A kind of preparation method of porous graphene supported transition metal nanocomposite catalyst

A porous graphene and transition metal technology, applied in the field of electrochemical catalysis, can solve the problems of limited three-phase catalytic reaction area, material waste, and inability to significantly improve the catalytic activity of the electrode, and achieve excellent catalytic activity, abundant sources, and good water permeability Effect of breathability properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Preparation of self-generated porous bamboo charcoal or charcoal: calcining shavings or scraps of bamboo and pine wood at high temperature (1500 degrees Celsius) for 0.5 hours in an oxygen-deficient atmosphere.

[0021] (2) Preparation of iron nanoparticles: immerse the bamboo charcoal or charcoal prepared in step (1) into a solution containing iron ions (concentration 0.01mol / L) for 1000 minutes, take out the bamboo charcoal or charcoal and put it into an anoxic atmosphere again at high temperature (1000 degrees Celsius) calcined for 0.5 hours.

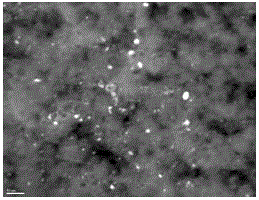

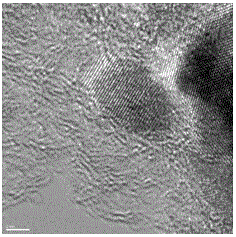

[0022] (3) preparation of porous graphene: this bamboo charcoal or charcoal that step (2) is made is immersed in strong oxidizing solution 24 hours, makes graphite structure fully oxidized to graphite oxide; Take out this bamboo charcoal or charcoal under high temperature ( 1000 degrees Celsius) for 0.01 hours of calcination.

[0023] The above strong oxidizing solution is a mixed solution of 1g sodium nitrate, 46mL sulfu...

Embodiment 2

[0025] Others are the same as in Example 1, the transition metal ion solution immersed is a solution containing nickel ions.

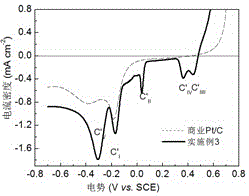

Embodiment 3

[0027] Others are the same as in Example 1, the transition metal ion solution immersed is a solution containing cobalt ions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com