was 16h.

[0032] 3) Preparation process of LSM coating:

[0033] Spray the above-mentioned LSM-Zn slurry on the surface of the pretreated metal connector samp...

Embodiment 3

[0035] 1) Metal substrate treatment: take a ferritic stainless steel plate with a thickness of 1mm, and wire cut it into a sample with a size of 25mm×25mm. Use 200~1500 on the surface of the metal substrate # The sandpaper was polished step by step, soaked in citric acid solution for 20 minutes to improve its surface activity, then ultrasonically cleaned in alcohol for 15 minutes, and dried for later use.

[0036] 2) Preparation of LSM-Zn cold spray slurry: nanoscale La 0.8 Sr 0.2 MnO 3 Powder, micron metal Zn powder (purity 99.9%), terpineol for mixing. The mixing ratio is: the mass ratio of LSM powder to Zn powder is 6:1, and the volume ratio of powder to terpineol is 1:2. The above-mentioned raw materials were ball milled on a planetary ball mill at a ball milling speed of 400 r / min and a ball milling time of 8 hours.

[0037] 3) Preparation process of LSM coating:

[0038] Spray the above-mentioned LSM-Zn slurry on the surface of the pretreated metal connector sample...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com