All-solid-state sensitized solar cell and preparation method thereof

A solar cell, all-solid-state technology, applied in the field of dye-sensitized solar cells, can solve problems such as reducing electron injection efficiency, and achieve the effects of improving photoelectric conversion efficiency, increasing electron injection efficiency, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Example 1, preparation of all solid-state sensitized solar cells

[0056] 1) Preparation of photoanode

[0057] Preparation of dense film layer and porous film layer:

[0058] Prepare according to conventional methods, and can be prepared according to the methods provided in the following documents: Lead Iodide Perovskite Sensitized All-Solid-State Submicron Thin Film Mesoscopic Solar Cell with Efficiency Exceeding9%, H.S.Kim, C.R.Lee, J.H.Im, K.B.Lee, T .Moehl, A.Marchioro, S.J.Moon, R.Humphry-Baker, J.H.Yum, J.E.Moser, M.Gratzel and N.G.Park, Scientific Reports, 2012, 2,591. The specific steps are:

[0059] a. A dense titanium dioxide film was prepared by spin coating, and the precursor solution of the dense film was coated on the surface of the conductive glass, and the film was spinned for 30 seconds at a rotational speed of 2000 rpm. Immediately after the end, place the film on a hot plate preheated to 80°C for 30 minutes; the thickness of the dense film layer is...

Embodiment 2

[0077] Example 2, preparation of all solid-state sensitized solar cells

[0078] Follow exactly the same steps as in Example 1, only the hole transport layer in step 3) is replaced by PTAA, and the composition of the hole transport material is as follows: PTAA, 4-tert-butylpyridine, bistrifluoromethanesulfonimide The ratio of lithium acetonitrile solution to chlorobenzene is 0.18 g: 17.5 μL: 37.5 μL: 1 mL, and the concentration of the acetonitrile solution of lithium bistrifluoromethanesulfonimide is 170 mg / mL.

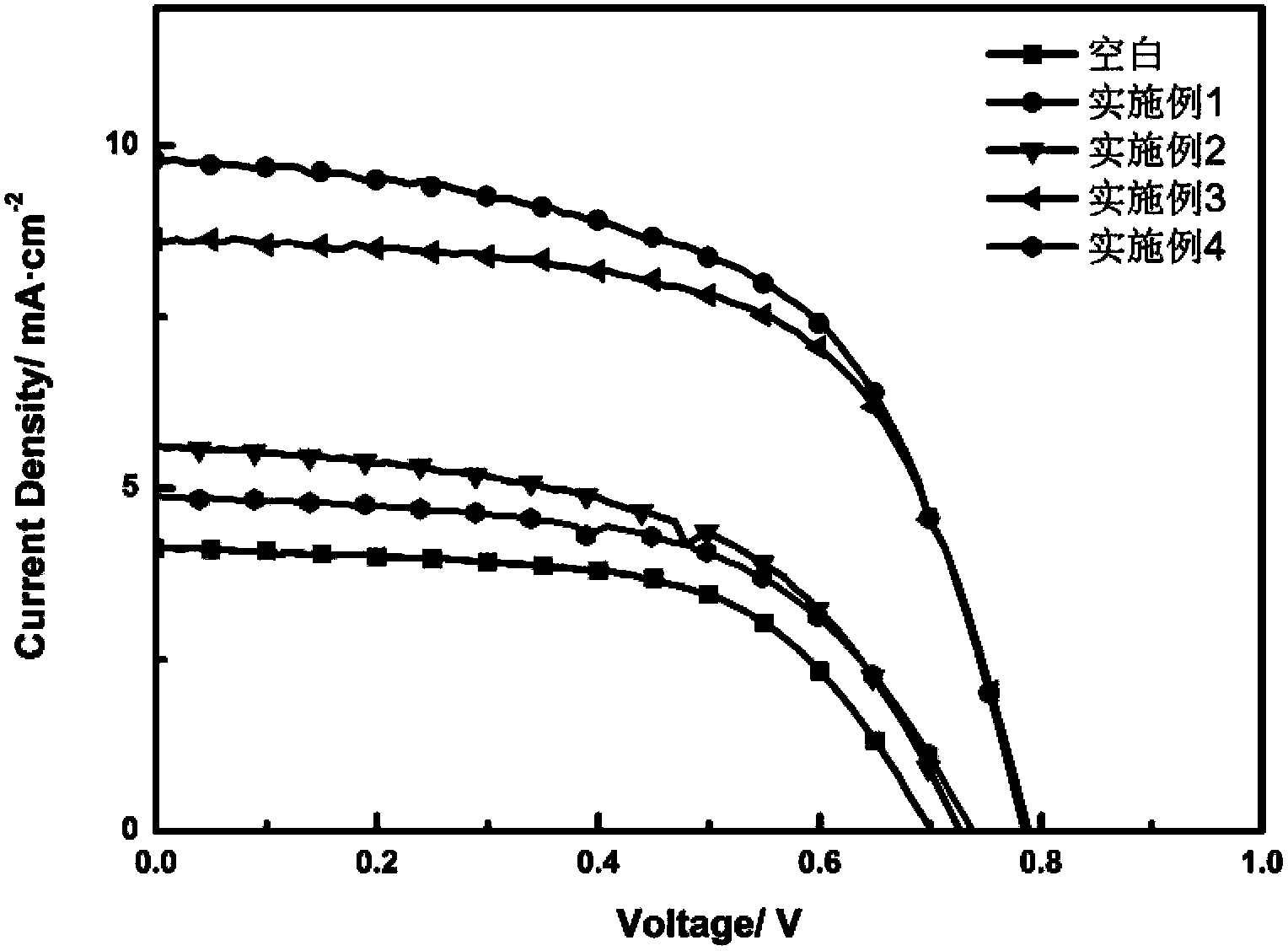

[0079] In AM1.5, 100mW / cm 2 Test the I-V performance curve of the battery with KEITHLEY4200 under light, such as figure 1 As shown in , the short-circuit current density of the battery is 5.6mA / cm 2 , the open circuit voltage is 0.725V, the fill factor is 0.534, and the photoelectric conversion efficiency is 2.17%.

Embodiment 3

[0080] Example 3, preparation of all solid-state sensitized solar cells

[0081] Follow exactly the same steps as in Example 1, only the preparation method of the sensitizer layer in step 1) is changed, PbI 2 and CH 3 NH 3 At the same time, I is used as a thermal evaporation source and evaporated onto the surface of the titanium dioxide film.

[0082] In AM1.5, 100mW / cm 2 Test the I-V performance curve of the battery with KEITHLEY4200 under light, such as figure 1 As shown in , the short-circuit current density of the battery is 8.6mA / cm 2 , the open circuit voltage is 0.785V, the fill factor is 0.626, and the photoelectric conversion efficiency is 4.23%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com