Novel glutinous rice emulsion used for coating

An emulsion and paint technology, applied in the field of paint, can solve the problems of memory loss, health injury, non-compliance with environmental protection, etc., and achieve the effects of high environmental protection level, improved gloss, gloss and color development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

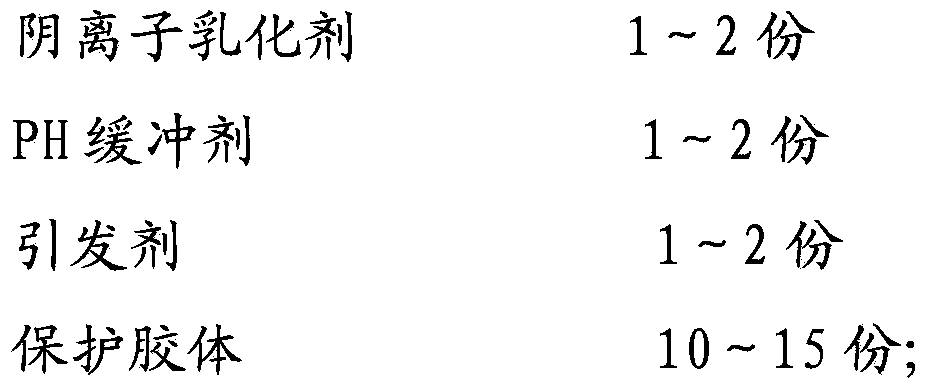

[0041] Described emulsion A is made up of following by mass:

[0042]

[0043] The glutinous rice pulp B comprises the following components by mass and is prepared according to the following method:

[0044]

[0045] ① Add water, glutinous rice flour, quicklime, and brown sugar to the reactor according to the recipe, and heat up to 60°C while stirring for more than 30 minutes;

[0046] ②Stop stirring, naturally cool to room temperature, and set aside;

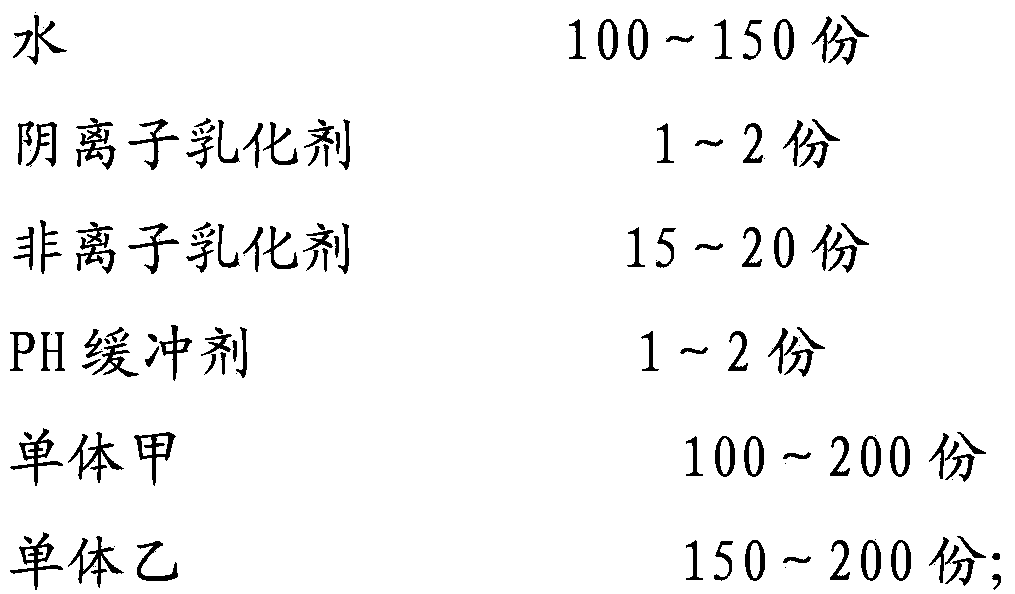

[0047] The monomer pre-emulsion C is composed of the following by mass and is prepared according to the following method:

[0048]

[0049] ① Mix water, sodium dodecylbenzene sulfonate, ethoxylated fatty alcohol, and baking soda and stir;

[0050] ② Add vinyl tertiary carbonate and 2-ethyl ethyl acrylate under stirring, and continue stirring for 10 minutes to obtain monomer pre-emulsion;

[0051] Described initiator solution D is made up of following by mass:

[0052] 50-80 parts of water

[0053] Potassium persul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com