Preparation method of comb-shaped polymer phase change energy storage material

A technology of phase change energy storage material and comb-like polymer, which is applied in heat exchange materials, chemical instruments and methods, etc., can solve the problems of poor processing performance, narrow application range and low enthalpy value of comb-like phase change materials. , to achieve the effect of high yield, overcoming flow leakage, convenient and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

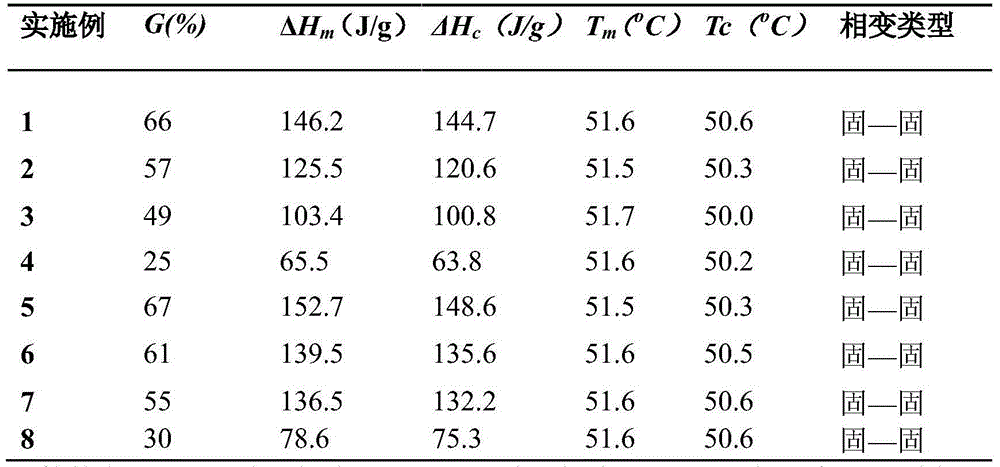

Embodiment 1

[0029] A preparation method of a comb polymer phase change energy storage material, comprising the steps of:

[0030] Add 3% of its mass of CaH to toluene 2 Carry out vacuum distillation to remove water, obtain anhydrous toluene for subsequent use;

[0031] Then the polyethylene grafted maleic anhydride and n-octadecyl alcohol of 1:2 are joined in the there-necked flask with mechanical stirring, thermometer, reflux condenser, nitrogen protection, then add catalyzer p-toluenesulfonic acid ( The consumption of p-toluenesulfonic acid is 5% of polyethylene graft maleic anhydride and n-octadecyl alcohol quality and), and toluene (the concentration of polyethylene graft maleic anhydride and n-octadecyl alcohol in toluene is 15wt%) , raised the temperature to 80°C, mechanically stirred and refluxed for 8 hours, cooled down, removed the solvent, washed, and dried to obtain a pure comb-like polymer phase-change energy storage material.

[0032] Using NETZSH DSC 200F3 differential sca...

Embodiment 2

[0038] Adjust the molar ratio of polyethylene grafted maleic anhydride to n-stearyl alcohol in Example 1 to be 1:1.5 and the rest of the conditions are the same as those in Example 1, and the properties of the prepared comb polymer phase-change energy storage material are listed in Table 1.

Embodiment 3

[0040] Adjust the molar ratio of polyethylene grafted maleic anhydride and n-octadecyl alcohol to 1:1 in Example 1, and the rest of the conditions are the same as in Example 1. The properties of the prepared comb polymer phase-change energy storage material are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting temperature | aaaaa | aaaaa |

| Crystallization temperature | aaaaa | aaaaa |

| Onset thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com