G-C3N4/activated carbon compound photo-catalyst as well as preparation method and application of g-C3N4/activated carbon compound photo-catalyst

A technology of g-c3n4 and activated carbon, which is applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as ineffective use of sunlight, high exciton binding energy, and large band gap , to achieve maximum application value, increase specific surface area, and improve dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) The powdery activated carbon is boiled and cleaned with 0.01mol / L nitric acid, then washed with distilled water until neutral, and dried in an oven to constant weight;

[0019] (2) Get the gac of a certain amount of step (1) and mix with urea and ammonium chloride, fully grind; Move in the tubular quartz reactor, under the protection of high-purity nitrogen, in the rotary kiln, rise to the speed of 5 ℃ / min 210°C, and keep the temperature for 10 minutes; then rise to 240°C at a rate of 1°C / min, and hold the temperature for 20 minutes; then rise to 250°C at a rate of 0.1°C / min, and hold the temperature for 30 minutes; then rise to 2°C / min at a rate of 480°C, keep the temperature for 1h, then raise it to 550°C at a rate of 1°C / min, and keep the temperature for 2h, then cool it down to room temperature and take it out to obtain the g-C 3 N 4 / Activated carbon composite photocatalyst, wherein the content of activated carbon is 3%.

Embodiment 2

[0021] (1) Boil and clean the powdered activated carbon with 0.01mol / L nitric acid, then wash it with distilled water until neutral, and dry it in an oven to constant weight;

[0022] (2) Get the gac of a certain amount of step (1) and mix with urea and ammonium chloride, fully grind; Move in the tubular quartz reactor, under the protection of high-purity nitrogen, in the rotary kiln, rise to the speed of 5 ℃ / min 210°C, and keep the temperature for 10 minutes; then rise to 240°C at a rate of 1°C / min, and hold the temperature for 20 minutes; then rise to 250°C at a rate of 0.1°C / min, and hold the temperature for 30 minutes; then rise to 2°C / min at a rate of 480°C, keep the temperature for 1h, then raise it to 550°C at a rate of 1°C / min, and keep the temperature for 2h, then cool it down to room temperature and take it out to obtain the g-C 3 N 4 / Activated carbon composite photocatalyst, wherein the content of activated carbon is 8%.

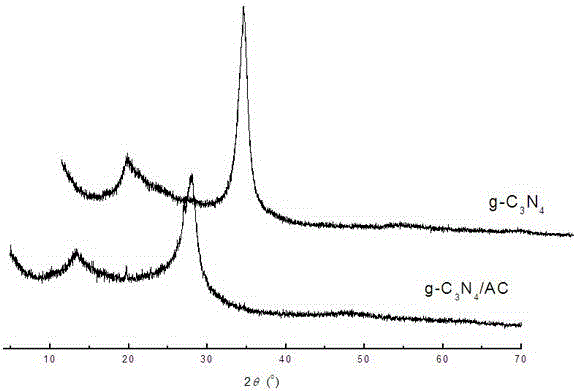

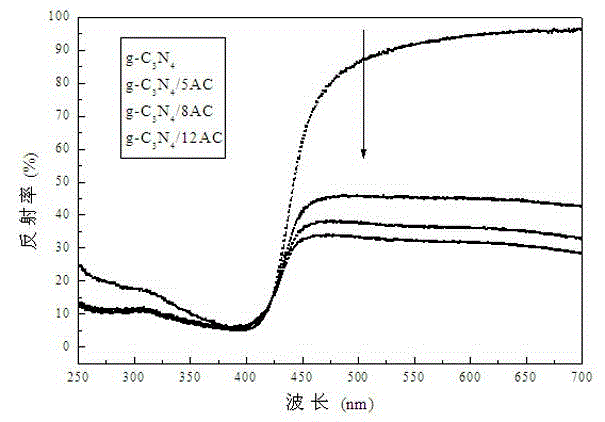

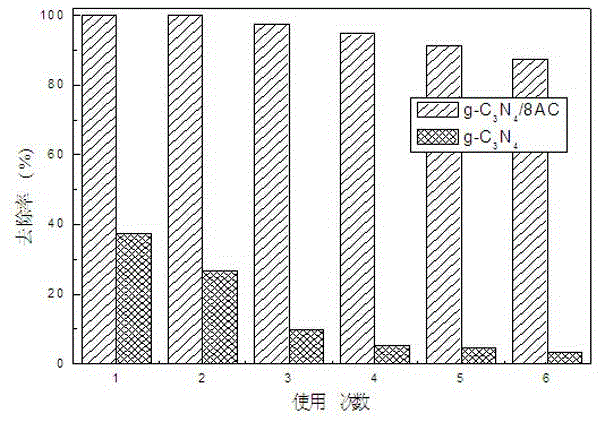

[0023] figure 1 for g-C 3 N 4 and g-...

Embodiment 3

[0028] (1) Boil and clean the powdered activated carbon with 0.01mol / L nitric acid, then wash it with distilled water until neutral, and dry it in an oven to constant weight;

[0029] (2) get the gac of a certain amount of step (1) and mix with urea and ammonium chloride, fully grind; Move in the tubular quartz reactor, under the protection of high-purity nitrogen, in the rotary kiln, rise to the speed of 5 ℃ / min 210°C, and keep the temperature for 10 minutes; then rise to 240°C at a rate of 1°C / min, and hold the temperature for 20 minutes; then rise to 250°C at a rate of 0.1°C / min, and hold the temperature for 30 minutes; then rise to 2°C / min at a rate of 480°C, keep the temperature for 1h, then raise it to 550°C at a rate of 1°C / min, and keep the temperature for 2h, then cool it down to room temperature and take it out to obtain the g-C 3 N 4 / Activated carbon composite photocatalyst, wherein the content of activated carbon is 15%.

[0030] Catalytic degradation experiment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com