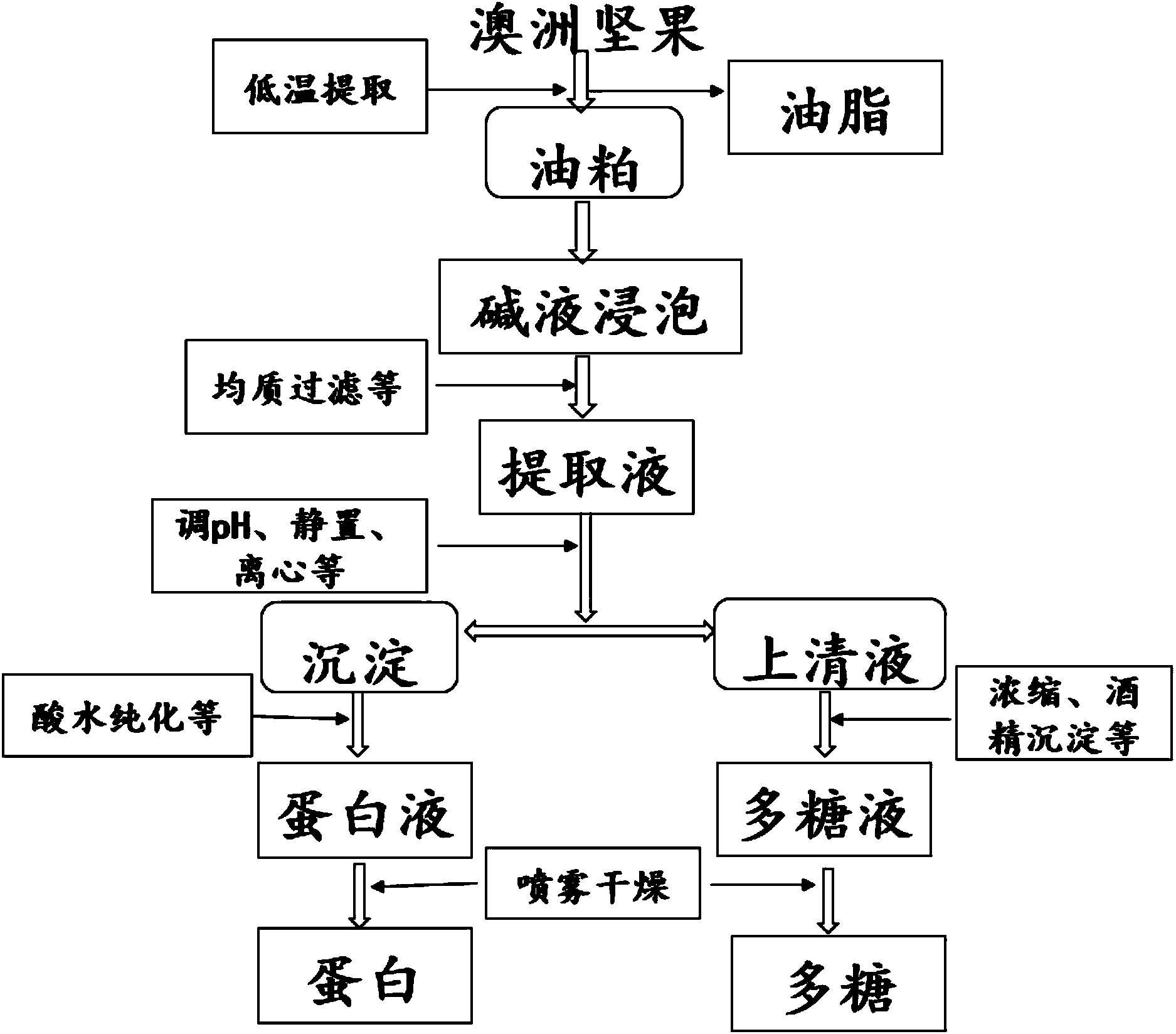

Separation method for coproducing macadimia nut polysaccharide and albumen

A separation method and fructose polysaccharide technology, applied in the field of plant extraction, can solve the problems of low utilization value of oil meal, difficult to obtain mechanically, and not used, and achieve the effects of good biological activity and functional properties, avoiding denaturation, and being easy to implement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Preparation of oil meal: crush shelled macadamia nut kernels through a 10-mesh sieve, weigh 10Kg and place it in the barrel of a 15L extraction kettle, and make it dry at 45°C, 35MPa, CO 2 The macadamia nut oil was extracted under the condition of a flow rate of 15L / h.Kg nut flour. After the extraction, the oil meal was taken out and the CO 2 Fully volatilize to obtain 4Kg of oil-free macadamia nut oil meal;

[0042] (2) Soaking in alkaline solution: crush the oil-free macadamia nut oil meal obtained in step (1), pass through a 10-mesh sieve, add 36Kg of water and stir evenly, then adjust the pH value to 9.2 with 1mol / L NaOH solution, and put it under room temperature Stand still for 12 hours, stir 3 times during this period, and then use a colloid mill to homogenize once to obtain a homogeneous solution;

[0043] (3) Extraction: the homogeneous solution obtained in step (2) is filtered on a bag filter to obtain a clarified extract;

[0044] (4) Adjust the pH valu...

Embodiment 2

[0050](1) Preparation of oil meal: crush shelled macadamia nut kernels through a 100-mesh sieve, weigh 20Kg and place it in the barrel of a 30L extraction kettle, make it in n-butanol as a subcritical solvent, at 0.5MPa, 40°C, The macadamia nut oil was extracted under subcritical conditions with an extraction time of 5 minutes, and the extraction was repeated 3 times. After the oil was extracted, the oil meal was taken out to fully volatilize the n-butane to obtain 6Kg of oil-free macadamia oil meal;

[0051] (2) Soaking in alkaline solution: crush the oil-free macadamia nut oil meal obtained in step (1), pass through a 50-mesh sieve, add 70Kg1N NaOH solution, stir evenly (pH is 15), let stand at room temperature for 18 hours, and stir during the period 4 times, then use a colloid mill to homogenize once to obtain a homogeneous solution;

[0052] (3) Extraction: the homogeneous solution obtained in step (2) is filtered on a plate and frame filter to obtain a clarified extract;...

Embodiment 3

[0059] (1) Preparation of oil meal: crush shelled macadamia nut kernels through a 40-mesh sieve, weigh 5Kg and place it in the barrel of a 10L extraction kettle, make it in n-propane as a subcritical solvent, extract at 0.5MPa, 40°C, The macadamia nut oil was extracted under subcritical conditions for 5 minutes, and the extraction was repeated 3 times. After the oil was extracted, the oil meal was taken out to fully volatilize the n-butane to obtain 1Kg of oil-free macadamia oil meal;

[0060] (2) Soaking in alkaline solution: crush the oil-free macadamia nut oil meal obtained in step (1), pass through a 100-mesh sieve, add 10Kg of water, stir evenly, and then adjust the pH value to 10 with 1mol / L NaOH solution. Stand still for 24 hours, stir 5 times during this period, and then use a colloid mill to homogenize once to obtain a homogeneous solution;

[0061] (3) Extraction: the homogeneous solution obtained in step (2) was centrifuged at 6000rpm for 15 minutes;

[0062] (4) A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com