Method for extracting vanadium from high-calcium vanadium-containing materials

A material and high-calcium technology, applied in the field of vanadium metallurgy, can solve the problems that the vanadium leaching rate is difficult to reach more than 25%, increase production costs, increase costs, etc., and achieve the effects of reduced production costs, high recovery rate, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1 adopts the inventive method to extract vanadium from vanadium-containing tailings

[0046] 1. Test raw materials

[0047] (1) The chemical composition of vanadium-containing tailings is shown in Table 1.

[0048] Table 1 Chemical composition (wt%) of vanadium-containing tailings

[0049] Element

V 2 o 5

Ca0

SiO 2

Cr 2 o 3

P

TF

content

3.6

25

7.6

2

0.8

35.4

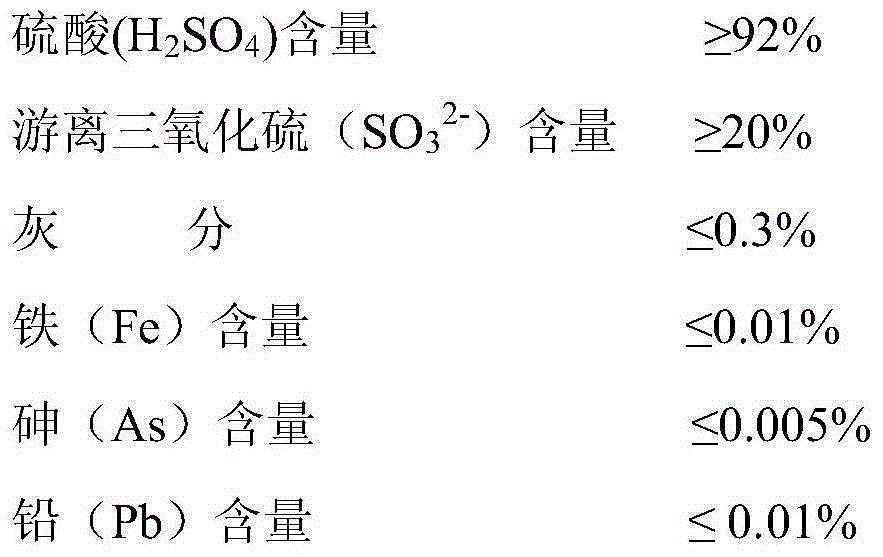

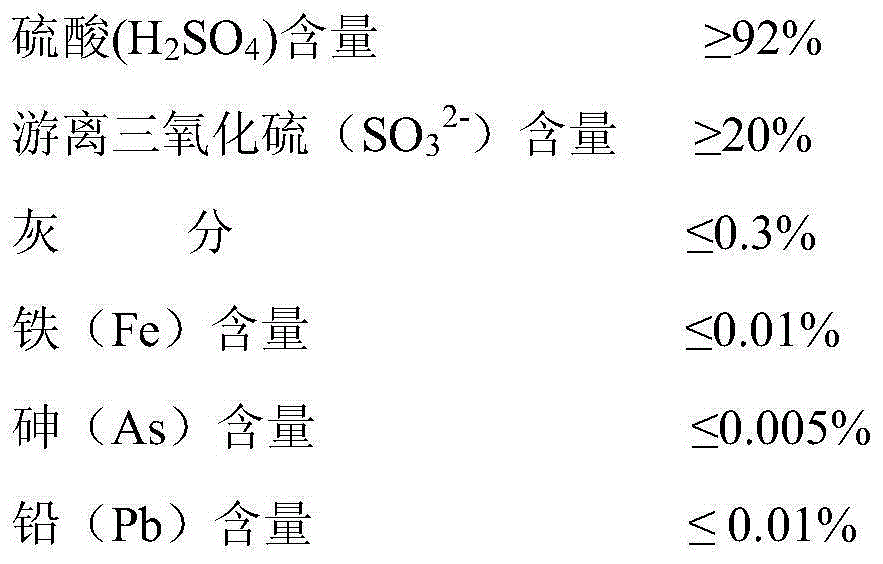

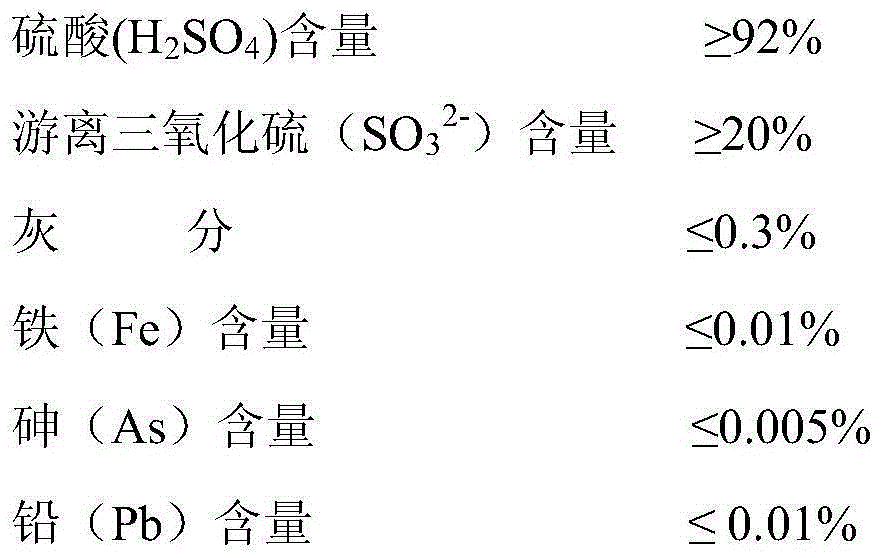

[0050] (2) Specifications of sulfuric acid: industrial sulfuric acid

[0051]

[0052] (3) Reducing agent: Na 2 S 2 o 5

[0053] (4) Vanadium precipitation agent: NH 4 HCO 3

[0054] 2. Test method

[0055] (1) Reductive acid leaching of vanadium-containing materials

[0056] Vanadium-containing material 125Kg (dry basis weight), by weight, water: vanadium-containing material=4: 1, add water in the vanadium-containing material, then add 11L of sulfuric acid with a concentration of 92%, then add 3Kg of reducin...

Embodiment 2

[0060] Embodiment 2 adopts the method of the present invention to extract vanadium from vanadium-containing tailings

[0061] Carry out according to the method in embodiment 1, reducing agent adopts Na 2 S 2 o 4 .

[0062] Reductive acid leaching of vanadium-containing materials, V in the solid 2 o 5 0.8%, vanadium yield 78%.

[0063] The total recovery rate of vanadium=73.9%, the purity V of vanadium pentoxide 2 o 5 : 52.45%, P: 0.92%, Fe: 20.64%, Si: 3.2%. Example 3 Using the method of the present invention to extract vanadium from vanadium-containing tailings

Embodiment 3

[0063] The total recovery rate of vanadium=73.9%, the purity V of vanadium pentoxide 2 o 5 : 52.45%, P: 0.92%, Fe: 20.64%, Si: 3.2%. Example 3 Using the method of the present invention to extract vanadium from vanadium-containing tailings

[0064] Carry out according to the method in embodiment 1, reducing agent adopts Na 2 SO 3 .

[0065] Reductive acid leaching of vanadium-containing materials, V in the solid 2 o 5 0.85%, vanadium yield 77.8%. The total recovery rate of vanadium=73.7%, the purity of vanadium pentoxide: V 2 o 5 (42.68%), P (0.94%), Fe (20.48%), Si (2.5%).

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com